Shamol turbinasi dizayni - Wind turbine design

Shamol turbinasi dizayni ning shakli va texnik xususiyatlarini aniqlash jarayoni shamol turbinasi dan energiya olish uchun shamol.[1]Shamol turbinasi qurilmasi shamol energiyasini olish, turbinani shamolga yo'naltirish va konvertatsiya qilish uchun zarur bo'lgan tizimlardan iborat. mexanik aylanish ichiga elektr quvvati va turbinani ishga tushirish, to'xtatish va boshqarish uchun boshqa tizimlar.

Ushbu maqola dizaynini o'z ichiga oladi gorizontal o'qli shamol turbinalari (HAWT), chunki savdo turbinalarning aksariyati ushbu dizayndan foydalanadi.

1919 yilda fizik Albert Betz gipotetik ideal shamol energiyasini qazib olish mashinasi uchun massa va energiyani saqlashning asosiy qonunlari shamolning kinetik energiyasining 16/27 (59,3%) dan ko'pini olishga imkon berganligini ko'rsatdi. Bu Betz qonuni chegaraga zamonaviy turbinalar konstruktsiyalari yaqinlashishi mumkin, bu nazariy chegaraning 70 dan 80 foizigacha yetishi mumkin.

To'liq shamol energetikasi tizimini loyihalashda pichoqlarning aerodinamik dizayni bilan bir qatorda markaz, boshqaruv elementlari, generator, qo'llab-quvvatlovchi tuzilma va poydevor dizayni ham ko'rib chiqilishi kerak. Shamol turbinalarini elektr tarmoqlariga qo'shishda dizayn bo'yicha boshqa savollar tug'iladi.

Aerodinamik

Shamol turbinasi pichoqlarining shakli va o'lchamlari shamoldan energiyani samarali ravishda chiqarib olish uchun zarur bo'lgan aerodinamik ko'rsatkichlar va pichoqdagi kuchlarga qarshilik ko'rsatish uchun zarur bo'lgan kuch bilan belgilanadi.

Gorizontal o'qli shamol turbinasining aerodinamikasi oddiy emas. Pichoqlardagi havo oqimi turbinadan uzoqda joylashgan havo oqimi bilan bir xil emas. Energiyani havodan olish usulining o'ziga xos xususiyati ham turbinaning ta'siriga havoning tushishini keltirib chiqaradi. Bundan tashqari, rotor yuzasida shamol turbinasi aerodinamikasi boshqa aerodinamik maydonlarda kamdan kam uchraydigan hodisalarni namoyish etadi.

Quvvatni boshqarish

Shamol turbinasining aylanish tezligini samarali energiya ishlab chiqarish va turbin tarkibiy qismlarini mo'ljallangan tezlik va moment chegaralarida saqlash uchun boshqarish kerak. Aylanadigan pichoqlar ustidagi markazdan qochiruvchi kuch aylanish tezligining kvadratiga qarab ko'payadi, bu esa bu strukturani haddan tashqari tezlikka sezgir qiladi. Shamolning quvvati shamol tezligining kubigiga qarab ortib borishi sababli, ular deyarli energiya ishlab chiqarishi mumkin bo'lganlarga qaraganda ancha yuqori shamol yuklarini (masalan, shamol kabi) saqlab qolish uchun turbinalarni qurish kerak. Shamol turbinalarida yuqori shamollarda momentni kamaytirish usullari mavjud.

Shamol turbinasi shamol tezligi oralig'ida quvvat ishlab chiqarishga mo'ljallangan. O'chirish tezligi ko'plab turbinalar uchun 3-4 m / s atrofida, 25 m / s da esa o'chiriladi.[2] Agar shamolning nominal tezligi oshib ketsa, quvvat cheklanishi kerak. Bunga erishishning turli usullari mavjud.

Boshqarish tizimi uchta asosiy elementni o'z ichiga oladi: jarayon o'zgaruvchilarini o'lchash uchun datchiklar, energiyani olish va komponentlarni yuklashni boshqarish uchun aktuatorlar va datchiklar tomonidan to'plangan ma'lumotlarga asoslanib aktuatorlarni muvofiqlashtirish uchun boshqarish algoritmlari.[3]

Barcha shamol turbinalari shamolning maksimal tezligi uchun mo'ljallangan bo'lib, ular tirik qolish tezligi deb ataladi, buning ustiga ular zarar ko'radi. Tijorat shamol turbinalarining omon qolish tezligi 40 m / s (144 km / s, 89 MPH) dan 72 m / s (259 km / s, 161 MPH) oralig'ida. Eng keng tarqalgan omon qolish tezligi 60 m / s (216 km / soat, 134 MPH). Ba'zilar sekundiga 80 metr (290 km / soat; 180 milya) omon qolish uchun mo'ljallangan.[4]

Stall

A tokcha bo'yicha plyonka havo uning ustiga avlod hosil bo'ladigan tarzda o'tganda sodir bo'ladi ko'tarish tez pasayadi. Odatda bu yuqori darajaga bog'liq hujum burchagi (AOA), lekin ayni paytda dinamik effektlardan kelib chiqishi mumkin. Qattiq pog'onali shamol turbinasining pichoqlari aerodinamik ravishda shamolning yuqori tezligida to'xtab turishi va sekinroq aylanishiga olib kelishi mumkin.[5] Bu oddiy va xavfsiz haddan tashqari shamol tezligi tufayli tizimning shikastlanishiga yo'l qo'ymaslik uchun mexanizm. Biroq, dinamik ravishda boshqariladigan balandligi bo'lgan tizimlardan tashqari, u shamol tezligining katta diapazonida doimiy quvvat ishlab chiqara olmaydi, bu esa uni katta miqyosda kamroq moslashtiradi, elektr tarmog'i ilovalar.[6]

Ruxsat etilgan tezlikda HAWT (Landshaft Axis Shamol Turbinasi) pichoqlar tezlashganda shamolning yuqori tezligida hujum burchagini tabiiy ravishda oshiradi. Tabiiy strategiya shundan iboratki, shamol tezligi oshganda pichoqning to'xtab qolishiga imkon berish. Ushbu uslub ko'plab erta HAWTlarda muvaffaqiyatli ishlatilgan. Biroq, ushbu pichoq to'plamlarining ba'zilarida pichoq balandligi darajasi eshitiladigan shovqin darajasini oshirishga intilganligi kuzatildi.

Vortex generatorlari pichoqni ko'tarish xususiyatlarini boshqarish uchun ishlatilishi mumkin. VG'lar, agar ular pastki (tekisroq) yuzaga joylashtirilgan bo'lsa yoki yuqori (yuqori kamber) sirtga qo'yilgan bo'lsa, maksimal ko'tarilishni cheklaydigan liftni kuchaytirish uchun havo plyonkasiga joylashtiriladi.[7]

Furling

Furling hujum burchagini kamaytirish orqali ishlaydi, bu rotorni ko'tarilishidan kelib chiqadigan qarshilikni kamaytiradi, shuningdek kesma. Shamol turbinalarini loyihalashdagi muhim muammolardan biri bu pichoqlarning to'xtab qolishi yoki mo'yna Shamol kuchli to'satdan tezlashishga olib kelishi kerak. To'liq burmali turbinali pichoq, to'xtatilganda, pichoqning chetini shamolga qaratadi.

Strukturaviy tizimni yumshoqroq yoki moslashuvchan qilish orqali yuklarni kamaytirish mumkin.[3] Bunga shamolning rotorlari yoki shamolning yuqori tezligida hujum qilish burchagini kamaytirish uchun tabiiy ravishda aylanadigan kavisli pichoqlar bilan erishish mumkin. Ushbu tizimlar chiziqli bo'lmaydi va strukturani oqim maydoniga qo'shib qo'yadi, shuning uchun ushbu chiziqli bo'lmaganlarni modellashtirish uchun dizayn vositalari rivojlanishi kerak.

Standart zamonaviy turbinalar hammasi kuchli shamollarda pichoqlarni burishtiradi. Furling pichoq ustidagi momentga qarshi harakat qilishni talab qiladiganligi sababli, burchak burchagini boshqarishning biron bir shakli talab qilinadi, siltash haydovchi. Ushbu qo'zg'alish moslamasi pichoqni aniq burchakka burab, yuqori tork yuklariga bardosh beradi. Bundan tashqari, ko'plab turbinalarda gidravlik tizimlar qo'llaniladi. Ushbu tizimlar odatda kamon bilan o'rnatiladi, shuning uchun agar gidravlik quvvati uzilib qolsa, pichoqlar avtomatik ravishda burishadi. Boshqa turbinalarda har bir rotor pichog'i uchun elektr servomotor ishlatiladi. Elektr tarmoqlari ishdan chiqqan taqdirda ular kichik akkumulyator zaxirasiga ega. Kichik shamol turbinalari (50 kVt dan kam) o'zgaruvchanpitching umuman markazdan qochiruvchi kuch yordamida boshqariladigan tizimlarni flyweights yoki geometrik dizayni bilan ishlating va elektr yoki gidravlik boshqaruvni ishlatmang.

Universitetlar, sanoat va hukumat tadqiqotchilari koalitsiyasining hisobotida aytilishicha, energiya sarfini kamaytirishni cheklovchi pitch nazoratida asosiy bo'shliqlar mavjud. Barqaror kelajak uchun Atkinson markazi. Hozirgi vaqtda yukni qisqartirish pichoqning balandligini to'liq boshqarishga qaratilgan, chunki baland ovozli motorlar tijorat turbinalarida mavjud bo'lgan aktuator hisoblanadi. Yuklarni sezilarli darajada yumshatish pichoqlar, minora va haydovchi poezdlar uchun simulyatsiyalarda namoyish etildi. Shu bilan birga, hali ham izlanishlar kerak, energiya sarfini ko'paytirish va charchoq yuklarini yumshatish uchun pichoqning balandligini to'liq boshqarish usullarini ishlab chiqish kerak.

Qatlam burchagiga qo'llaniladigan boshqarish texnikasi dvigatelning joriy faol quvvatini nominal dvigatel tezligidagi faol quvvat qiymati bilan solishtirish orqali amalga oshiriladi (faol quvvat moslamasi, Ps mos yozuvlar). Bu holda balandlik burchagini boshqarish PI tekshiruvi elementlari yordamida amalga oshiriladi. Biroq, balandlik burchagini boshqarish tizimiga aniq javob berish uchun, aktuator vaqt o'zgaruvchisi Tservo, integralator va cheklovchilarni ishlatadi, shuning uchun balandlik burchagi o'zgarish darajasi (± ±) dan 30 ° gacha bo'lishi kerak (±) Sekundiga 10 °).

O'ngdagi rasmdan mos yozuvlar balandligi burchagi haqiqiy burchak burchagi b bilan taqqoslanadi va keyin xato aktuator tomonidan tuzatiladi. PI tekshirgichidan keladigan mos yozuvlar balandligi burchagi cheklovchidan o'tadi. Cheklovlarni cheklash real vaqtda burchak burchagini ushlab turish uchun juda muhimdir. O'zgarish tezligini cheklash, ayniqsa tarmoqdagi nosozliklar paytida juda muhimdir. Muhimligi shundaki, tekshirgich xatolar paytida tezlashishni oldini olish uchun aerodinamik energiyani qanchalik tez kamaytirishi mumkinligini hal qiladi.[3]

Boshqa boshqaruv elementlari

Jeneratör momenti

Zamonaviy yirik shamol turbinalari o'zgaruvchan tezlikda ishlaydigan mashinalardir. Shamol tezligi nominaldan past bo'lsa, iloji boricha ko'proq quvvat olish uchun rotor tezligini boshqarish uchun generator momenti ishlatiladi. Eng katta kuch qo'lga kiritilganda uchi tezligi nisbati tegmaslik qiymatida doimiy ravishda ushlab turiladi (odatda 6 yoki 7). Bu shuni anglatadiki, shamol tezligi oshganda, rotor tezligi mutanosib ravishda oshishi kerak. Pichoqlar ushlagan aerodinamik moment va qo'llaniladigan generator moment o'rtasidagi farq rotor tezligini boshqaradi. Agar generatorning momenti pastroq bo'lsa, rotor tezlashadi va generatorning momenti katta bo'lsa, rotor sekinlashadi. Shamolning nominal tezligidan past bo'lganida, generatorning momentini boshqarish faol bo'ladi, pichoq balandligi odatda shamolga etarlicha to'g'ri keladigan eng katta quvvatni ushlab turadigan doimiy burchak ostida ushlab turiladi. Nominal shamol tezligidan yuqoriroq, pichoq balandligi faol bo'lganda generator momenti doimiy ravishda ushlab turiladi.

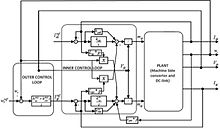

Doimiy magnitlangan sinxron motorni boshqarish usullaridan biri Dala yo'naltirilgan boshqarish. Maydonga yo'naltirilgan boshqarish - bu momentni boshqarish uchun zarur bo'lgan ikkita oqim regulyatoridan (ichki pastadir va tashqi tsikl kaskad dizayni) va bitta tezlikni boshqaruvchidan iborat yopiq halqa strategiyasi.

Doimiy moment burchagi nazorati

Ushbu boshqaruv strategiyasida d o'qi oqimi nolga teng tutiladi, vektor oqimi esa q o'qiga to'g'ri keladi va burilish burchagi 90 ga teng bo'ladi.o. Bu soddaligi sababli, faqat Iqs oqimini boshqarish orqali eng ko'p ishlatiladigan boshqaruv strategiyasidir. Shunday qilib, endi doimiy magnitlangan sinxron generatorning elektromagnit moment tenglamasi shunchaki chiziqli tenglama faqat Iqs oqimiga bog'liq.

Shunday qilib, Ids = 0 uchun elektromagnit moment (d o'qi boshqaruvchisi yordamida bunga erishishimiz mumkin):

Te= 3/2 p (λpm Menqs + (Lds-Lqs) Mends Menqs ) = 3/2 p λpm Menqs

Shunday qilib, mashina tomonidagi konvertorning to'liq tizimi va kaskadli PI tekshiruvi ko'chadanlari o'ngdagi rasm bilan berilgan. Bunda biz boshqaruvchi ma'lumotlarga egamiz, ular vazifa ratsionlari mds va mqs, PWM tomonidan boshqariladigan konvertor. Shuningdek, biz shamol turbinasini boshqarish sxemasini mashina tomonida va bir vaqtning o'zida I ni qanday saqlashimizni ko'rishimiz mumkinds nol (elektromagnit moment tenglamasi chiziqli).

Yawing

Zamonaviy yirik shamol turbinalari odatda a tomonidan o'lchangan shamol yo'nalishiga qarshi faol ravishda boshqariladi shamol pervanesi orqa tomonida joylashgan nacelle. Yaw burchagini minimallashtirish orqali (shamol va turbinani yo'naltirish yo'nalishi o'rtasidagi kelishmovchilik), quvvat quvvati maksimal darajaga ko'tariladi va nosimmetrik bo'lmagan yuklarni minimallashtiradi. Biroq, shamol yo'nalishi tez o'zgarib turadiganligi sababli, turbin yo'nalishga qat'iy rioya qilmaydi va o'rtacha yawlanish burchagiga ega bo'ladi. Elektr quvvati yo'qotishlarini (cos (yaw burchak))3. Xususan, shamolning past va o'rta tezligida esish turbinaning chiqishini sezilarli darajada kamaytirishi mumkin, shamol yo'nalishi o'zgarishi ± 30 ° ga teng bo'lib, turbinalarning shamol yo'nalishi o'zgarishiga uzoq vaqt javob beradi. Yuqori shamol tezligida shamol yo'nalishi kamroq o'zgaruvchan bo'ladi.

Elektr tormozlanishi

Kichik shamol turbinasini tormozlash generatordan energiyani a ga tashlash orqali amalga oshirilishi mumkin qarshilik turbina aylanishining kinetik energiyasini issiqlikka aylantiruvchi bank. Ushbu usul generatorga kinetik yuk birdan kamaytirilsa yoki turbinaning tezligini ruxsat etilgan chegarasida ushlab turish uchun juda kichik bo'lsa foydali bo'ladi.

Tsiklli tormozlash pichoqlarning sekinlashishiga olib keladi, bu esa to'xtash effektini oshiradi va pichoqlar samaradorligini pasaytiradi. Shunday qilib, turbinaning aylanishi tezroq shamollarda xavfsiz tezlikda ushlab turilishi mumkin (quvvat nominal). Ushbu usul odatda katta tarmoqqa ulangan shamol turbinalarida qo'llanilmaydi.

Mexanik tormozlash

Mexanik barabanli tormoz yoki disk tormozi favqulodda vaziyatlarda turbinani to'xtatish uchun ishlatiladi, masalan, haddan tashqari shamol yoki tezlikni oshirishi. Ushbu tormoz, turbinani parvarishlash uchun dam olishda ushlab turadigan ikkinchi darajali vosita bo'lib, rotorni qulflash tizimi asosiy vosita hisoblanadi. Bunday tormozlar, odatda, faqat pichoqni burishidan va elektromagnit tormozlash turbinaning tezligini pasaytirgandan keyingina qo'llaniladi, chunki mexanik tormozlar turbinani to'liq tezlikda to'xtatish uchun ishlatilsa, natsel ichida olov hosil qilishi mumkin. Tormoz RPM nominalida bosilsa turbinadagi yuk ortadi.

Turbinaning kattaligi

Shamol turbinalarining turli o'lchamdagi sinflari mavjud. 10 kVt dan kam quvvat ishlab chiqaradigan eng kichik energiya uylarda, fermer xo'jaliklarida va masofaviy dasturlarda ishlatiladi, oraliq shamol turbinalari (10-250 kVt) qishloq elektr energiyasi uchun foydalidir, gibrid tizimlar va taqsimlangan kuch. Dunyodagi eng katta shamol turbinasi, Burbo Bank Extension shamol stansiyasida joylashgan 8 MVt quvvatli turbin Liverpul ko'rfazi, Birlashgan Qirollik, 2016 yilda o'rnatilgan.[8] Markaziy stansiyada foydali turbinalar (bir megavattdan kattaroq) ishlatiladi shamol stansiyalari, taqsimlangan kuch va jamoat shamoli.[9]

Olingan shamolning tezligi uchun turbinaning massasi pichoq uzunligining kubiga taxminan mutanosibdir. Turbinani ushlab turadigan shamol kuchi uning pichog'i uzunligining kvadratiga mutanosibdir.[10] Turbinaning maksimal pichoq uzunligi ham mustahkamligi, ham materialining qattiqligi va transport jihatlari bilan cheklanadi.

Mehnat va texnik xizmat ko'rsatish xarajatlari turbinalarning kattalashishi bilan asta-sekin o'sib boradi, shuning uchun xarajatlarni minimallashtirish uchun shamol elektr stansiyalari asosan materiallarning mustahkamligi va joylashish talablari bilan cheklanadi.

Odatda zamonaviy shamol turbinalari diametri 40 dan 90 metrgacha (130 dan 300 futgacha) va 500 kVt dan 2 MVt gacha quvvatga ega. 2017 yilga kelib eng kuchli turbin Vestas V-164, 9,5 MVt quvvatga ega va rotor diametri 164 m.[11]

Borgan sari katta shamol turbinalari ishlab chiqilmoqda, ishlab chiqaruvchilar hali maksimal hajmga yaqinlashmagan. Eng katta turbinalar 265 metr va undan ko'proq bo'ladi.[12]

Nacelle

The nacelle bu uy-joy minora va rotorni bog'laydigan vites qutisi va generator. Datchiklar shamol tezligi va yo'nalishini aniqlaydi, va motorlar chiqishni maksimal darajada oshirish uchun nacelni shamolga aylantiradi.

Vites qutisi

An'anaviy shamol turbinalarida pichoqlar vites qutisi orqali generatorga ulangan o'qni aylantiradi. Vites qutisi katta, bir megavattli turbinaning pichoqlarini daqiqada 15 dan 20 gacha aylanish tezligini generatorning elektr energiyasini ishlab chiqarishi uchun zarur bo'lgan tezroq 1800 aylanishiga aylantiradi.[13] GlobalData tahlilchilarining fikriga ko'ra, vites qutisi bozori 2006 yilda 3,2 milliard dollardan 2011 yilda 6,9 milliard dollarga, 2020 yilga kelib 8,1 milliard dollarga o'sadi. Winergy 2011 yilda.[14] Magnit uzatmalar qutisidan foydalanish, shuningdek, shamol turbinasiga texnik xizmat ko'rsatish xarajatlarini kamaytirish usuli sifatida o'rganilgan.[15]

Generator

Katta, tijorat hajmi gorizontal o'qli shamol turbinalari uchun elektr generatori[16] a ga o'rnatiladi nacelle minora tepasida, turbinali rotor markazining orqasida. Odatda shamol turbinalari elektr energiyasini ishlab chiqaradi asenkron mashinalar to'g'ridan-to'g'ri elektr tarmog'i bilan bog'liq bo'lgan. Odatda shamol turbinasining aylanish tezligi elektr tarmog'ining ekvivalent aylanish tezligidan sekinroq bo'ladi: shamol generatorlari uchun odatiy aylanish tezligi 5-20 rpm, to'g'ridan-to'g'ri ulangan mashina 750 dan 3600 rpm gacha elektr tezligiga ega bo'ladi. Shuning uchun, rotor uyasi va generator o'rtasida tishli quti o'rnatilgan. Bu shuningdek, generatorning narxini va og'irligini pasaytiradi. Tijorat kattaligi generatorlari rotorga aylanuvchi qilib maydonni o'rashni olib boradi magnit maydon sarlavha to'plami ichida ishlab chiqariladi stator. Aylanadigan maydon sargisi generator ishlab chiqarish foizining bir qismini iste'mol qilsa, maydon oqimini sozlash generatorning chiqish voltajini yaxshi boshqarish imkonini beradi.

Qadimgi uslubdagi shamol generatorlari mos keladigan tezlikda aylanadi elektr uzatish liniyasining chastotasi, bu esa arzonroq induksion generatorlardan foydalanishga imkon berdi.[iqtibos kerak ] Yangi shamol turbinalari ko'pincha elektr energiyasini ishlab chiqaradigan har qanday tezlikda aylanadi. Turli xil chiqish chastotasi va kuchlanish kabi bir nechta texnologiyalar yordamida tarmoqning belgilangan qiymatlariga mos kelishi mumkin ikki marta oziqlanadigan indüksiyon generatorlari yoki ishlab chiqarilgan o'zgaruvchan chastotali oqim doimiy ravishda o'zgarib turadigan va keyin o'zgaruvchan tokga aylanadigan to'liq effektli konvertorlar. Garchi bunday alternativalar qimmatbaho uskunalarni talab qilsa va elektr energiyasini yo'qotishiga olib kelsa-da, turbin shamol energiyasining sezilarli darajada katta qismini egallashi mumkin. Ba'zi hollarda, ayniqsa, turbinalar dengizga joylashtirilganda, doimiy energiya turbinadan markaziy (quruqlikka) uzatiladi. inverter tarmoqqa ulanish uchun.

Gearless turbinasi

Gearless shamol turbinalari (shuningdek, deyiladi) to'g'ridan-to'g'ri haydovchi ) vites qutisini butunlay olib tashlang. Buning o'rniga, rotor o'qi to'g'ridan-to'g'ri generatorga biriktirilgan bo'lib, u pichoqlar bilan bir xil tezlikda aylanadi.

PMDD generatorlarining afzalliklari Vitesga asoslangan generatorlar samaradorlikni oshirishni, shovqinni pasayishini, uzoq umr ko'rishni, past aylanish / min. yuqori momentni, tezroq va aniq joylashishni va qo'zg'alishning qattiqligini o'z ichiga oladi. PMDD generatorlari "tishli tezlikni oshiruvchi vositani yo'q qiladi, bu charchash momentini sezilarli darajada to'planishiga, tegishli ishonchlilik masalalariga va texnik xarajatlarga ta'sir qiladi."[17]

To'g'ridan-to'g'ri qo'zg'aysan generatorining tezroq aylanish tezligini, generatorning diametrini qoplash uchun rotor kerakli chastota va quvvatni yaratish uchun ko'proq magnitlarni o'z ichiga olishi uchun ko'paytiriladi. Gearless shamol turbinalari ko'pincha tishli shamol turbinalaridan og'irroq. Tomonidan olib borilgan tadqiqotlar EI "Reliawind" deb nomlangan[18] turbinalarning eng katta namunaviy hajmiga asoslanib, vites qutilarining ishonchliligi shamol turbinalarida asosiy muammo emasligini ko'rsatdi. To'g'ridan-to'g'ri qo'zg'aysan turbinalarining dengizdagi ishonchliligi hali ham ma'lum emas, chunki namuna hajmi juda kichik.

Mutaxassislar Daniya Texnik universiteti doimiy magnitlangan uzatma generatorining 25 kg / MVt dan foydalanishi mumkinligini taxmin qiling noyob tuproq elementi Neodimiy, reduktorsiz esa 250 kg / MVt ishlatishi mumkin.[19]

2011 yil dekabr oyida AQSh Energetika vazirligi tishli shamol turbinalarida doimiy magnit uchun katta miqdorda ishlatiladigan neodimiy kabi noyob tuproq elementlarining tanqisligi to'g'risida hisobot e'lon qildi.[20] Xitoy noyob elementlarning 95 foizidan ko'prog'ini ishlab chiqaradi, shu bilan birga Xitachi 600 dan ortiq patentga ega Neodimiy magnitlari.Birgalikda boshqariladigan turbinalar uchun har bir megavatt uchun 600 kg doimiy magnit material kerak bo'ladi, bu megavatt uchun bir necha yuz kilogramm kamyob tuproq tarkibiga to'g'ri keladi, chunki neodimiy miqdori magnit og'irligining 31 foizini tashkil qiladi. Gibrid haydovchi dvigatellar (to'g'ridan-to'g'ri qo'zg'aysan va an'anaviy uzatmalar o'rtasida) kamdan-kam uchraydigan tuproqli materiallardan foydalanadilar, doimiy magnitlangan shamol turbinalari Xitoy tashqarisidagi bozorning atigi 5 foizini tashkil qilar ekan, ularning Xitoydagi bozordagi ulushi 25 foiz va undan yuqori .2011 yilda shamol turbinalarida neodimiyaga bo'lgan talab elektr transport vositalarining 1/5 qismiga teng deb baholandi.[20]

Pichoqlar

Pichoq dizayni

Ning tezligi orasidagi nisbat pichoq uchlari va shamolning tezligi deyiladi uchi tezligi nisbati. Yuqori samarali 3-pichoqli turbinalar uchi tezligi / shamol tezligi nisbati 6 dan 7 gacha. Zamonaviy shamol turbinalari har xil tezlikda aylanish uchun mo'ljallangan (ularning generatori dizayni natijasida, yuqoriga qarang). Dan foydalanish alyuminiy va kompozit materiallar ularning pichoqlarida past darajadagi hissa qo'shgan aylanma harakatsizlik Bu shuni anglatadiki, agar shamol ko'tarilsa, yangi turbinalar tezda tezlashishi mumkin va uchi tezligini deyarli doimiy ravishda ushlab turadi. Baquvvat shamol paytida ularning optimal uchish tezligiga nisbati yaqinroq ishlash shamol turbinalariga shahar sharoitida odatiy bo'lgan to'satdan kuchli shamollardan energiya olishni yaxshilaydi.

Aksincha, eski uslubdagi shamol turbinalari og'irroq po'lat pichoqlar bilan ishlangan bo'lib, ular yuqori inertsiyaga ega va elektr uzatish liniyalarining o'zgaruvchan chastotasi bilan boshqariladigan tezlikda aylantirilgan. Yuqori inertsiya aylanish tezligidagi o'zgarishlarga to'sqinlik qildi va shu bilan quvvat chiqishini barqaror qildi.

Odatda, pichoq uchi tezligi oshganda shovqin kuchayishi tushuniladi. Shovqinni oshirmasdan uchi tezligini oshirish vites qutisi va generatorga aylanish momentini kamaytirishga va umumiy konstruktiv yuklarni kamaytirishga imkon beradi va shu bilan narxni pasaytiradi.[3]Shovqinning pasayishi pichoqlarning batafsil aerodinamikasi bilan, ayniqsa to'satdan to'xtashni kamaytiradigan omillar bilan bog'liq. To'xtashni bashorat qilishning iloji yo'qligi agressiv aerodinamik tushunchalarning rivojlanishini cheklaydi.[3] Ba'zi pichoqlar (asosan Enercon-da) a ga ega qanotli qanot ishlashni oshirish va shovqinni kamaytirish uchun.[21][22]

Pichoqda a bo'lishi mumkin tortish-tortish nisbati 120 dan,[23] a uchun 70 ga nisbatan yelkanli samolyot va 15 samolyot uchun.[24]

Markaz

Oddiy konstruktsiyalarda pichoqlar to'g'ridan-to'g'ri uyaga bog'langan va balandlikni ko'tarolmaydilar, bu esa ma'lum shamol tezligi ustidagi aerodinamik to'xtashga olib keladi. Boshqa murakkab dizaynlarda ular mahkamlangan pitch rulmani, bu ularni moslashtiradi hujum burchagi ularning aylanish tezligini boshqarish uchun shamol tezligiga qarab balandlik tizimi yordamida.[25] Pitchni boshqarish gidravlik yoki elektr tizimlari tomonidan amalga oshiriladi (qo'rg'oshin-kislotali akkumulyator yoki ultra kondansatör ).[26] Qatlamli podshipnikning o'zi markazga mahkamlangan. Hub generatorni to'g'ridan-to'g'ri yoki uzatmalar qutisi orqali boshqaradigan rotor miliga o'rnatiladi.

Pichoqni hisoblash

Ushbu bo'lim a ni o'z ichiga oladi foydalanilgan adabiyotlar ro'yxati, tegishli o'qish yoki tashqi havolalar, ammo uning manbalari noma'lum bo'lib qolmoqda, chunki u etishmayapti satrda keltirilgan. (2012 yil avgust) (Ushbu shablon xabarini qanday va qachon olib tashlashni bilib oling) |

Pichoqlar soni aerodinamik samaradorlik, komponentlarning narxi va tizimning ishonchliligi uchun tanlanadi. Shovqin chiqindilariga pichoqlarning minoradan yuqoriga yoki pastga qarab joylashishi va rotorning tezligi ta'sir qiladi. Pichoqlarning orqadagi chekkalari va uchlaridan chiqadigan shovqinlar pichoq tezligining 5-kuchiga qarab o'zgarib turishini hisobga olsak, uchi tezligining ozgina oshishi katta farq qilishi mumkin.

So'nggi 50 yil ichida ishlab chiqarilgan shamol turbinalari deyarli ikki yoki uchta pichoqni universal ravishda ishlatgan. Shu bilan birga, Chan Shinning Multi-unit rotor pichoqli tizimiga o'rnatilgan shamol turbinasi kabi qo'shimcha pichoqlar bilan dizaynlashtirilgan patentlar mavjud.[27]Aerodinamik samaradorlik pichoqlar soniga qarab ortadi, lekin qaytish kamayadi. Pichoqlar sonini birdan ikkitaga oshirish aerodinamik samaradorlikni olti foizga ko'paytiradi, pichoq sonini ikkitadan uchgacha oshirish samaradorlikning qo'shimcha uch foizini beradi.[28] Pichoqlar sonini yanada oshirish aerodinamik samaradorlikni minimal darajada yaxshilaydi va pichoqlar qattiqlashganda juda ko'p qurbonliklar beradi, chunki pichoqlar ingichka bo'ladi.[iqtibos kerak ]

Nazariy jihatdan, nol kenglikdagi cheksiz ko'p pichoqlar eng samarali hisoblanadi, uchi tezligi nisbati yuqori qiymatida ishlaydi. Ammo boshqa fikrlar bir nechta pichoqlarning kelishuviga olib keladi.[29]

Pichoqlar soniga ta'sir qiluvchi komponent xarajatlari, birinchi navbatda, turbinali rotor va qo'zg'aysan poezdining materiallari va ishlab chiqarishiga bog'liq. Odatda, pichoqlar soni qancha kam bo'lsa, material va ishlab chiqarish xarajatlari shunchalik past bo'ladi. Bunga qo'shimcha ravishda, pichoqlar soni qancha kam bo'lsa, aylanish tezligi shunchalik yuqori bo'lishi mumkin. Buning sababi shundaki, pichoqning qattiqligi talablari minora bilan to'sqinlik qilmaslik uchun pichoqlarni ishlab chiqarishning qanchalik nozikligini cheklaydi, lekin faqat shamol shamol mashinalari uchun; pichoqlarni pastga yo'naltirilgan mashinada burish minora tozaligini oshirishga olib keladi. Aylanish tezligi yuqori bo'lgan kamroq pichoqlar qo'zg'aysan poezdidagi eng yuqori momentlarni kamaytiradi, natijada vites qutisi va generator xarajatlari past bo'ladi.

Tizimning ishonchliligi, birinchi navbatda, rotorni harakatlantiruvchi poezd va minora tizimlariga dinamik ravishda yuklash orqali pichoqlar soniga ta'sir qiladi. Shamol turbinasini shamol yo'nalishi o'zgarishiga moslashtirganda (yawing), har bir pichoq pichoq holatiga qarab ildiz uchida tsiklik yukni boshdan kechiradi. Bu bitta, ikki, uchta pichoq yoki undan ko'pida to'g'ri keladi. Shu bilan birga, ushbu tsikl yuklari qo'zg'aysan poyezdi shaftida birlashtirilib, uchta pichoq uchun nosimmetrik tarzda muvozanatlanadi va turbinani yawlash paytida yumshoq ishlaydi. Bir yoki ikkita pichoqli turbinalar burilish moslamali markazdan foydalanishi mumkin, shuningdek eskirish paytida qo'zg'aysan valiga va tizimiga tsiklik yuklarni deyarli yo'q qiladi. Daniyada Xitoyning 3,6 MVt quvvatli ikki pichog'i sinovdan o'tkazilmoqda.[30] Mingyan 2013 yilda Chjuxay yaqinidagi 87 MVt (29 * 3 MVt) ikki qanotli dengiz shamol turbinalari uchun taklifni qo'lga kiritdi.[31][32][33]

Va nihoyat, estetikani ba'zi odamlar uchta pichoqli rotorni bir yoki ikki pichoqli rotorga qaraganda yoqimli deb biladigan omil deb hisoblashlari mumkin.

Pichoq materiallari

Umuman olganda, ideal materiallar quyidagi mezonlarga javob berishi kerak:

- xarajatlarni kamaytirish va texnik xizmat ko'rsatishni kamaytirish uchun keng foydalanish va oson ishlov berish

- tortish kuchlarini kamaytirish uchun kam og'irlik yoki zichlik

- shamolning kuchli yuklanishiga va pichoqning o'ziga tortish kuchiga qarshi turish uchun yuqori quvvat

- tsiklik yuklashga bardosh berish uchun yuqori charchoq qarshilik

- pichoqning optimal shakli va yo'nalishi barqarorligini va minora bilan bo'shliqni ta'minlash uchun yuqori qattiqlik

- yuqori singanlik

- chaqmoq urishi, namlik va harorat kabi atrof-muhit ta'siriga qarshi turish qobiliyati[34]

Bu maqbul materiallar ro'yxatini qisqartiradi. Metall charchoqqa nisbatan zaifligi sababli istalmagan bo'lar edi. Seramika singanligi past bo'lgan, bu esa pichoqning erta ishdan chiqishiga olib kelishi mumkin. An'anaviy polimerlar foydali bo'lishi uchun etarlicha qattiq emas va yog'och, ayniqsa pichoqning uzunligini hisobga olgan holda takrorlanadigan muammolarga duch keladi. Shunday qilib, shamol turbinalarini loyihalash uchun juda jozibali materiallar sinfi sifatida yuqori mustahkamlik va qattiqlik va zichlikka ega bo'lgan tola bilan mustahkamlangan kompozitsiyalar qoladi.[35]

Yog'och va kanvasdan yasalgan suzib yurishlar arzonligi, mavjudligi va ishlab chiqarish qulayligi tufayli dastlabki shamol tegirmonlarida ishlatilgan. Kichik pichoqlar kabi engil metallardan tayyorlanishi mumkin alyuminiy. Biroq, ushbu materiallar tez-tez parvarish qilishni talab qiladi. Yog'och va kanvas qurilishi chegaralarni cheklaydi plyonka qattiq tekislik bilan taqqoslaganda tortishish kuchini tortib olish kuchi (past aerodinamik samaradorlik) nisbatan yuqori nisbati bo'lgan tekis plastinka shakli. Qattiq plyonkali konstruktsiyalarni qurish uchun egiluvchan materiallar, masalan, metall yoki kompozitsiyalar. Ba'zi pichoqlarda chaqmoq o'tkazgichlari ham mavjud.

Shamol turbinasining yangi konstruktsiyalari elektr energiyasini ishlab chiqarishni yakka tartibda kuchaytiradi megavatt kattaroq va kattaroq pichoqlar yordamida 10 megavattdan yuqoriga ko'tariladi. Kattaroq maydon turbinaning uchish tezligini ma'lum bir shamol tezligida samarali ravishda oshiradi va shu bilan uning energiya chiqarilishini oshiradi.[36]Kompyuter texnikasi kabi dasturiy ta'minot HyperSizer (dastlab kosmik kemalarni loyihalash uchun ishlab chiqilgan) pichoq dizaynini yaxshilash uchun ishlatilishi mumkin.[37][38]

2015 yil holatiga ko'ra quruqlikdagi shamol turbinasi pichoqlarining aylanish diametri 130 metrga teng,[39] dengiz turbinalarining diametri esa 170 metrga etadi.[40] 2001 yilda taxminan 50 million kilogramm shisha tola laminat shamol turbinasi pichoqlarida ishlatilgan.[41]

Kattaroq pichoq tizimlarining muhim maqsadi pichoqning og'irligini boshqarishdir. Pichoq massasi turbin radiusining kubi sifatida tortilganligi sababli tortishish tufayli yuklanish katta pichoqli tizimlarni cheklaydi.[42] Gravitatsiyaviy yuklarga eksenel va tortish / siqish yuklari (aylanishning yuqori / pastki qismlari), shuningdek egilish (lateral pozitsiyalar) kiradi. Ushbu yuklarning kattaligi davriy ravishda o'zgarib turadi va qarama-qarshi momentlar (pastga qarang) har 180 ° burilishda o'zgaradi, odatdagi rotor tezligi va dizayn muddati mos ravishda ~ 10 va 20 yil, umr bo'yi aylanishlar soni 10 ^ tartibda. 8. Shamolni hisobga olgan holda, turbinalar pichoqlari ~ 10 ^ 9 yuklash davrlarini o'tashi kutilmoqda, shamol rotor pichog'ini yuklashning yana bir manbai. Ko'tarish tekis yo'nalishda (rotor tekisligidan) egilishga, pichoq atrofidagi havo oqimi esa (rotor tekisligida) egilishga olib keladi. Qopqoqlarning egilishi bosim (yuqoriga) tomonga taranglikni va assimilyatsiya (pastga) tomondan siqishni o'z ichiga oladi. Edgewise egiluvchanligi oldingi chekkada taranglikni va orqadagi chekkada siqishni o'z ichiga oladi.

Shamolning tezligi va shamolning qaynashidagi tabiiy o'zgaruvchanlik (aylanishning yuqori qismida yuqori tezlik) tufayli shamol yuklari tsiklikdir.

Shamolga va tortishish kuchiga ta'sir qiladigan shamol turbinasi rotor pichoqlarini oxirigacha yuklashdagi nosozlik, bu rotor pichoqlari ishlab chiqilganda e'tiborga olinishi kerak bo'lgan ishlamay qolish rejimidir. Rotor pichoqlarining egilishiga olib keladigan shamol tezligi tabiiy o'zgaruvchanlikni namoyish etadi va rotor pichoqlaridagi stress ta'siriga ham ta'sir qiladi. Shuningdek, rotor pichoqlarining qarshiligi, ularning tortishish kuchi jihatidan tabiiy o'zgaruvchanlikni namoyish etadi.[43]

Ushbu nosozlik rejimlari va tobora kattalashib borayotgan pichoq tizimlari asosida, yuqori massaga nisbati yuqori bo'lgan iqtisodiy jihatdan samarali materiallarni ishlab chiqarish bo'yicha doimiy harakatlar olib borildi. Hozirgi 20 yillik pichoqlarning ishlash muddatini uzaytirish va kattaroq maydon pichoqlarini tejamkor bo'lishiga imkon berish uchun dizayn va materiallarni qattiqlik, kuch va charchoqqa chidamliligi uchun optimallashtirish kerak.[34]

Hozirgi tijoratlashtirilgan shamol turbinasi pichoqlarining aksariyati polimer matritsasi va tolalaridan tashkil topgan kompozitlar bo'lgan tolalar bilan mustahkamlangan polimerlardan (FRP) ishlab chiqarilgan. Uzoq tolalar uzunlamasına qattiqlik va mustahkamlikni ta'minlaydi va matritsa singanlarning chidamliligini, delaminatsiya kuchini, tekislikdan tashqari mustahkamlikni va qattiqlikni ta'minlaydi.[34] Energiya samaradorligini maksimal darajada oshirishga asoslangan materiallar va yuqori sinishga chidamliligi, charchoqqa chidamliligi va issiqlik barqarorligiga ega bo'lgan shisha va uglerod tolasi bilan mustahkamlangan plastmassalar (GFRP va CFRP) uchun eng yuqori ko'rsatkichlar ko'rsatilgan.[44]

Turbinali pichoqlarda termoset yoki termoplastik kabi matritsalardan foydalaniladi, birinchisi tez-tez uchraydi [45]. Bular tolalarni bir-biriga bog'lashga imkon beradi va pichoqqa qattiqlik qo'shadi. Termosetlar bozorning 80% ni tashkil qiladi, chunki ular past haroratni davolashga imkon beradi, va yopishqoqligi past bo'lib, oson ishlov berish uchun birlashtiriladi. Termoplastiklar qayta ishlashga imkon beradi, ular termosetlarda yo'q, shu bilan birga ishlov berish harorati va yopishqoqligi ancha yuqori bo'lib, katta pichoqlar uchun muhim bo'lgan o'lcham va zichlikni cheklaydi. Singanning chidamliligi termoplastikada yuqori, ammo charchoq harakati yomonroq [46]. Termoplastikalar ekologik jihatdan afzalliklarga ega bo'lishiga qaramay, ko'proq tadqiqotlar o'tkazish kerak.

40 dan 50 metrgacha bo'lgan pichoqlarni ishlab chiqarish tasdiqlangan shisha tolali kompozit ishlab chiqarish texnikasini o'z ichiga oladi. Kabi ishlab chiqarishlar Nordex SE va GE Shamol infuzion jarayondan foydalaning. Boshqa ishlab chiqaruvchilar ushbu texnikada o'zgarishlarni qo'llaydilar, ba'zilari ham shu jumladan uglerod va yog'och shisha tolali shisha bilan epoksi matritsa. Boshqa variantlarga oldindan singdirilgan ("prepreg") shisha tolali va vakuum yordamida qatronlar o'tkazadigan kalıplama kiradi. Ushbu variantlarning har biri mustahkamlangan shisha tolalardan foydalaniladi polimer turli xil murakkablik bilan qurilgan kompozit. Ehtimol, soddalashtirilgan, ochiq qolipli va ho'l tizimlar bilan bog'liq eng katta muammo bu uchuvchi organik moddalar bilan bog'liq chiqindilar. Oldindan emdirilgan materiallar va qatronlar bilan quyish texnikasi barcha VOClarni o'z ichiga olgan holda uchuvchi moddalarning tarqalishini oldini oladi. Biroq, ushbu tarkibdagi jarayonlarning qiyinchiliklari bor, ya'ni tarkibiy qismlar uchun zarur bo'lgan qalin laminat ishlab chiqarish qiyinlashadi. Preform qatronlar o'tkazuvchanligi maksimal laminat qalinligini belgilab qo'yganligi sababli, bo'shliqlarni yo'q qilish va qatronlarning to'g'ri taqsimlanishini ta'minlash uchun qon ketish kerak.[41]Qatronlarni taqsimlash uchun bitta echim qisman singdirilgan shisha tolalarni. Evakuatsiya paytida quruq mato havo oqimi uchun yo'lni ta'minlaydi va issiqlik va bosim qo'llanilgandan so'ng, qatron quruq mintaqaga oqib tushishi mumkin, natijada yaxshilab singdirilgan laminat tuzilishga olib keladi.[41]

Epoksi asosidagi kompozitlar boshqa qatronlar tizimlariga nisbatan ekologik, ishlab chiqarish va iqtisodiy afzalliklarga ega. Epoxies also allow shorter cure cycles, increased durability, and improved surface finish. Prepreg operations further reduce processing time over wet lay-up systems. As turbine blades pass 60 metres, infusion techniques become more prevalent; the traditional resin transfer moulding injection time is too long as compared to the resin set-up time, limiting laminate thickness. Injection forces resin through a thicker ply stack, thus depositing the resin wherein the laminate structure before gelation occurs. Specialized epoxy resins have been developed to customize lifetimes and viscosity.[48]

Carbon fibre-reinforced load-bearing spars can reduce weight and increase stiffness. Using carbon fibres in 60-metre turbine blades is estimated to reduce total blade mass by 38% and decrease cost by 14% compared to 100% fibreglass. Carbon fibres have the added benefit of reducing the thickness of fibreglass laminate sections, further addressing the problems associated with resin wetting of thick lay-up sections. Wind turbines may also benefit from the general trend of increasing use and decreasing cost of carbon fibre materials.[41]

Although glass and carbon fibres have many optimal qualities for turbine blade performance, there are several downsides to these current fillers, including the fact that high filler fraction (10-70 wt%) causes increased density as well as microscopic defects and voids that often lead to premature failure.[34]

Recent developments include interest in using carbon nanotubes (CNTs) to reinforce polymer-based nanocomposites. CNTs can be grown or deposited on the fibres or added into polymer resins as a matrix for FRP structures. Using nanoscale CNTs as filler instead of traditional microscale filler (such as glass or carbon fibres) results in CNT/polymer nanocomposites, for which the properties can be changed significantly at very low filler contents (typically < 5 wt%). They have very low density and improve the elastic modulus, strength, and fracture toughness of the polymer matrix. The addition of CNTs to the matrix also reduces the propagation of interlaminar cracks which can be a problem in traditional FRPs.[34]

Current research on a low-cost carbon fiber (LCCF) at Oak Ridge National Lab has also gained attention however, as it can mitigate the structural degradation caused from lightning strikes [49]. On glass fiber wind turbines, a lightning strike protection (LSP) is usually added on top, but this is effectively deadweight in terms of structural contribution. Replacing this with conductive carbon fiber, especially as carbon fiber is a better material, would be ideal.

Another recent development from research is using polymer composites that feature self-healing properties for blade materials [50]. Self-healing polymers are attractive for this application, as the blades of the turbine form cracks from fatigue due to repetitive cyclic stresses, described above, and can thus improve reliability and act as a buffer for various defects and delamination. Thus, in this application, the polymer is used to heal the cracks as they form. Specifically, one study focuses on embedding paraffin wax-coated copper wires in a fiber reinforced polymer to create a network of tubes. Using these tubes, dicyclopentadiene (DCPD) and a catalyst, which then react to form a thermosetting polymer, which repairs the cracks that form in the material. While this is still early in the R&D process, it offers a promising development, especially for polymer networks that are prone to manufacturing defects or turbines in offshore environments that are subject to extremely high fatigue due to powerful winds.

Further improvement is possible through the use of carbon nanofibers (CNFs) in the blade coatings. A major problem in desert environments is erosion of the leading edges of blades by wind carrying sand, which increases roughness and decreases aerodynamic performance. The particle erosion resistance of fibre-reinforced polymers is poor when compared to metallic materials and elastomers, and needs to be improved. It has been shown that the replacement of glass fibre with CNF on the composite surface greatly improves erosion resistance. CNFs have also been shown to provide good electrical conductivity (important for lightning strikes), high damping ratio, and good impact-friction resistance. These properties make CNF-based nano paper a prospective coating for wind turbine blades.[51][52]

For wind turbines, especially those offshore, or in wet environments, water base surface erosion also occurs. For example, in cold climates, ice can build up on the blades and increase the roughness, decreasing the power output and lifetime of the turbine blades. Further, when the blade is spinning at high speeds, this same erosion impact can occur from rainwater. Thus, a coating that has a low installation cost and no energy consumption during its lifetime is a good solution. A coating must have the following properties: good adhesion with the blade, temperature resistance (from seasonal changes), weather resistance (to resist erosion from salt, rain, sand, etc.), good mechanical strength, ability to withstand ultraviolet light, and have anti-icing and flame retardant properties. Along with this, the coating should be cheap and environmentally friendly [53].

One current area of research on these coatings for ice/ water erosion prevention is Super hydrophobic surfaces (SHS), where water droplets bead up, and roll off the blades as it spins [54]. SHS has shown to also prevent ice formation, up to -25 C, as it has been found to change the ice formation process [55]. ; specifically, small ice islands formed on the SHS, as opposed to a large ice front. Further, due to the lowered surface area from the hydrophobic surface, the aerodynamic forces on the blade allowed these islands to glide off the blade, preventing further formation. Other strategies to combine these coatings with heating elements along the blades to further prevent ice formation are being explored, but as the industry pushes for longer blades, the energy consumption to heat the blades increases.

Another important source of degradation for turbine blades is lightning damage, which over the course of a normal 25-year lifetime is expected to experience a number of lightning strikes throughout its service.[56] The range of damage caused from lightning strikes goes from merely surface level scorching and cracking of the laminate material, to ruptures in the blade or full separation in the adhesives that hold the blade together.[56] It is most common to observe lightning strikes on the tips of the blades, especially in rainy weather due to the copper wiring within attracting lightning.[57] The most common method to combat this, especially in non-conducting blade materials like GFRPs and CFRPs, is to add lightning "arresters", which are merely metallic wiring that provides an uninterrupted path to the ground, skipping the blades and gearbox entirely to eliminate the risk of damage in those components.[57]

Blade recycling

The Global Wind Energy Council (GWEC) predicts that wind energy will supply 15.7% of the world's total energy needs by the year 2020, and 28.5% by the year 2030.[58] This dramatic increase in global wind energy generation will require installation of a newer and larger fleet of more efficient wind turbines and the consequent decommissioning of aging ones. Based on a study carried out by the European Wind Energy Association, in the year 2010 alone, between 110 and 140 kilotons of composites were consumed by the wind turbine industry for manufacturing blades.[59] The majority of the blade material will eventually end up as waste, and in order to accommodate this level of composite waste, the only option is recycling. As of 2020, most end-of-use blades are temporarily stored or sent to landfills rather than recycled.[60] Typically, glass-fibre-reinforced-polymers (GFRPs) compose of around 70% of the laminate material in the blade. GFRPs hinder incineration and are not combustible.[61] Therefore, conventional recycling methods need to be modified. Currently, depending on whether individual fibres can be recovered, there exists a few general methods for recycling GFRPs in wind turbine blades:

- Mechanical Recycling: This method doesn't recover individual fibres. Initial processes involve shredding, crushing, or milling. The crushed pieces are then separated into fibre-rich and resin-rich fractions. These fractions are ultimately incorporated into new composites either as fillers or reinforcements.[62]

- Chemical Processing/Piroliz: Thermal decomposition of the composites is used to recover the individual fibres. Uchun piroliz, the material is heated up to 500 °C in an environment without oxygen, thus causing it to break down into lower weight organic substances and gaseous products. The glass fibres will generally lose 50% of their initial strength and can now be downcycled for fibre reinforcement applications in paints or concrete.[63] Research has shown that this end of life option is able to recover up to approximately 19 MJ/kg.[61] However, this method has a relatively high cost and requires similar mechanical pre-processing. In addition, it has not yet been modified to satisfy the future need of large scale wind turbine blade recycling.[64]

- Direct Structural recycling of composites: Developed to combat the inefficiencies and costs associated with chemical, thermal and mechanical recycling processes, which either reduce the performance properties or only act as filler for other composites. The general idea to this method is to reuse the composite as is, which can be achieved especially in larger composite materials as it can be partitioned in several pieces which can be used in other applications as is, without altering the chemical properties of the composite component.[65]

One start-up, Global Fiberglass Solutions, states it has a method to break down blades and press them into pellets and fiber boards to be used for flooring and walls. The company started producing samples at a plant in Sweetwater, Texas, near the continent’s largest concentration of wind farms. It plans another operation in Iowa.[66]

Minora

Minora balandligi

Wind velocities increase at higher altitudes due to surface aerodynamic drag (by land or water surfaces) and the viscosity of the air. The variation in velocity with altitude, called shamolni kesish, is most dramatic near the surface.Typically, the variation follows the shamol profilining kuchi to'g'risidagi qonun, which predicts that wind speed rises proportionally to the seventh root of altitude. Doubling the altitude of a turbine, then, increases the expected wind speeds by 10% and the expected power by 34%. Qochish uchun buklanish, doubling the tower height generally requires doubling the diameter of the tower as well, increasing the amount of material by a factor of at least four.

At night time, or when the atmosphere becomes barqaror, wind speed close to the ground usually subsides whereas at turbine hub altitude it does not decrease that much or may even increase. As a result, the wind speed is higher and a turbine will produce more power than expected from the 1/7 power law: doubling the altitude may increase wind speed by 20% to 60%. A stable atmosphere is caused by radiative cooling of the surface and is common in a temperate climate: it usually occurs when there is a (partly) clear sky at night. When the (high altitude) wind is strong (a 10-meter wind speed higher than approximately 6 to 7 m/s) the stable atmosphere is disrupted because of friction turbulence and the atmosphere will turn neytral. A daytime atmosphere is either neutral (no net radiation; usually with strong winds and heavy clouding) or beqaror (rising air because of ground heating—by the sun). Here again the 1/7 power law applies or is at least a good approximation of the wind profile. Indiana had been rated as having a wind capacity of 30,000 MW, but by raising the expected turbine height from 50 m to 70 m, the wind capacity estimate was raised to 40,000 MW, and could be double that at 100 m.[67]

Uchun HAWTs, tower heights approximately two to three times the blade length have been found to balance material costs of the tower against better utilisation of the more expensive active components.

Road size restrictions makes transportation of towers with a diameter of more than 4.3 m difficult. Swedish analyses show that it is important to have the bottom wing tip at least 30 m above the tree tops, but a taller tower requires a larger tower diameter.[68] A 3 MW turbine may increase output from 5,000 MWh to 7,700 MWh per year by going from 80 to 125 meter tower height.[69] A tower profile made of connected shells rather than cylinders can have a larger diameter and still be transportable. A 100 m prototype tower with TC bolted 18 mm 'plank' shells has been erected at the wind turbine test center Høvsøre in Denmark and certified by Det Norske Veritas, bilan Simens nacelle. Shell elements can be shipped in standard 12 m konteynerlar,[68][70] and 2½ towers per week are produced this way.[71]

As of 2003, typical modern wind turbine installations use towers about 210 ft (65 m) high.Height is typically limited by the availability of kranlar.This has led to a variety of proposals for "partially self-erecting wind turbines" that, for a given available crane, allow taller towers that put a turbine in stronger and steadier winds, and "self-erecting wind turbines" that can be installed without cranes.[72][73][74][75]

Tower materials

Currently, the majority of wind turbines are supported by conical tubular steel towers. These towers represent 30% – 65% of the turbine weight and therefore account for a large percentage of the turbine transportation costs. The use of lighter materials in the tower could greatly reduce the overall transport and construction cost of wind turbines, however the stability must be maintained.[76]Higher grade S500 steel costs 20%-25% more than S335 steel (standard strukturaviy po'latdir ), but it requires 30% less material because of its improved strength. Therefore, replacing wind turbine towers with S500 steel would result in net savings both in weight and cost.[77]

Another disadvantage of conical steel towers is that constructing towers that meet the requirements of wind turbines taller than 90 meters proves challenging. High performance concrete shows potential to increase tower height and increase the lifetime of the towers. A hybrid of oldindan kuchlanishli beton and steel has shown improved performance over standard tubular steel at tower heights of 120 meters.[78] Concrete also gives the benefit of allowing for small precast sections to be assembled on site, avoiding the challenges steel faces during transportation.[79] One downside of concrete towers is the higher CO2 emissions during concrete production as compared to steel. However, the overall environmental benefit should be higher if concrete towers can double the wind turbine lifetime.[80]

Yog'och is being investigated as a material for wind turbine towers, and a 100 metre tall tower supporting a 1.5 MW turbine has been erected in Germany. The wood tower shares the same transportation benefits of the segmented steel shell tower, but without the steel resurslarni iste'mol qilish.[81][82]

Connection to the electric grid

All grid-connected wind turbines, from the first one in 1939 until the development of variable-speed grid-connected wind turbines in the 1970s, were fixed-speed wind turbines.As recently as 2003, nearly all grid-connected wind turbines operated at exactly constant speed (synchronous generators) or within a few percent of constant speed (induction generators).[83][84]As of 2011, many operational wind turbines used fixed speed induction generators (FSIG).[85]As of 2011, most new grid-connected wind turbines are variable speed wind turbines —they are in some variable speed configuration.[85]

Early wind turbine control systems were designed for peak power extraction, also called maximum power point tracking —they attempt to pull the maximum possible electrical power from a given wind turbine under the current wind conditions.[iqtibos kerak ]More recent wind turbine control systems deliberately pull less electrical power than they possibly could in most circumstances, in order to provide other benefits, which include:

- spinning reserves to quickly produce more power when needed—such as when some other generator suddenly drops from the grid—up to the max power supported by the current wind conditions.[iqtibos kerak ]

- Variable-speed wind turbines can (very briefly) produce more power than the current wind conditions can support, by storing some wind energy as kinetic energy (accelerating during brief gusts of faster wind) and later converting that kinetic energy to electric energy (decelerating, either when more power is needed elsewhere, or during short lulls in the wind, or both).[86][87]

- damping (electrical) subsynchronous resonances in the grid[88]

- damping (mechanical) resonances in the tower[89][90]

The generator in a wind turbine produces o'zgaruvchan tok (AC) electricity. Some turbines drive an AC / AC konvertori —which converts the AC to to'g'ridan-to'g'ri oqim (DC) with a rektifikator and then back to AC with an inverter —in order to match the frequency and phase of the grid. However, the most common method in large modern turbines is to instead use a doubly fed induction generator directly connected to the elektr tarmog'i.

A useful technique to connect a permanent magnet synchronous generator to the grid is by using a back-to-back converter. Also, we can have control schemes so as to achieve unity quvvat omili in the connection to the grid. In that way the wind turbine will not consume reactive power, which is the most common problem with wind turbines that use induction machines. This leads to a more stable power system. Moreover, with different control schemes a wind turbine with a permanent magnet synchronous generator can provide or consume reactive power. So, it can work as a dynamic capacitor /induktor bank so as to help with the power systems' stability.

Below we show the control scheme so as to achieve unity power factor :

Reaktiv quvvat regulation consists of one PI tekshiruvi in order to achieve operation with unity power factor (i.e. Qpanjara = 0 ). It is obvious that IdN has to be regulated to reach zero at steady-state (IdNref = 0).

We can see the complete system of the grid side converter and the cascaded PI controller loops in the figure in the right.

Qurilish

As wind turbine usage has increased, so have companies that assist in the planning and construction of wind turbines. Most often, turbine parts are shipped via sea or rail, and then via truck to the installation site. Due to the massive size of the components involved, companies usually need to obtain transportation permits and ensure that the chosen trucking route is free of potential obstacles such as overpasses, bridges, and narrow roads. Groups known as "reconnaissance teams" will scout the way up to a year in advance as they identify problematic roads, cut down trees, and relocate utility poles. Turbine blades continue to increase in size, sometimes necessitating brand new logistical plans, as previously-used routes may not allow a larger blade. Specialized vehicles known as Schnabel trailers are custom-designed to load and transport turbine sections: tower sections can be loaded without a crane and the rear end of the trailer is steerable, allowing for easier maneuvering. Drivers must be specially trained.[91]

Jamg'arma

Wind turbines, by their nature, are very tall slender structures,[92] this can cause a number of issues when the structural design of the poydevor hisobga olinadi. The foundations for a conventional engineering structure are designed mainly to transfer the vertical yuk (dead weight) to the ground, this generally allows for a comparatively unsophisticated arrangement to be used. However, in the case of wind turbines, the force of the wind's interaction with the rotor at the top of the tower creates a strong tendency to tip the wind turbine over. This loading regime causes large moment loads to be applied to the foundations of a wind turbine. As a result, considerable attention needs to be given when designing the footings to ensure that the foundation will resist this tipping tendency.[93]

One of the most common foundations for offshor wind turbines is the monopile, a single large-diameter (4 to 6 metres) tubular steel pile driven to a depth of 5-6 times the diameter of the pile into the seabed. The cohesion of the soil, and friction between the pile and the soil provide the necessary structural support for the wind turbine.[94]

In onshore turbines the most common type of foundation is a gravity foundation, where a large mass of concrete spread out over a large area is used to resist the turbine loads. Wind turbine size & type, wind conditions and soil conditions at the site are all determining factors in the design of the foundation.[95] Some foundations are yig'ma.[96]

Xarajatlar

The modern wind turbine is a complex and integrated system. Structural elements comprise the majority of the weight and cost. All parts of the structure must be inexpensive, lightweight, durable, and manufacturable, under variable loading and environmental conditions. Turbine systems that have fewer failures,[99] require less maintenance, are lighter and last longer will lead to reducing the cost of wind energy.

One way to achieve this is to implement well-documented, validated analysis codes, according to a 2011 report from a coalition of researchers from universities, industry, and government, supported by the Barqaror kelajak uchun Atkinson markazi.[3]

The major parts of a modern turbine may cost (percentage of total): tower 22%, blades 18%, gearbox 14%, generator 8%.[100][101]

Dizayn spetsifikatsiyasi

The design specification for a wind-turbine will contain a power curve and guaranteed mavjudlik. With the data from the shamol resurslarini baholash it is possible to calculate commercial viability.[1]Odatda ish harorati range is −20 to 40 °C (−4 to 104 °F). In areas with extreme climate (like Ichki Mo'g'uliston yoki Rajastan ) specific cold and hot weather versions are required.

Wind turbines can be designed and validated according to IEC 61400 standartlar.[102]

RDS-PP (Reference Designation System for Power Plants) is a standardized system used worldwide to create structured hierarchy of wind turbine components. This facilitates turbine maintenance and operation cost, and is used during all stages of a turbine creation.[103]

Past harorat

Utility-scale wind turbine generators have minimum temperature operating limits which apply in areas that experience temperatures below −20 °C (−4 °F). Wind turbines must be protected from ice accumulation. Bu qila oladi anemometr readings inaccurate and which, in certain turbine control designs, can cause high structure loads and damage. Some turbine manufacturers offer low-temperature packages at a few percent extra cost, which include internal heaters, different lubricants, and different alloys for structural elements. If the low-temperature interval is combined with a low-wind condition, the wind turbine will require an external supply of power, equivalent to a few percent of its rated power, for internal heating. Masalan, Sent-Leon shamol xo'jaligi yilda Manitoba, Canada, has a total rating of 99 MW and is estimated to need up to 3 MW (around 3% of capacity) of station service power a few days a year for temperatures down to −30 °C (−22 °F). This factor affects the economics of wind turbine operation in cold climates.[iqtibos kerak ]

Shuningdek qarang

- Brushless wound-rotor doubly fed electric machine

- Suzuvchi shamol turbinasi

- Vertical-axis wind turbine

- Shamol turbinasi aerodinamikasi

- Copper in renewable energy, section Wind

- Noan'anaviy shamol turbinalari

Adabiyotlar

- ^ a b "Efficiency and performance" (PDF). Buyuk Britaniyaning biznes, korxona va tartibga soluvchi islohotlar vazirligi. Arxivlandi asl nusxasi (PDF) 2009-02-05 da. Olingan 2007-12-29.

- ^ "Wind turbine power curves". Olingan 18 mart 2017.

- ^ a b v d e f Alan T. Zehnder & Zellman Warhaft (27 July 2011). "University Collaboration on Wind Energy" (PDF). Kornell universiteti Barqaror kelajak uchun Atkinson markazi. Olingan 22 avgust 2011.

- ^ Weston, David (22 June 2017). "Vestas scales up to 4.2MW". Shamol kuchi oyiga. Olingan 10 sentyabr 2017.

- ^ https://www.ni.com/de-de/innovations/white-papers/08/wind-turbine-control-methods.html

- ^ http://researchhubs.com/post/engineering/wind-energy/pitch-regulated-and-stall-regulated-wind-turbine.html

- ^ Johnson, Scott J.; van Dam, C.P.; Berg, Dale E. (2008). "Active Load Control Techniques for Wind Turbines" (PDF). Sandia milliy laboratoriyasi. Olingan 13 sentyabr 2009.

- ^ "WINDExchange: World's Largest Offshore Wind Turbine Installed in Liverpool Bay". apps2.eere.energy.gov. Olingan 2017-02-27.

- ^ "WINDExchange: Utility-Scale Wind". apps2.eere.energy.gov. Olingan 2017-02-27.

- ^ Sagrillo, Mick (2010). "SMALL TURBINE COLUMN" (PDF). Windletter. 29 (1). Arxivlandi asl nusxasi (PDF) 2012 yil 26 aprelda. Olingan 19 dekabr 2011.

- ^ Funke (2017-06-09). "MHI Vestas launched the world's most powerful wind turbine". Offshore Wind Industry. Olingan 2018-01-24.

- ^ UK built half of Europe's offshore wind power in 2017 Guardian

- ^ "Shamol turbinasi ichi". AQSh Energetika vazirligi. Olingan 2017-02-27.

- ^ "The global wind energy market gears up for growth " Quvvat texnologiyasi / GlobalData, 18 September 2013 . Accessed: 16 October 2013.

- ^ "Magnit uzatmalar shamol turbinalarini mexanik uzatmalar qutisi bilan xayrlashishi mumkinmi?". machinedesign.com. 2014-06-19.

- ^ Navid Goudarzi (June 2013). "A Review on the Development of the Wind Turbine Generators across the World". International Journal of Dynamics and Control. Springer. 1 (2): 192–202. doi:10.1007/s40435-013-0016-y.

- ^ G. Bywaters, P. Mattila, D. Costin, J. Stowell, V. John, S. Hoskins, J. Lynch, T. Cole, A. Cate, C. Badger, and B. Freeman (October 2007). "Northern Power NW 1500 Direct-Drive Generator" (PDF). Qayta tiklanadigan energiya milliy laboratoriyasi. Subcontract Report NREL/SR-500-40177: iii.CS1 maint: bir nechta ism: mualliflar ro'yxati (havola)

- ^ "MEHDI-BOUZAIDA-avocat – Un site utilisant WordPress". www.reliawind.eu.

- ^ Vittrup, Sanne. PMs cause production problems Arxivlandi 2011-11-02 da Orqaga qaytish mashinasi Inglizcha tarjima Ing.dk, 1 November 2011. Accessed: 1 November 2011.

- ^ a b Chu, Stiven. Muhim materiallar strategiyasi[doimiy o'lik havola ] Amerika Qo'shma Shtatlari Energetika vazirligi, Dekabr 2011. Kirish: 23 dekabr 2011 yil.

- ^ Hau, Erich. "Wind Turbines: Fundamentals, Technologies, Application, Economics" p142. Springer Science & Business Media, 26. feb. 2013 yil. ISBN 3642271510

- ^ "Enercon's direct drive evolution". Olingan 2017-02-27.

- ^ Jamieson, Peter. Innovation in Wind Turbine Design sec11-1, John Wiley & Sons, 5 July 2011. Accessed: 26 February 2012. ISBN 1-119-97545-X

- ^ Kroo, Ilan. NASA Green Aviation Summit Arxivlandi 2011-10-18 da Orqaga qaytish mashinasi p9, NASA, September 2010. Accessed: 26 February 2012.

- ^ Berton, Toni; Jenkins, Nik; Sharp, Devid; Bossanyi, Ervin (2011). Wind Energy Handbook, Second Edition - Burton - Wiley Online Library. doi:10.1002/9781119992714. ISBN 9781119992714.

- ^ Söderbom, Johan (22 October 2020). "How ultra-capacitors are helping wind power generation realise its full potential". Energiyani saqlash bo'yicha yangiliklar. Arxivlandi asl nusxasidan 2020 yil 26 oktyabrda. Olingan 26 oktyabr 2020.

it is estimated that nearly 30% of all wind turbines globally are installed with ultra-capacitor systems

- ^ "Patent US5876181 - Multi-unit rotor blade system integrated wind turbine - Google Patents". Olingan 2013-11-06.

- ^ Eric Hau (ed), Wind Turbines Fundamentals, Technologies, Applications, Economics 2nd Edition, Springer 2006, ISBN 3-540-24240-6 sahifa 121

- ^ Hugh Piggott (1998). "CAT windpower course Blade design notes" (PDF).. Course notes from Scoraig Wind Electric, used in courses at the Muqobil texnologiyalar markazi.

- ^ Boel, Thomas (22 November 2012). "Two wings work". Ingeniøren. Olingan 22 noyabr 2012. Dizayn Arxivlandi 2012-12-05 da Orqaga qaytish mashinasi

- ^ "MY Secures Off-Shore Tender in Zhuhai, Guangdong Province, China with 3MW SCD Wind Turbine Generators, Construction to Begin in October 2013 Arxivlandi 2013-11-22 at Arxiv.bugun " WSPA, 30 September 2013. Accessed: 22 November 2013.

- ^ "2.5/2.75/3.0MW Series Wind Turbine Generator " Ming Yang. Accessed: 22 November 2013.

- ^ "4c Zhuhai "

- ^ a b v d e Ma, P.; Chjan, Y. (2014). "Perspectives of carbon nanotubes/polymer nanocomposites for wind blade materials. In". Qayta tiklanadigan va barqaror energiya sharhlari. 30: 651–660. doi:10.1016/j.rser.2013.11.008.

- ^ http://www.uotechnology.edu.iq/dep-laserandoptoelec-eng/branch/lectures/solid%20state/chapter%201%20classification%20of%20materail.pdf

- ^ Zbigniew Lubosny (2003). Wind Turbine Operation in Electric Power Systems: Advanced Modeling (Power Systems). Berlin: Springer. ISBN 978-3-540-40340-1.

- ^ "Materiallar va dizayn usullari 100 m pichoqni qidiradi". Windpower Engineering. 2011 yil 10-may. Olingan 22 avgust 2011.

- ^ Craig S. Collier (1 October 2010). "Samolyot qanotlaridan shamol turbinasi pichoqlariga: NASA dasturi Yerga yashil energiya dasturlari bilan qaytadi". NASA Tech qisqacha ma'lumotlari. Olingan 22 avgust 2011.

- ^ Nordex secures first N131/3000 in Finland In: Shamol kuchi oyiga, Retrieved 22. February 2015.

- ^ Weltgrößte Offshore-Turbine errichtet. In: Erneuerbare Energien. Das jurnali Retrieved 22. February 2015.

- ^ a b v d Griffin, Dayton A.; Ashwill, Thomas D. (2003). "Alternative Composite Materials for Megawatt-Scale Wind Turbine Blades: Design Considerations and Recommended Testing". Journal of Solar Energy Engineering. 125 (4): 515. doi:10.1115/1.1629750.

- ^ Ashwill, T; Laird D (January 2007). Concepts to Facilitate Very Large Blades (PDF). 45th AIAA Aerospace Sciences Meeting and Exhibit. AIAA-2007-0817.

- ^ Ronold, K. O.; Larsen, G. C. (2000). "Reliability-based design of wind-turbine rotor blades against failure in ultimate loading". Muhandislik tuzilmalari. 22 (6): 565–574. doi:10.1016/s0141-0296(99)00014-0.

- ^ Bassyouni, M.; Gutub, S. A. (2013). "Materials selection strategy and surface treatment of polymer composites for wind turbine blades fabrication". Polymers & Polymer Composites. 21 (7): 463–471. doi:10.1177/096739111302100708. S2CID 139958916.

- ^ Mishnaevsky, L.; Branner, K.; Beauson, J.; McGugan, M.; Sorensen, B. (2017). "Materials for Wind Turbine Blades: An Overview". Materiallar. 10 (11): 1285. Bibcode:2017Mate...10.1285M. doi:10.3390/ma10111285. PMC 5706232. PMID 29120396.

- ^ Niissen, R.P.L. (2006). "Fatigue life prediction and strength degradation of wind turbine rotor blade composites". Iqtibos jurnali talab qiladi

| jurnal =(Yordam bering) - ^ "Aerodynamic and Performance Measurements on a SWT-2.3- 101 Wind Turbine" (PDF). WINDPOWER 2011. Qayta tiklanadigan energiya milliy laboratoriyasi. 22–25 May 2011. p. 1. Olingan 14 oktyabr 2013.

- ^ Christou, P (2007). "Advanced materials for turbine blade manufacture". Reinforced Plastics. 51 (4): 22. doi:10.1016/S0034-3617(07)70148-0.

- ^ Surbhi, Vipin (14 September 2020). Low cost carbon fiber as potential lightning strike protection for wind turbine blades. American Society of Composites 2020. Texas.

- ^ Shen, R.; Amano, R. S.; Lewinski, G.; Matt, A.K.K. (2019). "A New Vascular System Highly Efficient in the Storage and Transport of Healing Agent for Self-Healing Wind Turbine Blades". Energiya resurslari texnologiyasi jurnali. 141 (5). doi:10.1115/1.4042916.

- ^ Zhang, N.; Yang, F.; Guerra, D.; Shen, C .; Castro, J.; Lee, J. L. (2013). "Enhancing particle erosion resistance of glass-reinforced polymeric composites using carbon nanofiber-based nano paper coatings". Amaliy polimer fanlari jurnali. 129 (4): 1875–1881. doi:10.1002/app.38899.

- ^ Liang, F.; Tang Y .; Gou, J.; Kapat, J. (2011). "Development of multifunctional nanocomposite coatings for wind turbine blades". Ceramic Transactions. Ceramic Transactions Series. 224: 325–336. doi:10.1002/9781118019467.ch32. ISBN 9781118019467.

- ^ Tang, M.; Xuang, L .; Vang, J .; Guan, D. (2019). "Research Progress of Blade Coatings in Wind Turbines". IOP konferentsiyalar seriyasi: Materialshunoslik va muhandislik. 542 (1): 012061. Bibcode:2019MS&E..542a2061T. doi:10.1088/1757-899X/542/1/012061.

- ^ Gao, L .; Liu Y.; Ma, L .; Hu, H. (2019). "A hybrid strategy combining minimized leading-edge electric-heating and superhydro-/ice-phobic surface coating for wind turbine icing mitigation". Qayta tiklanadigan energiya. 140: 943–956. doi:10.1016/j.renene.2019.03.112.

- ^ Mangini, D.; Antonini, C.; Marengo, M .; Amirfazli, A. (2015). "Runback ice formation mechanism on hydrophilic and superhydrophobic surfaces". Cold Regions Science and Technology. 109: 53–60. doi:10.1016/j.coldregions.2014.09.012.

- ^ a b Mishnaevsky, Leon; Branner, Kim; Petersen, Helga; Beauson, Justine; McGugan, Malcolm; Sørensen, Bent (9 November 2017). "Materials for Wind Turbine Blades: An Overview". Materiallar. 10 (11): 1285. Bibcode:2017Mate...10.1285M. doi:10.3390/ma10111285. PMC 5706232. PMID 29120396.

- ^ a b Dodd, Curtis W. (1983). How to Protect a Wind Turbine From Lightning. U.S. DEPARTMENT OF ENERGY Conservation and Renewable Energy Wind Energy Technology Division. 91-97 betlar.

- ^ "GLOBAL WIND ENERGY OUTLOOK 2008 | GWEC". www.gwec.net. Olingan 2016-11-07.

- ^ The European Wind Energy Association. "Research note outline on recycling wind turbines blades" (PDF).

- ^ Gignac, James (2 November 2020). "Recycling Wind Turbine Blades". CleanTechnica. UCS. Arxivlandi from the original on 2 November 2020.

- ^ a b Duflou, Joost R.; Deng, Yelin; Acker, Karel Van; Dewulf, Wim (2012-04-01). "Do fiber-reinforced polymer composites provide environmentally benign alternatives? A life-cycle-assessment-based study". MRS byulleteni. 37 (4): 374–382. doi:10.1557/mrs.2012.33. ISSN 1938-1425.

- ^ Pickering, S. J. (2006-08-01). "Recycling technologies for thermoset composite materials—current status". Composites Part A: Applied Science and Manufacturing. The 2nd International Conference: Advanced Polymer Composites for Structural Applications in Construction. 37 (8): 1206–1215. doi:10.1016/j.compositesa.2005.05.030.

- ^ "Recycling of wind turbine blades - Appropedia: The sustainability wiki". www.appropedia.org. Olingan 2016-11-08.

- ^ "ReFiber ApS Wind Turbine Blade Recycling Technology".

- ^ Asmatulu, Eylem (February 2013). "Recycling of fiber-reinforced composites and direct structural composite recycling concept". Journal of Composite Materials. 48 (5): 13–14. doi:10.1177/0021998313476325. S2CID 136516595.

- ^ "Wind Turbine Blades Can't Be Recycled, So They're Piling Up in Landfills".

- ^ "Indiana's Renewable Energy Resources". Indianacleanpower.org. 2013-08-07. Arxivlandi asl nusxasi 2014-02-09 da. Olingan 2013-11-06.

- ^ a b Emme, Svend. New type of wind turbine tower Arxivlandi 2012-04-26 da Orqaga qaytish mashinasi Metal Industry, 8 August 2011. Accessed: 10 December 2011.

- ^ Vittrup, Sanne. Ny type vindmølletårn samles af lameller, Ingeniøren, 29. October 2011. Accessed: 12 May 2013.

- ^ "The shell tower in brief Arxivlandi 2013-03-15 da Orqaga qaytish mashinasi ". Andresen Towers. Retrieved: 13 November 2012.

- ^ Lund, Morten. Robotter bag dansk succes med vindmølletårne, Ingeniøren, 12 May 2013. Accessed: 12 May 2013.

- ^ "WindPACT Turbine Design: Scaling Studies Technical Area 3 -- Self-Erecting Tower and Nacelle Feasibility".2001.

- ^ R. D. Fredrickson."A self-erecting method for wind turbines.".2003.

- ^ Nic Sharpley."What’s holding up tower technology?".2013.

- ^ "Self-Erecting Wind Turbine Designed for Remote Sites".2002.

- ^ Ancona, Dan, and Jim McVeigh. (2011): Wind Turbine - Materials and Manufacturing Fact Sheet. Princeton Energy Resources International, LLC, 19 Aug. 2001. Web. 21 Oct. 2015. <http://www.perihq.com/documents/WindTurbine-MaterialsandManufacturing_FactSheet.pdf >.

- ^ ""Steel Solutions in the Green Economy." (2015): Wind Turbines. World Steel Association, 2012. Web. 21 Oct. 2015. <https://www.worldsteel.org/dms/internetDocumentList/bookshop/worldsteel-wind-turbines-web/document/Steel%20solutions%20in%20the%20green%20economy:%20Wind%20turbines.pdf Arxivlandi 2015-08-14 da Orqaga qaytish mashinasi >.

- ^ Quilligan, Aidan; O'Connor, A.; Pakrashi, V. (2012). "Fragility analysis of steel and concrete wind turbine towers". Muhandislik tuzilmalari. 36: 270–282. doi:10.1016/j.engstruct.2011.12.013. hdl:10197/10425.

- ^ "Arxivlangan nusxa" (PDF). Arxivlandi asl nusxasi (PDF) 2016-03-04 da. Olingan 2015-10-22.CS1 maint: nom sifatida arxivlangan nusxa (havola)

- ^ Levitan, Deyv. "Chelik uchun juda baland: muhandislar shamol turbinasi dizaynini yangi balandlikka ko'tarish uchun betonni qidirmoqdalar." IEEE Spectrum, 2013 yil 16-may. Veb. 21 oktyabr 2015 yil. <https://spectrum.ieee.org/energywise/green-tech/wind/too-tall-for-steel-engineers-look-to-crete-to-take-wind-turbine-design-to-new-heights >.

- ^ Makgar, Jastin. "Shamol energetikasi inqilobi: Dunyodagi birinchi yog'och turbinasi Arxivlandi 2012-11-16 da Orqaga qaytish mashinasi " Dizayn yaratish manbai, 13 Noyabr 2012. Qabul qilingan: 2012 yil 13-noyabr.

- ^ RICHARDSON, JEYK. "Shamol turbinalari uchun 99% tabiiy yog'och minorasi " Technica-ni tozalang, 18 oktyabr 2012. Qabul qilingan: 2012 yil 13-noyabr.

- ^ P. V. Karlin, A. S. Laksson va E. B. Muljadi."O'zgaruvchan tezlikda ishlaydigan turbinalar texnologiyasining san'ati tarixi va holati".2003-bet. 130-131.

- ^ Murty, S.S .; Singh, B .; Goel, P.K .; Tivari, S.K. (2007). "Ruxsat etilgan tezlik va o'zgaruvchan tezlikni shamolni energiyani konversiyalash tizimlarini tarmoqqa oziqlantirishni qiyosiy o'rganish". 2007 yil elektr energiyasi va haydovchi tizimlari bo'yicha 7-xalqaro konferentsiya: 736–743. doi:10.1109 / PEDS.2007.4487785. ISBN 978-1-4244-0644-9. S2CID 22529780.

- ^ a b Caliao, Nolan D. (2011). "To'liq nominal konvertorli shamol turbinalarini dinamik modellashtirish va boshqarish". Qayta tiklanadigan energiya. 36 (8): 2287–2297. doi:10.1016 / j.renene.2010.12.025.

- ^ E. Muljadi va C.P. Butterfild."Tezlikni boshqaruvchi o'zgaruvchan tezlikda ishlaydigan shamol turbinasi avlodi".1999.

- ^ E. Muljadi, K. Pirs va P. Migliore."O'zgaruvchan tezlikda to'xtab turadigan shamol turbinalarini boshqarish bo'yicha konservativ strategiya" Arxivlandi 2014-03-20 da Orqaga qaytish mashinasi.2000.

- ^ Evays, AM; Liang, J .; Ekanayake, JB .; Jenkins, N. (2012). "To'liq baholangan konvertorli shamol turbinalarining SSRga ta'siri". IEEE PES Innovatsion Smart Grid Technologies: 1–6. doi:10.1109 / ISGT-Asia.2012.6303160. ISBN 978-1-4673-1220-2. S2CID 34726034.

- ^ Mate Jelavich, Nedjelko Perich, Ivan Petrovich."Rotor tezligini boshqarish orqali shamol turbinasi minorasi tebranishlarini susaytirish". 2007.

- ^ Rodriges t., A .; Carcangiu, C. E.; Pineda, I .; Fischer, T .; Khnle, B .; Scheu, M .; Martin, M. (2011). "Minora yukini kamaytirish uchun shamol turbinasining strukturaviy amortizatorini boshqarish". Qurilish inshootlari mavzulari, 4-jild. Eksperimental mexanika seriyasining jamiyat konferentsiyasi materiallari. 141-153 betlar. doi:10.1007/978-1-4419-9316-8_12. ISBN 978-1-4419-9315-1.

- ^ Beyker, Linda (2019 yil 27-avgust). "Shamol turbinalarini etkazib berish shabada emas". Yuk to'lqinlari. Olingan 29 avgust 2019.

- ^ Lombardi, D. (2010). Mono-qoziqni qo'llab-quvvatlanadigan offshor shamol turbinalarining uzoq muddatli ishlashi. Bristol: Bristol universiteti.

- ^ Cox, J. A., & Jones, C. (2010). Sucking Caisson-ning qo'llab-quvvatlanadigan offshor shamol turbinalarini uzoq muddatli ishlashi. Bristol: Bristol universiteti.

- ^ Gevin, Kennet; Kreyg, Uilyam (2018). Shamol turbinasi asoslari. London: ICE Publishing. 3-24 betlar. ISBN 9780727763969.

- ^ Ashlok, Jerami; Sheefer, Verne. "Shamolli turbinalar uchun asoslar" (PDF). Ayova shtati. Olingan 21 avgust 2018.

- ^ "Shamol turbinasi asoslarining yangi texnologiyasi". www.windtech-international.com. 9 Noyabr 2020. Arxivlandi asl nusxasidan 2020 yil 9-noyabrda.

2020 yil oktyabridan boshlab poydevorlar ommaviy ishlab chiqarilmoqda

- ^ "Blade Dragon". Yashil davlat. Olingan 13 dekabr 2012.

- ^ R. Simonsen, Torben. "Liftra indstiller Blade Dragon". Arxivlandi asl nusxasi 2013-02-03 da. Olingan 13 dekabr 2012.

- ^ Budni, Rob. Rulman etishmovchiligi shamol turbinalari uchun jiddiy muammolarni keltirib chiqaradi, ammo echimlar mavjud | Machine Design Magazine, 2014 yil 26-iyun.

- ^ Jeymison, Piter. Shamol turbinasi dizaynidagi innovatsiyalar p155, John Wiley & Sons, 7 Iyul 2011. Kirish: 26 fevral 2012 yil. ISBN 0-470-69981-7

- ^ Jeymison, Piter. Shamol turbinasi dizaynidagi innovatsiyalar sek9-1, John Wiley & Sons, 7 Iyul 2011. Kirish: 26 fevral 2012 yil. ISBN 1-119-97612-X

- ^ Xalqaro standart IEC 61400-1, Uchinchi nashr Xalqaro elektrotexnika komissiyasi, Avgust 2005. Kirish: 2011 yil 12 mart.

- ^ "RDS-PP belgilash bo'yicha xizmatlar". Keel Qarori. Olingan 2019-07-09.

Qo'shimcha o'qish

- Robert Gasch, Jochen Twele (tahr.), Shamol elektr stantsiyalari. Asoslari, dizayni, qurilishi va ishlatilishi, Springer 2012 yil ISBN 978-3-642-22937-4.

- Pol Gipe, tahrir. (2004). Shamol kuchi: uy, fermer xo'jaligi va biznes uchun qayta tiklanadigan energiya (ikkinchi nashr). Chelsi Yashil nashriyot kompaniyasi. ISBN 978-1-931498-14-2.

- Erix Xau, Shamol turbinalari: asoslari, texnologiyalari, qo'llanilishi, iqtisodiyoti Springer, 2013 yil ISBN 978-3-642-27150-2 (Google Books-da oldindan ko'rish)

- Zigfrid Xayer, Shamol energiyasini konversiyalash tizimlarining tarmoqqa integratsiyasi Vili 2006 yil, ISBN 978-0-470-86899-7.

- Piter Jeymison, Shamol turbinasi dizaynidagi innovatsiyalar. Wiley & Sons 2011 yil, ISBN 978-0-470-69981-2

- Devid Spera (ed,) Shamol turbinasi texnologiyasi: shamol turbinasi muhandisligining asosiy tushunchalari, Ikkinchi nashr (2009), ASME Press, ISBN 9780791802601

- Alois Sheffarczyk (tahr.), Shamol energetikasi texnologiyasini tushunish, Wiley & Sons 2014, ISBN 978-1-118-64751-6.

- Vey Tong, tahrir. (2010). Shamol energiyasini ishlab chiqarish va shamol turbinasini loyihalash. WIT tugmasini bosing. ISBN 978-1-84564-205-1.

- Hermann-Josef Wagner, Jyotirmay Mathur, Shamol energetikasi tizimlari bilan tanishish. Asoslari, texnologiyasi va ishlashi. Springer 2013 yil, ISBN 978-3-642-32975-3.