Bug 'turbinasi - Steam turbine

A bug 'turbinasi ekstrakti chiqaradigan qurilma issiqlik energiyasi bosim ostida bug ' va buni amalga oshirish uchun foydalanadi mexanik ish aylanadigan chiqish milida. Uning zamonaviy namoyishi tomonidan ixtiro qilingan Charlz Parsons 1884 yilda.[1][2]

Bug 'turbinasi issiqlik mexanizmi bu uning yaxshilanishining katta qismini oladi termodinamik samaradorlik bug'ni kengaytirishda bir necha bosqichlardan foydalanishdan kelib chiqadi, bu esa ideal qaytariladigan kengayish jarayoniga yaqinroq yondoshishga olib keladi. Chunki turbin hosil qiladi aylanma harakat, ayniqsa, haydovchi uchun foydalanish uchun juda mos keladi elektr generatori - 2014 yilda Qo'shma Shtatlarda ishlab chiqarilgan elektr energiyasining 85% ga yaqini bug 'turbinalaridan foydalangan.[3]

Tarix

Reaksiya bug 'turbinasi deb tasniflanishi mumkin bo'lgan birinchi qurilma klassik, o'yinchoqdan biroz ko'proq edi Aeolipile tomonidan 1-asrda tasvirlangan Iskandariya qahramoni yilda Rim Misr.[4][5] 1551 yilda, Toqi ad-Din yilda Usmonli Misr aylanadigan a amaliy qo'llanilishi bilan bug 'turbinasini tavsifladi tupurish. Bug 'turbinalari ham italiyalik tomonidan tavsiflangan Jovanni Branka (1629)[6] va Jon Uilkins Angliyada (1648).[7][8] Taqi ad-Din va Uilkins tomonidan tasvirlangan qurilmalar bugungi kunda shunday tanilgan bug 'jaklari. 1672 yilda impulsli bug 'turbinasi boshqariladigan avtomobil tomonidan ishlab chiqilgan Ferdinand Verbiest. Ushbu avtoulovning yanada zamonaviy versiyasi 18-asrning oxirlarida bir muncha vaqt noma'lum nemis mexanigi tomonidan ishlab chiqarilgan. 1775 yilda Sohoda Jeyms Vatt u erda ishga tushirilgan reaksiya turbinasini ishlab chiqdi.[9] 1827 yilda frantsuzlar Real va Pichon patentlangan va aralash impuls turbinasini qurishgan.[10]

Zamonaviy bug 'turbinasi 1884 yilda ixtiro qilingan Charlz Parsons, uning birinchi modeli a ga ulangan Dinamo 7,5 kilovatt (10,1 ot kuchiga teng) elektr energiyasini ishlab chiqargan.[11] Parsonsning bug 'turbinasi ixtirosi arzon va mo'l-ko'l elektr energiyasini yaratishga imkon berdi va dengiz transporti va dengiz urushida inqilob qildi.[12] Parsonsning dizayni a reaktsiya turi. Uning patenti litsenziyalangan va turbinasi tez orada amerikalik tomonidan kengaytirilgan, Jorj Vestingxaus. Parsons turbinasini ham kattalashtirish oson bo'ldi. Parsons o'zining ixtirosini barcha yirik elektr stantsiyalari uchun qabul qilinganligini ko'rib mamnun bo'ldi va generatorlar hajmi uning birinchi 7,5 kilovattdan (10,1 ot kuchiga teng) 50 000 kilovatt (67 000 ot kuchiga) ega bo'lgan birliklarga qadar o'sdi. Parsonsning hayoti davomida birlikning ishlab chiqarish quvvati taxminan 10 000 baravarga ko'paytirildi,[13] va uning firmasi tomonidan qurilgan turbo-generatorlardan jami ishlab chiqarish C. A. Parsons va kompaniyasi va ularning litsenziyalari tomonidan faqat er maqsadlarida o'ttiz million ot kuchidan oshib ketgan.[11]

Bug 'bilan samarali ishlaydigan turbinalarning boshqa variantlari ishlab chiqilgan. The de Laval turbinasi (ixtiro qilgan Gustaf de Laval ) bug 'turbinasi pichog'iga qarshi ishlatishdan oldin uni maksimal tezlikda tezlashtirdi. De Lavalniki impuls turbinasi oddiyroq va arzonroq va bosim o'tkazmaydigan bo'lishi shart emas. U bug 'har qanday bosimi bilan ishlashi mumkin, ammo unchalik samarasiz.[iqtibos kerak ] Ogyust Rateau 1896 yildayoq de Laval printsipidan foydalangan holda bosimli aralash impuls turbinasini ishlab chiqdi,[14] 1903 yilda AQSh patentini oldi va 1904 yilda turbinani frantsuz torpedo qayig'iga tatbiq etdi. École des mines de Saint-Etienne o'n yil davomida 1897 yilgacha va keyinchalik muvaffaqiyatli kompaniyani tashkil etdi Alstom vafotidan keyin qat'iy. Bug 'va gaz turbinalarining zamonaviy nazariyasining asoschilaridan biri edi Aurel Stodola, slovak fizigi va muhandisi va Shveytsariya Politexnika institutining professori (hozirda) ETH ) Tsyurixda. Uning ishi Die Dampfturbinen und ihre Aussichten als Wärmekraftmaschinen (Ingliz tili: Bug 'turbinasi va undan issiqlik dvigateli sifatida foydalanish) 1903 yilda Berlinda nashr etilgan. Keyingi kitob Dampf und Gas-Turbinen (Inglizcha: Bug 'va gaz turbinalari) 1922 yilda nashr etilgan.[15]

The Jigarrang-Kertis turbinasi, dastlab AQShning International Curtis Marine Turbine Company kompaniyasi tomonidan ishlab chiqilgan va patentlangan impuls turi, 1900 yillarda ishlab chiqarilgan John Brown & Company. U Jon Braun motorli savdo kemalarida va harbiy kemalarida, shu jumladan laynerlarda va qirollik dengiz kuchlari harbiy kemalarida ishlatilgan.

Ishlab chiqarish

Bug 'turbinalarini ishlab chiqarish sanoatida Xitoyning energiya uskunalari ishlab chiqaruvchilari ustunlik qilmoqda. Harbin Electric, Shanxay elektr va Dongfang Electric, Xitoyda energiya uskunalarini ishlab chiqaruvchi uchta etakchi kompaniya, 2009-10 yillarda bug 'turbinalarining butun dunyo bozoridagi ulushini birgalikda egallaydi. Plitalar.[16] Bozor ulushiga ega bo'lmagan boshqa ishlab chiqaruvchilar kiradi Bharat Heavy Electrics Limited, Simens, Alstom, General Electric, Doosan Škoda Power, Mitsubishi Heavy Industries va Toshiba.[16] Frost & Sallivan konsalting kompaniyasi bug 'turbinalarini ishlab chiqarish 2020 yilga kelib yanada mustahkamlanib borishini loyihalashtiradi, chunki xitoylik elektr ishlab chiqaruvchilar Xitoydan tashqarida tobora ortib borayotgan biznesda g'alaba qozonishadi.[17]

Turlari

Bug 'turbinalari nasoslar, kompressorlar va boshqa vallar bilan ishlaydigan uskunalar uchun mexanik qo'zg'alish sifatida ishlatiladigan kichik <0,75 kVt (<1 ot kuchiga ega) birliklardan (kamdan-kam) tortib, elektr energiyasini ishlab chiqarish uchun ishlatiladigan 1500 MVt (200000 ot kuchiga ega) turbinalarga qadar turli o'lchamlarda ishlab chiqariladi. . Zamonaviy bug 'turbinalari uchun bir necha tasnif mavjud.

Pichoq va sahna dizayni

Turbinali pichoqlar ikkita asosiy turga bo'linadi: pichoqlar va nozullar. Bug'ning ularga ta'siri tufayli pichoqlar butunlay harakatlanadi va ularning profillari birlashmaydi. Bu bug 'tezligining pasayishiga olib keladi va bug' pichoqlar bo'ylab harakatlanayotganda bosim pasaymaydi. Belgilangan shtutserlar bilan almashinadigan pichoqlardan tashkil topgan turbin an impuls turbinasi, Kertis turbinasi, Rateau turbinasi, yoki Jigarrang-Kertis turbinasi. Nozzellar pichoqlarga o'xshash ko'rinadi, ammo ularning profillari chiqish joyiga yaqinlashadi. Bug'ning nozullar bo'ylab harakatlanishi natijasida bug 'bosimining pasayishi va tezligi oshishiga olib keladi. Nozullar bug'ning ham ularga ta'siri, ham chiqishda yuqori tezlikli bug 'tufayli reaktsiya tufayli harakatlanadi. Belgilangan shtutserlar bilan almashinadigan harakatlanuvchi nozullardan tashkil topgan turbinaga a deyiladi reaktsiya turbinasi yoki Parsons turbinasi.

Kam quvvatli dasturlardan tashqari, turbinali pichoqlar ketma-ket bir necha bosqichda joylashgan bo'lib, ular chaqiriladi birikma, bu juda yaxshilanadi samaradorlik past tezlikda.[18] Reaksiya bosqichi - bu sobit shtutserlar qatori, so'ngra harakatlanuvchi nozullar qatori. Bir nechta reaktsiya bosqichlari bug 'kirishi va chiqindisi orasidagi bosimning pasayishini ko'plab kichik tomchilarga ajratadi, natijada a bosim bilan biriktirilgan turbin. Impuls bosqichlari bosim bilan biriktirilgan, tezlik bilan biriktirilgan yoki bosim tezligi bilan biriktirilgan bo'lishi mumkin. Bosim bilan biriktirilgan impuls pog'onasi - biriktirilgan bir necha pog'onali harakatlanuvchi pichoqlar qatoridan keyin sobit nozullar qatori. Bu ixtirochisidan keyin Rateau turbinasi deb ham ataladi. A tezlik bilan biriktirilgan impuls bosqichi (Kurtis tomonidan ixtiro qilingan va "Kertis g'ildiragi" deb ham nomlangan) - bu sobit pichoqlar qatori, so'ngra ikki yoki undan ortiq qatorlar harakatlanuvchi pichoqlar qatorlari bilan o'zgarib turadi. Bu sahna bo'ylab tezlik pasayishini bir necha kichik tomchilarga ajratadi.[19] Tezlik qo'shilgan impuls bosqichlarining bir qatoriga a deyiladi bosim tezligi biriktirilgan turbin.

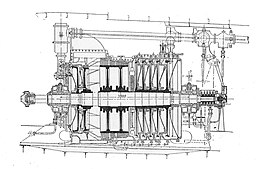

1905 yilga kelib, tezkor kemalarda bug 'turbinalari foydalanishga topshirilganda (masalan HMSQo'rquv ) va quruqlikdagi elektr energiyasidan foydalanishda, ko'p bosqichli turbinaning boshida (bug 'bosimi eng yuqori bo'lgan joyda) bir yoki bir nechta Kertis g'ildiraklaridan, keyin esa reaktsiya bosqichlaridan foydalanish maqsadga muvofiqligi aniqlandi. Bu turbinali rotor va korpus o'rtasida qochqinning pasayishi tufayli yuqori bosimli bug 'bilan samaraliroq edi.[20] Bu nemis 1905 yilgi rasmida tasvirlangan AEG dengiz bug 'turbinasi. Bug ' qozonxonalar a orqali yuqori bosim ostida o'ng tomondan kiradi gaz, operator tomonidan qo'lda boshqariladi (bu holda a dengizchi gaz chiqaruvchi sifatida tanilgan). U past bosim ostida chiqishdan oldin beshta Kertis g'ildiraklaridan va ko'plab reaktsiya bosqichlaridan (o'rtada ikkita katta rotor chetidagi kichik pichoqlardan) o'tib, deyarli kondensator. Kondensator bug'dan olinadigan energiyani maksimal darajada oshiradigan vakuumni ta'minlaydi va bug'ni quyultiradi ozuqa suvi qozonxonalarga qaytarilishi kerak. Chap tomonda turbinani teskari yo'nalishda aylantiradigan bir nechta qo'shimcha reaktsiya bosqichlari (ikkita katta rotorda), bug 'alohida gaz bilan qabul qilinadi. Kemalar kamdan-kam hollarda teskari yo'nalishda ishlatilganligi sababli, samolyot turbinalarida samaradorlik ustuvor ahamiyatga ega emas, shuning uchun xarajatlarni tejash uchun faqat bir necha bosqichlardan foydalaniladi.

Pichoq dizayni bilan bog'liq muammolar

Turbinalar konstruktsiyasiga duch keladigan asosiy muammo bu kamaytirish edi sudralmoq pichoqlar tomonidan tajribali. Yuqori harorat va yuqori ish streslari tufayli bug 'turbinasi materiallari ushbu mexanizmlar orqali buziladi. Turbinaning samaradorligini oshirish uchun harorat ko'tarilganda, sudralish muhim ahamiyatga ega bo'ladi. So'rishni cheklash uchun, termal qoplamalar va superalloydlar qattiq eritmani kuchaytirish bilan va don chegarasini mustahkamlash pichoq dizaynida ishlatiladi.

Himoya qoplamalari issiqlik shikastlanishini kamaytirish va cheklash uchun ishlatiladi oksidlanish. Ushbu qoplamalar ko'pincha stabillashadi zirkonyum dioksid - asosli keramika. Termal himoya qoplamasidan foydalanish nikel superalloyning harorat ta'sirini cheklaydi. Bu pichoqda tajribali sudralib yurish mexanizmlarini pasaytiradi. Oksidlanish qoplamalari pichoqlar tashqarisida to'planish natijasida hosil bo'ladigan yo'qotishlarni cheklaydi, bu ayniqsa yuqori haroratli muhitda muhimdir.[21]

Nikel asosidagi pichoqlar alyuminiy va titanium bilan qotishma bilan mustahkamlanib, chidamliligini yaxshilaydi. The mikroyapı Ushbu qotishmalar tarkibiga turli mintaqalar kiradi. Gamma-boshlang'ich fazaning bir tekis tarqalishi - nikel, alyuminiy va titanning kombinatsiyasi - mikroyapı tufayli pichoqning mustahkamligi va sudralishiga qarshilik qiladi.[22]

Olovga chidamli kabi elementlar reniy va ruteniy qotishma tarkibiga suzish kuchini yaxshilash uchun qo'shilishi mumkin. Ushbu elementlarning qo'shilishi gamma boshlang'ich fazasining tarqalishini kamaytiradi va shunday saqlaydi charchoq qarshilik, kuch va sudralishga qarshilik.[23]

Bug 'etkazib berish va egzoz sharoitlari

Turbin turlariga kondensatsiya, kondensatsiyalanmaydigan, qizdirish, ekstraktsiya va induksiya kiradi.

Kondensatlovchi turbinalar ko'pincha elektr stantsiyalarida uchraydi. Ushbu turbinalar a dan bug 'oladi qozon va uni a kondensator. Tugagan bug 'atmosferada ancha past bosim ostida va qisman quyultirilgan holatda, odatda a sifat 90% ga yaqin.

Kondensatsiyalanmaydigan yoki orqaga bosimli turbinalar texnologik bug 'ishlatishda eng ko'p qo'llaniladi, bunda bug' turbinadan chiqqandan keyin qo'shimcha maqsadlar uchun ishlatiladi. Egzoz bosimi jarayon bug 'bosimining ehtiyojlarini qondirish uchun tartibga soluvchi valf bilan boshqariladi. Ular odatda neftni qayta ishlash zavodlarida, markaziy isitish punktlarida, sellyuloza-qog'oz zavodlarida va tuzsizlantirish ko'p miqdordagi past bosimli texnologik bug 'kerak bo'lgan ob'ektlar.

Isitish turbinalari deyarli faqat elektr stantsiyalarida qo'llaniladi. Qayta isitish turbinasida bug 'oqimi turbinaning yuqori bosimli qismidan chiqib ketadi va qo'shimcha supero'tkazgich qo'shilgan qozonga qaytariladi. Keyin bug 'turbinaning oraliq bosim qismiga qaytadi va uning kengayishini davom ettiradi. Bir tsikldagi qayta isitishni ishlatish turbinadan ish hajmini oshiradi va kengayish bug 'kondensatsiyalanguncha xulosaga keladi va shu bilan pichoqlarning oxirgi qatorlaridagi eroziyasini minimallashtiradi. Ko'pgina hollarda, tsiklda ishlatiladigan maksimal isitish soni 2 ga teng, chunki bug'ni haddan tashqari qizdirish narxi turbinadan ish hajmining ko'payishini inkor etadi.

Ekstraktsion turbinalar barcha dasturlarda keng tarqalgan. Ekstraktsiyali turbinada bug 'turbinaning turli bosqichlaridan ajralib chiqadi va sanoat jarayonining ehtiyojlari uchun ishlatiladi yoki qozonga yuboriladi. ozuqa suv isitgichlari tsiklning umumiy samaradorligini oshirish. Ekstraktsiya oqimlari valf bilan boshqarilishi yoki nazoratsiz qoldirilishi mumkin. Olingan bug 'natijasida a kuchni yo'qotish turbinaning quyi oqim bosqichlarida.

Induksion turbinalar qo'shimcha quvvat olish uchun oraliq bosqichda past bosimli bug 'chiqaradi.

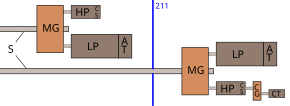

Koson yoki o'qni tartibga solish

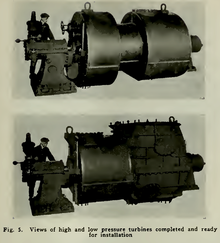

Ushbu tartiblarga bitta korpus, tandemli birikma va o'zaro faoliyat turbinalar kiradi. Yagona korpus birliklari - bu bitta korpus va mil generator bilan bog'langan eng asosiy uslubdir. Tandem birikmasi ikkita yoki undan ortiq korpus to'g'ridan-to'g'ri bir generatorni boshqarish uchun birlashtirilgan joyda ishlatiladi. O'zaro faoliyat turbinali tartib ikki yoki undan ortiq valga ega bo'lib, ular tez-tez turli xil tezlikda ishlaydigan ikki yoki undan ortiq generatorlarni boshqaradi. O'zaro faoliyat turbinadan odatda ko'plab yirik dasturlar uchun foydalaniladi. 1930-yillarning 1960-yillariga oid odatiy dengiz inshooti quyida keltirilgan; bu yuqori va past bosimli turbinalarni umumiy reduktor mexanizmini boshqarishini, bitta yuqori bosimli turbinada tishli kruiz turbinasini ko'rsatadi.

Ikki oqimli rotorlar

Harakatlanuvchi bug 'turbina miliga ham teginal, ham eksenel tortish kuchini beradi, ammo oddiy turbinadagi eksenel tortishuvga qarshilik ko'rsatilmaydi. To'g'ri rotor holatini va muvozanatni saqlash uchun bu kuchga qarshi kuch tomonidan qarshi turish kerak. Bosish podshipniklari milya rulmanlari uchun ishlatilishi mumkin, rotor qo'g'irchoq pistonlardan foydalanishi mumkin, shunday bo'lishi mumkin er-xotin oqim- bug 'milning o'rtasiga kirib, ikkala uchidan chiqadi yoki ularning har qandayining kombinatsiyasi. A er-xotin oqim Rotor, har ikkala yarmidagi pichoqlar qarama-qarshi tomonga buriladi, shuning uchun eksenel kuchlar bir-birini inkor qiladi, ammo teginal kuchlar birgalikda harakat qiladi. Rotorning ushbu dizayni ham deyiladi ikki oqim, ikki eksenel oqim, yoki er-xotin egzoz. Ushbu tartib aralash turbinaning past bosimli korpuslarida keng tarqalgan.[24]

Ishlash va loyihalashtirish printsipi

Ideal bug 'turbinasi an deb hisoblanadi izentropik jarayon, yoki turbinaga kiradigan bug 'entropiyasi turbinadan chiqayotgan bug' entropiyasiga teng bo'lgan doimiy entropiya jarayoni. Hech qanday bug 'turbinasi chindan ham izentropik emas, ammo turbinani qo'llash asosida tipik izentropik samaradorlik 20 dan 90% gacha. Turbinaning ichki qismi bir nechta pichoqlar to'plamini yoki chelaklar. Statsionar pichoqlarning bir to'plami korpusga va aylanadigan pichoqlarning bir to'plami valga ulangan. To'plamlar har bir bosqichda bug 'kengayishini samarali ishlatish uchun to'plamlarning o'lchamlari va konfiguratsiyasi o'zgarib turadigan ma'lum minimal bo'shliqlar bilan birlashtirilgan.

Bug 'turbinasining amaliy issiqlik samaradorligi turbinaning kattaligi, yuk holati, bo'shliq yo'qolishi va ishqalanish yo'qotishlariga qarab farq qiladi. Ular 1200 MVt (1600000 ot kuchiga ega) turbinada taxminan 50% gacha yuqori ko'rsatkichlarga erishadilar; kichikroq samaradorligi pastroq.[iqtibos kerak ] Turbinaning samaradorligini oshirish uchun bug 'bir necha bosqichda ish olib boradi. Ushbu bosqichlar energiyaning ulardan olinishi bilan tavsiflanadi va impuls yoki reaksiya turbinalari sifatida tanilgan. Ko'pgina bug 'turbinalarida reaktsiya va impuls konstruktsiyalari aralashmasi ishlatiladi: har bir bosqich o'zini o'zi yoki boshqasini tutadi, ammo umumiy turbinada ikkalasi ham ishlatiladi. Odatda, quyi bosim bo'limlari reaktsiya turi va yuqori bosim bosqichlari impuls turi hisoblanadi.[iqtibos kerak ]

Impuls turbinalari

Impulsli turbinada bug 'oqimini yuqori tezlikda harakatlanadigan oqimlarga yo'naltiruvchi sobit shtutserlar mavjud. Ushbu jetlar muhim kinetik energiyani o'z ichiga oladi, bu esa paqirga o'xshash shakldagi rotor pichoqlari orqali milning aylanishiga aylanadi, chunki bug 'oqimi yo'nalishini o'zgartiradi. Bosimning pasayishi faqat statsionar pichoqlar bo'ylab sodir bo'ladi, bunda bug 'tezligi aniq oshadi va bug' nasab orqali oqib o'tganda uning bosimi kirish bosimidan chiqish bosimiga tushadi (atmosfera bosimi yoki odatda, kondensator vakuumi). . Bug'ning kengayishining ushbu yuqori nisbati tufayli bug 'juda yuqori tezlik bilan nozulni tark etadi. Harakatlanuvchi pichoqlardan chiqib ketadigan bug 'shtutserdan chiqayotganda bug'ning maksimal tezligining katta qismiga ega. Ushbu yuqori chiqish tezligi tufayli energiyani yo'qotish odatda tezlikni ko'tarish yoki yo'qotish yo'qotish deb ataladi.

Ning qonuni momentum momenti vaqtincha egallab turgan suyuqlikka ta'sir qiluvchi tashqi kuchlar momentlari yig'indisi ovoz balandligini boshqarish nazorat hajmi orqali burchak momentum oqimining aniq vaqt o'zgarishiga teng.

Aylanadigan suyuqlik radiusda boshqarish hajmiga kiradi tangensial tezlik bilan va radiusda qoldiradi tangensial tezlik bilan .

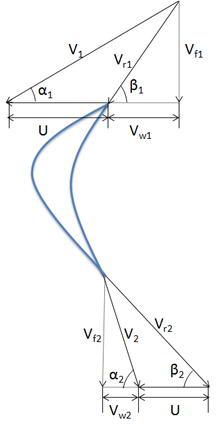

A tezlik uchburchagi turli tezliklarning o'zaro bog'liqligini yaxshiroq tushunishga yo'l ochib beradi. Qo'shni rasmda bizda:

- va mos ravishda kirish va chiqishdagi mutloq tezliklar.

- va mos ravishda kirish va chiqishdagi oqim tezligi.

- va harakatlanuvchi mos yozuvlar mos ravishda kirish va chiqish joyidagi burilish tezligi.

- va mos ravishda kirish va chiqishdagi nisbiy tezliklar.

- va mos ravishda kirish va chiqish joyidagi pichoqning tezligi.

- yo'naltiruvchi qanot burchagi va pichoq burchagi.

Keyin momentum momenti qonuni bo'yicha suyuqlikdagi moment quyidagicha bo'ladi:

Impulsli bug 'turbinasi uchun: . Shuning uchun pichoqlar ustidagi tangensial kuch . Vaqt yoki quvvat birligida amalga oshirilgan ishlar: .

Ω turbinaning burchak tezligi bo'lsa, u holda pichoq tezligi bo'ladi . Rivojlangan kuch o'sha paytda .

Pichoq samaradorligi

Pichoq samaradorligi () pichoqlarda bajarilgan ishning suyuqlikka berilgan kinetik energiyaga nisbati sifatida aniqlanishi mumkin va quyidagicha berilgan

Sahna samaradorligi

Impulsli turbinaning bosqichi shtutser to'plami va harakatlanuvchi g'ildirakdan iborat. Sahna samaradorligi nozuladagi entalpi tushishi va bosqichda bajarilgan ishlar o'rtasidagi munosabatni belgilaydi.

Qaerda bug'ning o'ziga xos entalpiya tomchisi.

Tomonidan termodinamikaning birinchi qonuni:

Buni taxmin qilaylik ga nisbatan sezilarli darajada kamroq , biz olamiz . Bundan tashqari, sahna samaradorligi mahsulot pichoq samaradorligi va ko'krak samaradorligi yoki .

Nozzle samaradorligi tomonidan beriladi , bu erda nozulning kirish qismidagi bug'ning entalpiyasi (J / Kg da) va ko'krakdan chiqishda bug 'entalpiyasi .

Chiqish va kirish joyidagi pichoq burchaklari kosinuslarining nisbati olinishi va belgilanishi mumkin . Bug 'tezligining chiqishdagi rotor tezligiga nisbatan pichoqning kirish qismiga nisbati ishqalanish koeffitsienti bilan aniqlanadi .

va bug 'pichoqlar atrofida oqishi bilan ishqalanish natijasida nisbiy tezlikning yo'qolishini tasvirlaydi ( silliq pichoqlar uchun).

Pichoq tezligining kirishdagi absolyut bug 'tezligiga nisbati pichoq tezligi nisbati deb ataladi .

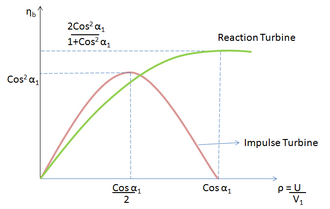

qachon maksimal bo'ladi yoki, . Bu shuni anglatadiki va shuning uchun . Endi (bitta bosqichli impuls turbinasi uchun).

Shuning uchun sahna samaradorligining maksimal qiymati, ning qiymatini qo'yish orqali olinadi ning ifodasida .

Biz olamiz: .

Teng burchakli pichoqlar uchun, , shuning uchun va biz olamiz . Agar pichoq yuzasi tufayli ishqalanish beparvo qilingan bo'lsa .

Maksimal samaradorlik bo'yicha xulosalar

- Bug'ning ma'lum bir tezligi uchun har bir kg bug 'uchun qilingan ish maksimal bo'lganda bo'ladi yoki .

- Sifatida ko'payadi, pichoqlarda bajarilgan ish kamayadi, lekin shu bilan birga pichoqning yuzasi kamayadi, shuning uchun ishqalanishdagi yo'qotishlar kamroq bo'ladi.

Reaksiya turbinalari

In reaktsiya turbinasi, rotor pichoqlar o'zlari konvergent hosil qilish uchun joylashtirilgan nozullar. Ushbu turdagi turbinalar hosil bo'lgan reaksiya kuchidan foydalanadi, chunki bug 'rotor tomonidan hosil bo'lgan nozullar orqali tezlashadi. Bug 'rotorga sobit qanotlari orqali yo'naltiriladi stator. Statorni rotorning butun atrofini to'ldiradigan reaktiv sifatida qoldiradi. Keyin bug 'yo'nalishini o'zgartiradi va pichoqlar tezligiga nisbatan tezligini oshiradi. Bosimning pasayishi statorda ham, rotorda ham ro'y beradi, bug'ning stator orqali tezlashishi va rotorda sekinlashishi bilan, sahna bo'ylab bug 'tezligi aniq o'zgarmasdan, lekin bosim va haroratning pasayishi bilan bajarilgan ishni aks ettiradi. rotorni boshqarish.

Pichoq samaradorligi

Bir bosqichda pichoqlarga energiya kiritish:

sobit pichoqlar bilan ta'minlangan kinetik energiyaga teng (f) + harakatlanuvchi pichoqlar bilan ta'minlangan kinetik energiya (m).

Yoki, = belgilangan pichoqlar ustiga entalpiya tushishi, + harakatlanuvchi pichoqlar ustiga entalpiya tushishi, .

Bug'ning harakatlanuvchi pichoqlar ustidan kengayishining ta'siri chiqishda nisbiy tezlikni oshirishga qaratilgan. Shuning uchun chiqishda nisbiy tezlik har doim kirishdagi nisbiy tezligidan katta .

Tezlik jihatidan harakatlanuvchi pichoqlar ustiga entalpi tushishi quyidagicha berilgan.

(bu statik bosimning o'zgarishiga yordam beradi)

Ruxsat etilgan pichoqlardagi entalpiyaning pasayishi, sobit pichoqlarga kiradigan bug'ning tezligi avval harakatlanuvchi pichoqlardan chiqib ketadigan bug'ning tezligiga teng degan taxmin bilan:

qaerda V0 bug'ning nozulga kirish tezligi

juda kichik va shuning uchun uni e'tiborsiz qoldirish mumkin. Shuning uchun,

Juda keng ishlatiladigan dizaynning yarmi bor reaktsiya darajasi yoki 50% reaktsiya va bu ma'lum Parson turbinasi. Bu nosimmetrik rotor va stator pichoqlaridan iborat. Ushbu turbinada tezlik uchburchagi o'xshash va bizda:

- ,

- ,

Faraz qiling Parson turbinasi va biz olgan barcha iboralarni olish

Kirish tezligi uchburchagidan bizda bor

Bajarilgan ishlar (sekundiga birlik massa oqimi uchun):

Shuning uchun pichoq samaradorligi tomonidan berilgan

Pichoqning maksimal samaradorligi holati

Agar , keyin

Maksimal samaradorlik uchun , biz olamiz

va bu nihoyat beradi

Shuning uchun, ning qiymatini qo'yish orqali topiladi pichoq samaradorligini ifodalashda

Foydalanish va texnik xizmat ko'rsatish

Bug 'zanjirlarida ishlatiladigan yuqori bosim va ishlatilgan materiallar tufayli bug' turbinalari va ularning korpuslari yuqori termal inertsiya. Bug 'turbinasini ishlatish uchun qizdirganda, asosiy bug' to'xtash vanalarida (qozondan keyin) o'ta qizib ketgan bug 'klapanni asta-sekin chetlab o'tishi va bug' turbinasi bilan birga tizimdagi chiziqlarni qizdirish uchun o'tish chizig'i mavjud. Shuningdek, a burilish moslamasi oldini olish uchun bir xil isitishni ta'minlash uchun turbinani asta-sekin aylantirish uchun bug 'yo'q bo'lganda ishlaydi notekis kengayish. Dastlab turbinani burilish moslamasi bilan aylantirgandan so'ng, rotorning tekis tekislikka o'tishiga vaqt berib (egilmasdan), keyin burilish moslamasi o'chiriladi va bug 'turbinaga, avval aster pichoqlariga, so'ngra old pichoqlarga sekin tushadi turbinani asta-sekin qizdirish uchun turbinani 10-15 min / min (0,17-0,25 gts) da aylantirish. Katta bug 'turbinalarini isitish tartibi o'n soatdan oshishi mumkin.[25]

Oddiy ishlash paytida rotor muvozanati tebranishga olib kelishi mumkin, bu esa aylanish tezligi yuqori bo'lgani uchun pichoqni rotordan va korpus orqali uzilishiga olib kelishi mumkin. Ushbu xavfni kamaytirish uchun turbinani muvozanatlash uchun katta kuch sarflanadi. Shuningdek, turbinalar yuqori sifatli bug 'bilan ishlaydi: yoki qizib ketgan (quruq) bug ', yoki to'yingan yuqori quruqlik fraktsiyasiga ega bug '. Bu pichoqlarga quyultirilgan suv portlatilganda (namlik o'tkazilganda) paydo bo'ladigan pichoqlarning tez urilib ketishini va eroziyasini oldini oladi. Bundan tashqari, pichoqlarga kiradigan suyuq suv turbina valining tortish rulmanlariga zarar etkazishi mumkin. Buning oldini olish uchun yuqori sifatli bug'ni ta'minlash uchun qozonlarda boshqaruv va to'siqlar bilan bir qatorda turbinaga olib boradigan bug 'quvurlariga kondensat drenajlari o'rnatiladi.

Zamonaviy bug 'turbinalarini texnik xizmat ko'rsatish talablari sodda va kam xarajatlarga olib keladi (odatda har bir kVt soatiga 0,005 dollar atrofida);[25] ularning ishlash muddati ko'pincha 50 yoshdan oshadi.[25]

Tezlikni tartibga solish

A bilan turbinani boshqarish hokim Bu juda muhim, chunki shikastlanishni oldini olish uchun turbinalar asta-sekin ishga tushirilishi kerak va ba'zi ilovalar (masalan, o'zgaruvchan tokni ishlab chiqarish) tezlikni aniq boshqarishni talab qiladi.[26] Turbinali rotorning nazoratsiz tezlashishi haddan tashqari tezlikni keltirib chiqarishi mumkin, bu esa turbinaga bug 'oqimini boshqaruvchi gubernator va gaz kelebeği vanalarining yopilishiga olib keladi. Agar ushbu klapanlar ishlamay qolsa, u holda turbin tez-tez katastrofik tarzda parchalanmaguncha tezlashishi mumkin. Turbinalarni tayyorlash qimmat, ularga aniq ishlab chiqarish va maxsus sifatli materiallar kerak.

Elektr tarmog'i bilan sinxronlashda normal ishlash vaqtida elektr stantsiyalari besh foiz bilan boshqariladi tezlikni boshqarish. Bu shuni anglatadiki, yukning to'liq tezligi 100% ni tashkil qiladi va yuklanishsiz tezligi 105% ni tashkil qiladi. Bu elektr stantsiyalarini ov qilmasdan va ishdan bo'shatmasdan tarmoqning barqaror ishlashi uchun talab qilinadi. Odatda tezlikning o'zgarishi unchalik katta emas. Quvvat chiqindilarini sozlash buloq bosimini a ga oshirib, egilish egri chizig'ini asta ko'tarish orqali amalga oshiriladi markazdan qochiruvchi gubernator. Umuman olganda, bu barcha elektr stantsiyalari uchun asosiy tizim talabidir, chunki eski va yangi qurilmalar tashqi aloqaga bog'liq bo'lmagan holda chastotaning bir zumda o'zgarishiga javoban mos kelishi kerak.[27]

Bug 'turbinalarining termodinamikasi

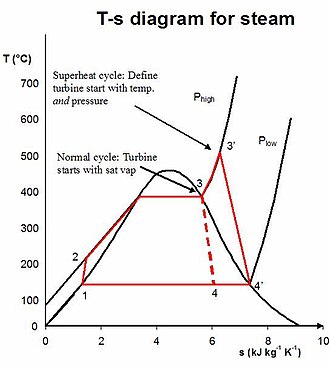

Bug 'turbinasi asosiy tamoyillari asosida ishlaydi termodinamika ning 3-4 qismidan foydalanib Rankin tsikli qo'shni diagrammada ko'rsatilgan. Juda qizib ketgan bug '(yoki qo'llanilishiga qarab quruq to'yingan bug') qozoni yuqori harorat va yuqori bosimda qoldiradi. Turbinaga kirishda bug 'nasadkadan o'tib kinetik energiyani oladi (impuls tipidagi turbinadagi sobit shtutser yoki reaksiya turbinasidagi turg'un pichoqlar). Bug 'nozuldan chiqib ketganda, turbinali rotorning pichoqlari tomon katta tezlikda harakatlanadi. Pichoqlar ustida bug 'bosimi tufayli ularning harakatlanishiga olib keladigan pichoqlar ustida kuch hosil bo'ladi. Jeneratör yoki shunga o'xshash boshqa moslama milga joylashtirilishi mumkin, va bug 'ichida bo'lgan energiya endi saqlanishi va ishlatilishi mumkin. Bug 'turbinani a shaklida qoldiradi to'yingan bug ' (yoki qo'llanilishiga qarab suyuqlik-bug 'aralashmasi) u bilan kiritilganidan pastroq harorat va bosim ostida va sovutish uchun kondensatorga yuboriladi.[28] Birinchi qonun, massa uchun ish tezligi formulasini topishga imkon beradi. Atrofdagi muhitga issiqlik uzatilmaydi va o'ziga xos o'zgarishga nisbatan kinetik va potentsial energiyaning o'zgarishi ahamiyatsiz deb hisoblasak. entalpiya biz quyidagi tenglamaga kelamiz

qayerda

- Ẇ vaqt birligiga ishning rivojlanish tezligi

- ṁ bu turbinadan o'tgan massa oqimining tezligi

Izentropik samaradorlik

Turbinaning qanchalik yaxshi ishlashini o'lchash uchun biz unga qarashimiz mumkin izentropik samaradorlik. Bu turbinaning haqiqiy ishlashini ideal, izentropik, turbinaning ishlashi bilan taqqoslaydi.[29] Ushbu samaradorlikni hisoblashda atrofga yo'qolgan issiqlik nolga teng deb qabul qilinadi. Bug 'boshlang'ich bosimi va harorati ham haqiqiy, ham ideal turbinalar uchun bir xil, ammo turbinadan chiqqanda, haqiqiy turbinada bug'ning energiya tarkibi ("o'ziga xos entalpiya") ideal turbinadan kattaroqdir, chunki haqiqiy turbinada qaytarilmasligi mumkin. . Ikkala o'rtasida yaxshi taqqoslash uchun o'ziga xos entalpiya haqiqiy va ideal turbinalar uchun bir xil bug 'bosimida baholanadi.

Izentropik samaradorlik haqiqiy ishni ideal ish bilan bo'lishish orqali topiladi.[29]

qayerda

- h3 bu uchinchi holatdagi o'ziga xos entalpiya

- h4 bu haqiqiy turbin uchun 4-holatdagi o'ziga xos entalpiya

- h4s izentropik turbin uchun 4s holatidagi o'ziga xos entalpiya

(lekin qo'shni diagrammada 4s holati ko'rinmasligini unutmang: u vertikal ravishda 3 holatidan pastda)

To'g'ridan-to'g'ri haydovchi

Elektr stantsiyalari katta bug 'turbinalarini haydashdan foydalaning elektr generatorlari dunyodagi elektr energiyasining katta qismini (taxminan 80%) ishlab chiqarish. Katta bug 'turbinalarining paydo bo'lishi markaziy elektr stantsiyasini ishlab chiqarishni amaliy holga keltirdi, chunki katta darajadagi pistonli bug' dvigatellari juda katta hajmga ega bo'lib, sekin tezlikda ishladilar. Aksariyat markaziy stantsiyalar qazilma yoqilg'i elektr stantsiyalari va atom elektr stantsiyalari; ba'zi o'rnatishlardan foydalaniladi geotermik bug 'yoki ishlating jamlangan quyosh energiyasi (CSP) bug 'hosil qilish uchun. Bug 'turbinalari to'g'ridan-to'g'ri katta haydash uchun ham ishlatilishi mumkin markazdan qochiradigan nasoslar, kabi ozuqa suv nasoslari a issiqlik elektr stantsiyasi.

The turbines used for electric power generation are most often directly coupled to their generators. As the generators must rotate at constant synchronous speeds according to the frequency of the electric power system, the most common speeds are 3,000 RPM for 50 Hz systems, and 3,600 RPM for 60 Hz systems. Since nuclear reactors have lower temperature limits than fossil-fired plants, with lower steam sifat, the turbine generator sets may be arranged to operate at half these speeds, but with four-pole generators, to reduce erosion of turbine blades.[30]

Dengiz harakatlanishi

Yilda paroxodlar, advantages of steam turbines over reciprocating engines are smaller size, lower maintenance, lighter weight, and lower vibration. A steam turbine is efficient only when operating in the thousands of RPM, while the most effective propeller designs are for speeds less than 300 RPM; consequently, precise (thus expensive) reduction gears are usually required, although numerous early ships through Birinchi jahon urushi, kabi Turbiniya, had direct drive from the steam turbines to the propeller shafts. Boshqa alternativa turbo-elektr uzatish, in which an electrical generator run by the high-speed turbine is used to run one or more slow-speed electric motors connected to the propeller shafts; precision gear cutting may be a production bottleneck during wartime. Turbo-electric drive was most used in large US warships designed during World War I and in some fast liners, and was used in some troop transports and mass-production halokat eskortlari yilda Ikkinchi jahon urushi.

The higher cost of turbines and the associated gears or generator/motor sets is offset by lower maintenance requirements and the smaller size of a turbine in comparison with a reciprocating engine of equal power, although the fuel costs are higher than those of a diesel engine because steam turbines have lower thermal efficiency. To reduce fuel costs the thermal efficiency of both types of engine have been improved over the years.

Dastlabki rivojlanish

The development of steam turbine marine propulsion from 1894 to 1935 was dominated by the need to reconcile the high efficient speed of the turbine with the low efficient speed (less than 300 rpm) of the ship's propeller at an overall cost competitive with pistonli dvigatellar. In 1894, efficient reduction tishli qutilar were not available for the high powers required by ships, so to'g'ridan-to'g'ri haydovchi zarur edi. Yilda Turbiniya, which has direct drive to each propeller shaft, the efficient speed of the turbine was reduced after initial trials by directing the steam flow through all three direct drive turbines (one on each shaft) in series, probably totaling around 200 turbine stages operating in series. Also, there were three propellers on each shaft for operation at high speeds.[31] The high shaft speeds of the era are represented by one of the first US turbine-powered yo'q qiluvchilar, USSSmit, launched in 1909, which had direct drive turbines and whose three shafts turned at 724 rpm at 28.35 knots (52.50 km/h; 32.62 mph).[32]

The use of turbines in several casings exhausting steam to each other in series became standard in most subsequent marine propulsion applications, and is a form of cross-compounding. The first turbine was called the high pressure (HP) turbine, the last turbine was the low pressure (LP) turbine, and any turbine in between was an intermediate pressure (IP) turbine. A much later arrangement than Turbiniya can be seen on RMSQirolicha Maryam yilda Long-Bich, Kaliforniya, launched in 1934, in which each shaft is powered by four turbines in series connected to the ends of the two input shafts of a single-reduction gearbox. They are the HP, 1st IP, 2nd IP, and LP turbines.

Cruising machinery and gearing

The quest for economy was even more important when cruising speeds were considered. Cruising speed is roughly 50% of a warship's maximum speed and 20-25% of its maximum power level. This would be a speed used on long voyages when fuel economy is desired. Although this brought the propeller speeds down to an efficient range, turbine efficiency was greatly reduced, and early turbine ships had poor cruising ranges. A solution that proved useful through most of the steam turbine propulsion era was the cruising turbine. This was an extra turbine to add even more stages, at first attached directly to one or more shafts, exhausting to a stage partway along the HP turbine, and not used at high speeds. As reduction gears became available around 1911, some ships, notably the jangovar kema USSNevada, had them on cruising turbines while retaining direct drive main turbines. Reduction gears allowed turbines to operate in their efficient range at a much higher speed than the shaft, but were expensive to manufacture.

Cruising turbines competed at first with reciprocating engines for fuel economy. An example of the retention of reciprocating engines on fast ships was the famous RMSTitanik of 1911, which along with her sisters RMSOlimpiya o'yinlari va HMHSBritanik had triple-expansion engines on the two outboard shafts, both exhausting to an LP turbine on the center shaft. After adopting turbines with the Delaver- sinf jangovar kemalari launched in 1909, the Amerika Qo'shma Shtatlari dengiz kuchlari reverted to reciprocating machinery on the Nyu York- sinf jangovar kemalari of 1912, then went back to turbines on Nevada in 1914. The lingering fondness for reciprocating machinery was because the US Navy had no plans for capital ships exceeding 21 knots (39 km/h; 24 mph) until after World War I, so top speed was less important than economical cruising. The United States had acquired the Filippinlar va Gavayi as territories in 1898, and lacked the British Qirollik floti 's worldwide network of ko'mir stantsiyalari. Thus, the US Navy in 1900–1940 had the greatest need of any nation for fuel economy, especially as the prospect of war with Yaponiya arose following World War I. This need was compounded by the US not launching any cruisers 1908–1920, so destroyers were required to perform long-range missions usually assigned to cruisers. So, various cruising solutions were fitted on US destroyers launched 1908–1916. These included small reciprocating engines and geared or ungeared cruising turbines on one or two shafts. However, once fully geared turbines proved economical in initial cost and fuel they were rapidly adopted, with cruising turbines also included on most ships. Beginning in 1915 all new Royal Navy destroyers had fully geared turbines, and the United States followed in 1917.

In Qirollik floti, speed was a priority until the Yutland jangi in mid-1916 showed that in the jangovar too much armour had been sacrificed in its pursuit. The British used exclusively turbine-powered warships from 1906. Because they recognized that a long cruising range would be desirable given their worldwide empire, some warships, notably the Qirolicha Yelizaveta- sinf jangovar kemalari, were fitted with cruising turbines from 1912 onwards following earlier experimental installations.

In the US Navy, the Mahan- sinfni yo'q qiluvchilar, launched 1935–36, introduced double-reduction gearing. This further increased the turbine speed above the shaft speed, allowing smaller turbines than single-reduction gearing. Steam pressures and temperatures were also increasing progressively, from 300 psi (2,100 kPa)/425 °F (218 °C) [saturated steam] on the World War I-era Viklar sinf to 615 psi (4,240 kPa)/850 °F (454 °C) [superheated steam] on some World War II Fletcher- sinfni yo'q qiluvchilar and later ships.[33][34] A standard configuration emerged of an axial-flow high-pressure turbine (sometimes with a cruising turbine attached) and a double-axial-flow low-pressure turbine connected to a double-reduction gearbox. This arrangement continued throughout the steam era in the US Navy and was also used in some Royal Navy designs.[35][36] Machinery of this configuration can be seen on many preserved World War II-era warships in several countries.[37]

When US Navy warship construction resumed in the early 1950s, most surface combatants and aircraft carriers used 1,200 psi (8,300 kPa)/950 °F (510 °C) steam.[38] This continued until the end of the US Navy steam-powered warship era with the Noks- sinf fregatlar 70-yillarning boshlarida. Amphibious and auxiliary ships continued to use 600 psi (4,100 kPa) steam post-World War II, with USSIvo Jima, launched in 2001, possibly the last non-nuclear steam-powered ship built for the US Navy.

Turbo-elektr haydovchi

Turbo-elektr haydovchi was introduced on the battleship USSNyu-Meksiko, launched in 1917. Over the next eight years the US Navy launched five additional turbo-electric-powered battleships and two aircraft carriers (initially ordered as Leksington- sinf jangovar kemalari ). Ten more turbo-electric capital ships were planned, but cancelled due to the limits imposed by the Vashington dengiz shartnomasi.

Garchi Nyu-Meksiko was refitted with geared turbines in a 1931–1933 refit, the remaining turbo-electric ships retained the system throughout their careers. This system used two large steam turbine generators to drive an electric motor on each of four shafts. The system was less costly initially than reduction gears and made the ships more maneuverable in port, with the shafts able to reverse rapidly and deliver more reverse power than with most geared systems.

Some ocean liners were also built with turbo-electric drive, as were some troop transports and mass-production halokat eskortlari yilda Ikkinchi jahon urushi. However, when the US designed the "treaty cruisers", beginning with USSPensakola launched in 1927, geared turbines were used to conserve weight, and remained in use for all fast steam-powered ships thereafter.

Joriy foydalanish

Since the 1980s, steam turbines have been replaced by gaz turbinalari on fast ships and by dizel dvigatellari on other ships; exceptions are nuclear-powered ships and submarines va LNG tashuvchilar.[39] Biroz yordamchi kemalar continue to use steam propulsion.

In the U.S. Navy, the conventionally powered steam turbine is still in use on all but one of the Wasp-class amphibious assault ships. The Qirollik floti decommissioned its last conventional steam-powered surface warship class, the Qo'rqmas- sinf landing platform dock, in 2002, with the Italiya dengiz floti following in 2006 by decommissioning its last conventional steam-powered surface warships, the Audace- sinf yo'q qiluvchilar. 2013 yilda, Frantsiya dengiz floti ended its steam era with the decommissioning of its last Tourville- sinf frekat. Boshqalar orasida ko'k-dengiz flotlari, the Russian Navy currently operates steam-powered Kuznetsov- sinf samolyot tashuvchilar va Sovremenny- sinf yo'q qiluvchilar. The Hindiston dengiz floti currently operates INS Vikramaditya, o'zgartirilgan Kiev- sinf samolyot tashuvchisi; it also operates three Braxmaputra- sinf fregatlar commissioned in the early 2000s and one Godavari- sinf frekat scheduled for decommissioning. The Chinese Navy currently operates steam-powered Kuznetsov- sinf samolyot tashuvchilar, Sovremenny- sinf yo'q qiluvchilar bilan birga Luda- sinf yo'q qiluvchilar va yolg'iz 051B tipidagi qiruvchi. Most other naval forces either retired or re-engined their steam-powered warships by 2010. As of 2020, the Meksika dengiz floti operates four steam-powered former U.S. Noks- sinf frekat and two steam-powered former U.S. Bronshteyn- sinf frekat. The Misr dengiz floti va Xitoy Respublikasi Dengiz kuchlari respectively operate two and six former U.S. Noks- sinf fregatlar. The Ekvador dengiz kuchlari currently operates two steam-powered Kondell- sinf fregatlar (o'zgartirilgan) Leander- sinf fregatlar ).

Today, propulsion steam turbine cycle efficiencies have yet to break 50%, yet diesel engines routinely exceed 50%, especially in marine applications.[40][41][42] Diesel power plants also have lower operating costs since fewer operators are required. Thus, conventional steam power is used in very few new ships. Istisno LNG tashuvchilar which often find it more economical to use boil-off gas with a steam turbine than to re-liquify it.

Nuclear-powered ships and submarines use a nuclear reactor to create steam for turbines. Nuclear power is often chosen where diesel power would be impractical (as in dengiz osti kemasi applications) or the logistics of refuelling pose significant problems (for example, muzqaymoq ). It has been estimated that the reactor fuel for the Qirollik floti "s Avangard- sinf osti kemalari is sufficient to last 40 circumnavigations of the globe – potentially sufficient for the vessel's entire service life. Nuclear propulsion has only been applied to a very few savdo kemalar due to the expense of maintenance and the regulatory controls required on nuclear systems and fuel cycles.

Lokomotivlar

A steam turbine locomotive engine is a parovoz driven by a steam turbine. The first steam turbine rail locomotive was built in 1908 for the Officine Meccaniche Miani Silvestri Grodona Comi, Milan, Italy. 1924 yilda Krupp built the steam turbine locomotive T18 001, operational in 1929, for Deutsche Reichsbahn.

The main advantages of a steam turbine locomotive are better rotational balance and reduced bolg'a zarbasi yo'lda. However, a disadvantage is less flexible output power so that turbine locomotives were best suited for long-haul operations at a constant output power.[43]

Sinov

British, German, other national and international test codes are used to standardize the procedures and definitions used to test steam turbines. Selection of the test code to be used is an agreement between the purchaser and the manufacturer, and has some significance to the design of the turbine and associated systems.

Qo'shma Shtatlarda, MENDEK has produced several performance test codes on steam turbines. These include ASME PTC 6–2004, Steam Turbines, ASME PTC 6.2-2011, Steam Turbines in Combined Cycles, PTC 6S-1988, Procedures for Routine Performance Test of Steam Turbines. These ASME performance test codes have gained international recognition and acceptance for testing steam turbines. The single most important and differentiating characteristic of ASME performance test codes, including PTC 6, is that the test uncertainty of the measurement indicates the quality of the test and is not to be used as a commercial tolerance.[44]

Shuningdek qarang

Adabiyotlar

Izohlar

- ^ Stodola 1927.

- ^ "Ser Charlz Aljernon Parsons". Britannica entsiklopediyasi. nd. Olingan 2010-09-19.

- ^ "Electricity Net Generation" (PDF). US EIA. 2015 yil mart.

- ^ Keyser 1992, pp. 107-124.

- ^ O'Connor & Robertson 1999.

- ^ Nag 2002, pp. 432–.

- ^ "Taqi al-Din and the First Steam Turbine, 1551 A.D." Islomdagi fan va texnika tarixi. Arxivlandi asl nusxasi on 2008-02-18.

- ^ Hassan 1976, p. 34-35.

- ^ "James Watt". www.steamindex.com. Arxivlandi asl nusxasidan 2017-09-06.

- ^ Stodola & Loewenstein 1945.

- ^ a b Bug 'turbinasi da Orqaga qaytish mashinasi (arxivlangan 2010 yil 13 may)

- ^ Charlz Parsons da Orqaga qaytish mashinasi (archived May 5, 2010)

- ^ Parsons 1911.

- ^ Giampaolo 2014, p. 9.

- ^ Stodola 2013.

- ^ a b Capital Goods: China Losing Its Shine da Orqaga qaytish mashinasi (archived December 23, 2015)

- ^ Bayar 2014.

- ^ Parsons 1911, 7-8 betlar.

- ^ Parsons 1911, 20-22 betlar.

- ^ Parsons 1911, 23-25 betlar.

- ^ Tamarin 2002, p. 5–.

- ^ Bhadeshia 2003.

- ^ Latief & Kakehi 2013.

- ^ "Steam Turbines (Course No. M-3006)" (PDF). PhD Engineer. Arxivlandi (PDF) asl nusxasidan 2012-04-02. Olingan 2011-09-22.

- ^ a b v "Technology Characterization: Steam Turbines" (PDF). AQSh atrof-muhitni muhofaza qilish agentligi. Dekabr 2008. p. 13. Arxivlangan asl nusxasi (PDF) 2012 yil 18-noyabrda. Olingan 25 fevral 2013.

- ^ Whitaker 2006, p. 35.

- ^ "Speed Droop and Power Generation. Application Note 01302" (pdf). Vudvord. 1991 yil.

- ^ "Thermodynamics Steam Turbine". www.roymech.co.uk. Arxivlandi from the original on 2011-01-08.

- ^ a b Moran et al. 2010 yil.

- ^ Leyzerovich 2005, p. 111.

- ^ Parsons 1911, 26-31 betlar.

- ^ Fridman 2004 yil, p. 23-24.

- ^ "1,500-ton destroyers in World War II". destroyerhistory.org. Arxivlandi from the original on 2013-11-05.

- ^ Fridman 2004 yil, p. 472.

- ^ Bowie 2010.

- ^ "Steam Turbines". www.leander-project.homecall.co.uk. Arxivlandi from the original on 2013-11-22.

- ^ "Historic Naval Ships Association". Arxivlandi asl nusxasi on 2013-06-22.

- ^ Fridman 2004 yil, p. 477.

- ^ "Mitsubishi Heavy starts construction of first Sayaendo series LNG carrier". 2012 yil dekabr. Arxivlandi from the original on 2014-08-07.

- ^ Deckers 2003, p. 14-15.

- ^ Leyzerovich 2002.

- ^ Takaishi, Tatsuo; Numata, Akira; Nakano, Ryouji; Sakaguchi, Katsuhiko (March 2008). "Approach to High Efficiency Diesel and Gas Engines" (PDF). Texnik ko'rib chiqish. Mitsubishi Heavy Industries. Olingan 6 may 2019.

- ^ Streeter 2007, p. 85.

- ^ Sanders 2004 yil, p. 292.

Manbalar

- Bayar, Tildy (July 31, 2014). "Global gas and steam turbine market to reach $43.5bn by 2020". Power Engineering International.

- Bhadeshia, H. K. D. H. (2003). "Nikel asosidagi superalloyimalar". Kembrij universiteti. Olingan 2008-09-04.

- Bowie, David (2010). "Cruising Turbines of the Y-100 Naval Propulsion Machinery" (PDF).

- Deckers, Matthias (Summer 2003). "CFX Aids Design of World's Most Efficient Steam Turbine" (PDF). CFXUpdate (23). Arxivlandi asl nusxasi (PDF) on 2005-10-24.

- Giampaolo, Tony (2014). Gas Turbine Handbook Principles and Practices By Tony Giampaolo: Gas Turbine Handbook. Digital Designs.

- Fridman, Norman (2004). AQSh halokatlari: Tasvirlangan dizayn tarixi. Annapolis: dengiz instituti matbuoti. ISBN 978-1-55750-442-5.

- Xasan, Ahmad Y (1976). Taqi al-Din and Arabic Mechanical Engineering. Arab ilmi tarixi instituti, Aleppo universiteti.

- Keyser, Paul (1992). "A new look at Heron's Steam Engine". Aniq fanlar tarixi arxivi. 44 (2): 107–124. doi:10.1007/BF00374742. ISSN 0003-9519.

- Latief, Fahamsyah H.; Kakehi, Koji (2013). "Effects of Re content and crystallographic orientation on creep behavior of aluminized Ni-base single crystal superalloys". Materiallar va dizayn. 49: 485–492. doi:10.1016/j.matdes.2013.01.022. ISSN 0261-3069.

- Leyzerovich, Alexander S. (August 1, 2002). "New Benchmarks for Steam Turbine Efficiency". Energetika. Arxivlandi asl nusxasi 2009-09-18. Olingan 2010-09-12.

- Leyzerovich, Alexander (2005). Wet-steam Turbines for Nuclear Power Plants. PennWell kitoblari. ISBN 978-1-59370-032-4.

- Moran, Maykl J.; Shapiro, Howard N.; Boettner, Daisie D.; Bailey, Margaret B. (2010). Fundamentals of Engineering Thermodynamics. John Wiley & Sons. ISBN 978-0-470-49590-2.

- Nag, P. K. (2002). Power Plant Engineering. Tata McGraw-Hill ta'limi. ISBN 978-0-07-043599-5.

- Parsons, Charlz A. (1911). . University Press, Cambridge.

- O'Konnor, JJ .; Robertson, E.F. (1999). "Heron of Alexandria". The MacTutor History of Mathematics.

- Sanders, William P. (2004). Turbine Steam Path: Mechanical Design and Manufacture. Vol. III a. PennWell.

- Stodola, A. (2013) [1924]. Dampf- und Gasturbinen. Mit einem Anhang über die Aussichten der Wärmekraftmaschinen [Steam and Gas Turbines: With an appendix on the prospective use as heat engines] (in German) (Supplement to the 5th ed.). Springer-Verlag. ISBN 978-3-642-50854-7.

- Stodola, Aurel (1927). Steam and Gas Turbines: With a Supplement on The Prospects of the Thermal Prime Mover. McGraw-Hill.

- Stodola, Aurel; Loewenstein, Louis Centennial (1945). Steam and gas turbines: with a supplement on The prospects of the thermal prime mover. P. Smit.

- Streeter, Tony (2007). "Testing the Limit". Buxoriy temir yo'l jurnali (336).

- Tamarin, Y. (2002). Protective Coatings for Turbine Blades. ASM International. ISBN 978-1-61503-070-5.

- Whitaker, Jerry C. (2006). AC Power Systems Handbook (Uchinchi nashr). Teylor va Frensis. ISBN 978-0-8493-4034-5.

Qo'shimcha o'qish

- Cotton, K.C. (1998). Evaluating and Improving Steam Turbine Performance.

- Johnston, Ian (2019). "The Rise of the Brown-Curtis Turbine". Iordaniyada Jon (tahr.) Harbiy kema 2019. Oksford, Buyuk Britaniya: Osprey nashriyoti. 58-68 betlar. ISBN 978-1-4728-3595-6.

- Traupel, W. (1977). Thermische Turbomaschinen (nemis tilida).

- Thurston, R. H. (1878). A History of the Growth of the Steam Engine. D. Appleton va Co.

- Waliullah, Noushad (2017). "An overview of Concentrated Solar Power (CSP) technologies and its opportunities in Bangladesh". 2017 International Conference on Electrical, Computer and Communication Engineering (ECCE). CUET. pp. 844–849. doi:10.1109/ECACE.2017.7913020. ISBN 978-1-5090-5627-9.

Tashqi havolalar

- Steam Turbines: A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime Movers by Hubert E. Collins

- Steam Turbine Construction at Mike's Engineering Wonders

- Tutorial: "Superheated Steam"

- Flow Phenomenon in Steam Turbine Disk-Stator Cavities Channeled by Balance Holes

- Guide to the Test of a 100 K.W. De Laval Steam Turbine with an Introduction on the Principles of Design taxminan 1920 yil

- Extreme Steam- Unusual Variations on The Steam Locomotive

- Interactive Simulation of 350MW Steam Turbine with Boiler developed by Kvinslend universiteti, in Brisbane Australia

- "Super-Steam...An Amazing Story of Achievement" Mashhur mexanika, August 1937

- Modern Energetics - The Steam Turbine