Madaniy go'sht - Cultured meat

Madaniy go'sht tomonidan ishlab chiqarilgan go'sht hisoblanadi in vitro hujayra madaniyati dan o'rniga hayvon hujayralari so'yilgan hayvonlar.[1] Bu shakl uyali qishloq xo'jaligi.

Madaniy go'sht bir xil turdagi go'shtlardan foydalanib ishlab chiqariladi to'qima muhandisligi an'anaviy ravishda ishlatiladigan texnika regenerativ tibbiyot.[2] Madaniy go'sht tushunchasi tomonidan ommalashtirildi Jeyson Mateni 2000-yillarning boshlarida hammualliflik qilganidan keyin a seminal qog'oz[3] madaniy go'sht ishlab chiqarish va yaratish bo'yicha Yangi hosil, qo'llab-quvvatlashga bag'ishlangan dunyodagi birinchi notijorat tashkilot in vitro go'sht tadqiqotlari.[4]

2013 yilda, Mark Post, professor Maastrixt universiteti, to'g'ridan-to'g'ri hujayralardan o'stirilgan birinchi burger pattasini yaratib, madaniy go'sht uchun kontseptsiyani birinchi bo'lib namoyish etdi. O'shandan beri bir nechta madaniy go'sht prototiplari ommaviy axborot vositalarining e'tiboriga sazovor bo'ldi: Madaniy go'shtga xizmat ko'rsatadigan birinchi restoran Isroilda.[5][6]

Ishlab chiqarish jarayoni hali ham takomillashtirish uchun juda ko'p imkoniyatlarga ega, ammo u turli kompaniyalar ostida rivojlangan.[7] Uning qo'llanmalari odatdagi go'sht bilan taqqoslaganda bir nechta istiqbolli axloqiy, sog'liqni saqlash, ekologik, madaniy va iqtisodiy jihatlarga ega bo'lishiga olib keladi.[8]

Nomenklatura

Bundan tashqari madaniy go'sht, shartlar sog'lom go'sht,[9] so'yishsiz go'sht,[10] in vitro go'sht, QQS o'sgan,[11] laboratoriyada etishtirilgan go'sht,[12] hujayralarga asoslangan go'sht,[13] toza go'sht,[14] etishtirilgan go'sht[15] va sintetik go'sht[16] barchasi mahsulotni tavsiflash uchun turli xil savdo shoxobchalari tomonidan ishlatilgan.

2016 va 2019 o'rtasida, toza go'sht texnologiyani qo'llab-quvvatlaydigan ba'zi jurnalistlar, advokatlar va tashkilotlar tomonidan ma'qul bo'lgan atama sifatida jalb qilindi. Yaxshi ovqat instituti (GFI) bu atamani 2016 yilda kiritgan,[17] va 2018 yil oxirida chop etilgan tadqiqotlar natijalariga ko'ra "toza" go'shtning ishlab chiqarilishi va foydasi yaxshiroq aks etgan[18][19] va "madaniyatli" va "in vitro"ommaviy axborot vositalarida va Google qidiruvlarida.[20] Shunga qaramay, ba'zi bir sanoat manfaatdor tomonlari bu atama an'anaviy go'sht ishlab chiqaruvchilarni afzal ko'rishni davom ettirishni keraksiz ravishda begonalashtirgan deb hisoblashdi hujayralarga asoslangan go'sht neytral alternativa sifatida.[21][22]

2019 yil sentyabr oyida GFI yangi tadqiqotlarni e'lon qildi, natijada ushbu atama aniqlandi etishtirilgan go'sht etarlicha tavsiflovchi va farqlovchi, yuqori betaraflikka ega va iste'molchilarning murojaatlari uchun yuqori o'rinlarni egallaydi.[15][23]

Tarix

Dastlabki tadqiqotlar

Sanoat sharoitida go'sht etishtirishning nazariy imkoniyati uzoq vaqt jamoatchilik tasavvurini egallab olgan. 1931 yil "Ellik yil" inshoida, Uinston Cherchill shunday deb yozgan edi: "Biz bu qismlarni mos muhit ostida alohida-alohida o'stirib, ko'krak yoki qanotni eyish uchun butun bir tovuqni o'stirish bema'nilikdan qutulamiz".[24]

1950-yillarda gollandiyalik olim Uilyam Van Eelen madaniy go'sht uchun g'oyani mustaqil ravishda ilgari surdi. Ikkinchi jahon urushi paytida bolaligida Van Eelen ochlikdan azob chekdi, chunki u kattalar paytida uni oziq-ovqat ishlab chiqarish va oziq-ovqat xavfsizligi bilan shug'ullanishga undadi. U talaba sifatida Amsterdam universitetida qatnashgan va bir vaqtning o'zida saqlanib qolgan go'shtning istiqbollarini muhokama qilgan ma'ruzada qatnashgan. Asrning boshida hujayra chiziqlarini kashf etish bilan birga, bu etishtirilgan go'shtning sezgi sezgisini qo'zg'atdi.

In vitro etishtirish mushak tolalari birinchi bo'lib 1971 yilda Rassel Ross madaniyatli bo'lganida muvaffaqiyatli ijro etilgan dengiz cho'chqasi aorta. U o'z maqolasining tezisida "etuk bo'lmagan dengiz cho'chqalari aortasining ichki muhitidan va intimasidan olingan silliq mushak 8 xaftaga qadar o'sgan", deb ta'kidladi. hujayra madaniyati. Hujayralar o'sishining barcha bosqichlarida silliq mushaklarning morfologiyasini saqlab qolishdi. Uyg'unlashib ketgandan so'ng, ular bir-birining ustiga o'ralgan qatlamlarda o'sdi. Madaniyatning 4-haftasida hujayralar qatlamlari orasidagi bo'shliqlarda mikrofibrillalar (110 A) paydo bo'ldi. Poydevor membranasi o'xshash material ham hujayralarga qo'shni bo'lib paydo bo'ldi. Mikrofibrillalarning tahlili shuni ko'rsatdiki, ular buzilmagan elastik tolaning mikrofibrillar oqsiliga o'xshash aminokislota tarkibiga ega. Ushbu tergovlar bilan radioavtografik aorta silliq mushaklarining hujayradan tashqari oqsillarni sintez qilish va ajratish qobiliyatini kuzatishlar bu hujayraning biriktiruvchi to'qima sintetik hujayrasi ekanligini ko'rsatmoqda ".[25]

1991 yilda Amerika Qo'shma Shtatlaridan Jon F. Vein inson iste'mol qilish uchun to'qimalarda ishlab chiqarilgan go'sht ishlab chiqarish uchun patentni (6,835,390 B1 AQSh) topshirdi va natijada kafolatlandi, bu erda mushak va yog 'hujayralari birlashtirilgan holda o'stirilishi kerak edi. mol go'shti, parrandachilik va baliq kabi oziq-ovqat mahsulotlari.[25]

2001 yilda, dermatolog Wiete Westerhof Amsterdam universiteti, tibbiyot shifokori Villem van Eelen va tadbirkor Villem van Kooten butun dunyo bo'ylab ariza topshirganliklarini e'lon qilishdi Patent madaniy go'sht ishlab chiqarish jarayoni to'g'risida.[26] Bu jarayonda, a matritsa ning kollagen bilan urug'langan muskul hujayralar, keyin ular to'yimli eritmada yuviladi va bo'linishga undaydi[27]

O'sha yili NASA madaniy go'shtda tajribalarni o'tkazib, uni kosmik sayohatga tatbiq etish maqsadida uzoq muddatli astronavtlarga sayohatni saqlashdan voz kechmasdan go'sht etishtirishga imkon berdi. Turro kolleji xodimi Morris Benjaminson bilan hamkorlikda ular oltin baliq to'qimalarining segmentlarini va keyinchalik kurka hujayralarini o'stirishga muvaffaq bo'lishdi.[28]

2003 yilda, Oron mushuklari va Ionat Zurr To'qimalarning madaniyati va san'ati loyihasining va Garvard tibbiyot maktabi namoyish etildi Nant quritilgan qurbaqa ildiz hujayralaridan o'stirilgan, eni bir necha santimetr bo'lgan "biftek". U ko'rgazmaning maqsadi madaniy go'sht axloqi bo'yicha suhbatni boshlash edi - u tirikmi, o'ldiriladimi? uni tashlash har qanday yo'l bilan hayvonga nisbatan hurmatsizlikmi?[29]

2000-yillarning boshlarida amerikalik sog'liqni saqlash talabasi Jeyson Mateni Hindistonga sayohat qildi va tovuq fabrikasi fermasiga tashrif buyurdi. Jamiyat salomatligi nuqtai nazaridan u ushbu tizimning inson iste'molchilari uchun ta'siridan dahshatga tushdi. Matheny Qo'shma Shtatlarga qaytib kelgach, NASAning go'shtni madaniylashtirish bo'yicha harakatlarida ishtirok etgan 3 olim bilan birlashdi. To'rttasi laboratoriya asosida tayyorlangan go'shtning tijorat istiqbollari bo'yicha tadqiqotlarni boshladilar va keyinchalik ularning topilmalari 2005 yilda "Tissue Engineering" da nashr etilgan bo'lib, ushbu mavzu bo'yicha birinchi bo'lib ko'rib chiqilgan adabiyot edi. 2004 yilda, Matheny, shuningdek, jamoat tadqiqotlarini moliyalashtirish orqali sohada rivojlanishni rag'batlantirishni maqsad qilgan yangi hosilni yaratdi.[30]

2008 yilda, PETA laboratoriyada etishtirilgan tovuq go'shtini iste'molchilarga 2012 yilgacha etkazib beradigan birinchi kompaniyaga 1 million dollar mukofot taklif qildi.[31] Musobaqa ishtirokchisi sovrinni olishdan oldin ikkita vazifani bajarishi kerak edi: "Haqiqiy tovuq go'shtidan ajratib bo'lmaydigan madaniy tovuq go'shti mahsulotini ishlab chiqarish" va "Kamida 10 shtatda raqobatbardosh sotilishi uchun mahsulotni yetarlicha ko'p miqdorda ishlab chiqarish". Tanlov 2014 yil 4 martgacha uzaytirildi. Birinchi marta e'lon qilingan 2008 yildan buyon butun dunyodagi tadqiqotchilar madaniy go'sht ishlab chiqarishda katta yutuqlarga erishdilar. Belgilangan muddat g'olibsiz yakunlandi, ammo bu mavzu atrofidagi reklama madaniy go'shtni olimlar e'tiboriga yanada ko'proq jalb qildi.[32]

2008 yilda Gollandiya hukumati madaniy go'sht bo'yicha tajribalarga 4 million dollar sarmoya kiritdi.[33] Texnologiyaga qiziquvchi xalqaro tadqiqotchilar tomonidan tashkil etilgan In Vitro Meat Consortium guruhi madaniy go'sht ishlab chiqarish bo'yicha birinchi xalqaro konferentsiyani o'tkazdi. Oziq-ovqat tadqiqot instituti ning Norvegiya tijorat imkoniyatlarini muhokama qilish uchun 2008 yil aprel oyida.[34]Vaqt jurnali madaniy go'sht ishlab chiqarishni 2009 yilgi 50 ta g'oyadan biri deb e'lon qildi.[35]

2009 yil noyabr oyida Niderlandiyalik olimlar laboratoriyada tirik cho'chqaning hujayralari yordamida go'sht etishtirishga muvaffaq bo'lganliklarini e'lon qilishdi.[36]

Birinchi ommaviy sud

Birinchi o'stirilgan mol go'shti burger patti doktor tomonidan yaratilgan. Mark Post da Maastrixt universiteti 2013 yilda.[37] U mushak to'qimalarining 20000 dan ortiq ingichka iplaridan tayyorlangan., Qiymati Doktor Post ishlab chiqarish uchun $ 300,000 dan ortiq va ishlab chiqarish uchun 2 yil ichida.[38] O'shandan beri taxmin qilinishicha, narx 2021 yilga kelib 10 dollarga tushishi mumkin.[39]

Burger 2013 yil 5 avgustda Londonda jonli televizorda sinovdan o'tkazildi. Uni Couchning Great House restoranining bosh oshpazi Richard McGeown pishirdi, Polperro, Cornwall va tanqidchilar tomonidan tatib ko'rilgan Xanni Rutzler, Future Food Studio-dan oziq-ovqat tadqiqotchisi va Josh Shonvald. Rutzler shunday dedi: “Haqiqatan ham bu erda tishlash bor, jigarrang rangda lazzat bor. Men u erda yog 'yo'qligini bilaman, shuning uchun uning qanchalik shirali bo'lishini bilmasdim, ammo juda qattiq ta'mi bor; u go'shtga yaqin, u suvli emas, lekin qat'iylik juda yaxshi. Bu menga go'sht ... Bu chindan ham tishlash kerak bo'lgan narsa va menimcha, qiyofasi juda o'xshash. "Rutzler qo'shib qo'ydi ko'r sud u mahsulotni o'rniga go'sht uchun olgan bo'lar edi soya nusxasi.[40]

Sanoatni rivojlantirish

- Piter Verstrat, Mosa go'shti (2018)[41](1:06:15)

2011 va 2017 yillar orasida ko'plab madaniy go'sht ishlab chiqarish bo'yicha startaplar ishga tushirildi. Memfis go'shtlari, kardiolog tomonidan tashkil etilgan Silikon vodiysidagi startap, 2016 yil fevral oyida o'zining madaniy go'shtli go'shtini namoyish etgan videoni namoyish etdi.[42][43][44] 2017 yil mart oyida u tovuq go'shti tenderlarini namoyish etdi va jamoat uchun namoyish etilgan parranda go'shti asosida ishlab chiqarilgan birinchi oziq-ovqat mahsuloti.[45][46][47] Keyinchalik Memfis Meats 2020 yilda "Kelajak go'shti" hujjatli filmining mavzusi bo'ldi.

Isroil kompaniyasi, SuperMeat, 2016 yilda madaniy tovuq bo'yicha ishi uchun virusli kraudfanding kampaniyasini o'tkazdi.[48][49][50][51][52]

San-Fransiskoda joylashgan madaniy baliqlarga ixtisoslashgan Finless Foods kompaniyasi 2016 yil iyun oyida tashkil etilgan. 2017 yil mart oyida u laboratoriya ishlarini boshladi va tez rivojlandi. Direktor Mayk Selden 2017 yil iyul oyida ikki yil ichida (2019 yil oxiriga qadar) madaniy baliq mahsulotlarini bozorga chiqarishni kutishini aytdi.[53]

2018 yil mart oyida, Faqat ovqatlaning (2011 yilda San-Frantsiskoda Xempton Kriki sifatida tashkil etilgan, keyinchalik "Just, Inc." nomi bilan tanilgan) 2018 yil oxiriga qadar iste'mol qilingan mahsulotni madaniy go'shtdan taqdim eta olamiz deb da'vo qilmoqda. Bosh direktorning so'zlariga ko'ra Josh Tetrik texnologiya allaqachon mavjud va endi bu shunchaki uni qo'llash bilan bog'liq. JUSTda 130 ga yaqin xodim va 55 ta olimning tadqiqot bo'limi mavjud bo'lib, u erda parranda, cho'chqa go'shti va mol go'shtidan laboratoriya go'shti ishlab chiqilmoqda. Ildiz hujayralarini faqat o'simlik resurslari bilan boqish masalasini ular allaqachon hal qilishgan bo'lar edi. JUST xitoylik milliarderdan homiylik oladi Li Ka-shing, Yahoo! hammuassisi Jerri Yang va Tetrickning so'zlariga ko'ra Heineken International boshqalar qatorida.[54]

- Krijn de Nood, go'shtli (2020)[55]

Krijn de Nod, Daan Luining, Ruud Out, Rojer Pederson, Mark Kotter va Gordana Apich va boshqalardan iborat Gollandiyaning Meatable startapi 2018 yil sentyabr oyida hayvonlardan pluripotent ildiz hujayralari yordamida go'sht etishtirishga muvaffaq bo'lganligi haqida xabar berdi. kindik ichakchalari. Xabar qilinishicha, bunday hujayralar bilan ishlash qiyin bo'lsa ham, Meatable ularni mushak hujayralari yoki kerak bo'lganda yog 'hujayralari bo'lishlari uchun ularni o'zlarining texnikalaridan foydalangan holda boshqarishga qodir deb da'vo qilmoqda. Asosiy afzallik shundaki, ushbu texnikani chetlab o'tish xomilalik sigir zardobi, ya'ni go'sht ishlab chiqarish uchun hech qanday hayvonni o'ldirish shart emas.[56] O'sha oyda butun dunyoda 30 ga yaqin madaniy go'shtni ishga tushirish bo'yicha startaplar borligi taxmin qilingan. Gollandiyalik Vakillar palatasi Komissiya yig'ilishida 2018 yil 26 sentyabrda uchta universitet, uchta startap va to'rtta fuqarolik manfaatlari guruhlari vakillari oldida nutq so'zlab, madaniy go'shtni tadqiq etish, rivojlantirish va jamiyatda joriy etish bo'yicha davlat ko'magi muhimligi va zarurligi muhokama qilindi.[41]

Integ Agricultureure - bu Yaponiyada joylashgan va CulNet tizimi orqali hujayralarni hayvonlarga asoslangan zardobli qo'shimchalarsiz ko'paytirishga imkon beradigan madaniyat tizimini yaratish ustida ish olib boruvchi kompaniya. Xuddi shu muammo ustida ishlaydigan kompaniyalar qatoriga Angliyada joylashgan Multus Media va Kanadadagi Future Fields kiradi.[iqtibos kerak ]

2019 yil avgust oyida beshta boshlang'ich tashkilot go'sht, parrandachilik va dengiz mahsulotlari uchun innovatsiyalar alyansi (AMPS Innovation) tashkil etilganligini e'lon qildi, bu madaniy go'sht va dengiz maxsulotlari bozoriga yo'l ochish uchun hukumat regulyatorlari bilan ishlashni istaydi.[57] Ta'sischi a'zolar kiradi Faqat ovqatlaning, Memfis go'shtlari, Finless Foods, BlueNalu va Fork & Goode.[58]

2019 yilda Foieture loyihasi boshlandi Belgiya madaniyatli rivojlanish maqsadida Fuagra (nomi "foie" va "kelajak" portmantoni) 3 ta konsortsium tomonidan (go'shtli go'shtni ishga tushirish bo'yicha tinchlik, kichik go'sht -ziravor Solina kompaniyasi va kichik pate - ishlab chiqaruvchi kompaniya Nauta) va 3 ta notijorat institut (universitet) KU Leuven, oziq-ovqat sanoatining innovatsion markazi Flanders Food va Bio Base Europe Pilot Plant).[59] Boshqalarning yordami bilan "Go'shtning tinchligi" 2019 yil dekabrda o'zining kontseptsiyasini 2020 yilda to'ldirishga, 2022 yilda birinchi prototipini ishlab chiqarishga va 2023 yilda bozorga chiqishga intilishini aytdi.[59] O'sha oy Foieture loyihasi Innovatsiyalar va korxonalar agentligidan qariyb 3,6 million evro miqdorida ilmiy grant oldi. Flamand hukumati.[59] 2020 yil may oyida "Peace of Meat" ning Avstriyada tug'ilgan asoschisi va ilmiy tadqiqotchisi Eva Sommerning ta'kidlashicha, startap keyinchalik 300 gramm (15000 evro / kg) ga teng 20 gramm madaniy yog 'ishlab chiqarishga qodir; Maqsad 2030 yilgacha kilogramm narxi 6 evrogacha tushirish edi.[60] Parcha go'sht yaqinda ikkita laboratoriyani quradi Antverpen porti.[60]

2019 yilda Aleph fermasi Xalqaro kosmik stantsiyada yer yuzidan 248 milya (399 km) balandlikda go'shtni etishtirish uchun 3D bioprinting echimlari bilan hamkorlik qildi. Bu 3D-printer yordamida go'sht hujayralarini iskala ustiga ekstruziya qilish orqali amalga oshirildi.[61]

2020 yil yanvar oyida, Kvarts "dunyo bo'ylab 30 ga yaqin madaniy startaplar" mavjudligini ta'kidladilar va Memfis Meatz, Just Inc va Future Meat Technologies eng ilg'or kompaniyalar edi, chunki ular birinchi tajriba zavodlarini qurmoqdalar.[62] Ga binoan Yangi olim 2020 yil may oyida "butun dunyoda go'shtli go'shtni etishtirish jarayonini rivojlantiruvchi va takomillashtiruvchi 60 ga yaqin boshlang'ich tashkilot" mavjud edi. Ulardan ba'zilari o'zlari hech qanday toza go'sht ishlab chiqarmadilar, ammo boshqalarga eng so'nggi texnologik vositalar yoki eksperimental ma'lumotni taqdim etdilar.[63] Ma'lumotlarga ko'ra o'sish ommaviy axborot vositalari hali ham "litri uchun yuzlab dollar turadi, ammo toza go'sht ishlab chiqarish uchun uni litri 1 dollarga tushishi kerak".[63] 2020 yil iyun oyida Xitoy hukumati rasmiylari Xitoyni madaniy go'sht bo'yicha yutuqlarga erishayotgan boshqa mamlakatlar bilan hamqadam bo'lishiga imkon beradigan milliy strategiyani ishlab chiqishga chaqirishdi.[64]

Bozorga kirish

2020 yil 2-dekabr kuni Singapur oziq-ovqat agentligi tijorat savdosi uchun Eat Just tomonidan ishlab chiqarilgan "tovuq chaqishi" ni ma'qulladi. Bu birinchi marta madaniy go'sht mahsuloti oziq-ovqat regulyatorining xavfsizligi tekshiruvidan o'tganligi va o'nlab yillar davomida olib borilgan izlanishlar va ishlanmalardan so'ng sanoatning bozorga kirishi uchun muhim voqea sifatida baholandi. Singapur restoranlarida tovuq go'shti kichik hajmda kiritilishi rejalashtirilgan edi. Boshqa mahsulotlar, kompaniyalar va mamlakatlar nisbatan tez orada kuzatilishi kutilgan edi.[65]

Boshlang'ich korxonalarga umumiy nuqtai

Ushbu bo'lim uchun qo'shimcha iqtiboslar kerak tekshirish. (Oktyabr 2020) (Ushbu shablon xabarini qanday va qachon olib tashlashni bilib oling) |

Izoh: kursiv bilan sanalar kelajakda rejalashtirilgan yutuqlar sanalariga ishora qiladi; ular, ayniqsa, kechikishlar tufayli siljishi mumkin.

| Ism | Tashkil etilgan | Maydon | Fokus | So'nggi xarajatlar | Prototip | Uchuvchi zavod | Bozorga kirish |

|---|---|---|---|---|---|---|---|

| Aleph Farms | 2017[66] | Mol go'shti | $ 3000 / kg dan yuqori (2019 yil noyabr oyidagi da'vo)[67] | Dekabr 2018[66] | 2021 yilga rejalashtirilgan (Aprel 2020 da'vo)[68] | 2023 (Noyabr 2019 da'vo)[67] | |

| Appleton go'shtlari[iqtibos kerak ] | 2016 | Mol go'shti | |||||

| Artemys Foods[iqtibos kerak ] | 2019 | Go'sht | 2020 yil kuzi[69] | ||||

| Ovqatli go'sht | 2018[70] | Baliq maw | Noyabr 2019[71] | 2022 (Avgust 2020 da'vo)[70] | |||

| Biftek[iqtibos kerak ] | 2018 | Madaniyat vositalari | |||||

| BioBQ[iqtibos kerak ] | 2018 | Iskala | 2022[72] | ||||

| BlueNalu[iqtibos kerak ] | 2018 | Dengiz mahsulotlari | 2019 yil kuzi[73] | ||||

| Cell Ag Tech[iqtibos kerak ] | 2018 | Go'sht | |||||

| Cell Farm Food Tech[iqtibos kerak ] | 2018 | Go'sht | |||||

| Kubik ovqatlari[iqtibos kerak ] | 2018 | Yog ' | 2019 yil sentyabr[74] | ||||

| Faqat ovqatlaning | 2011 | Go'sht | S € 50 /nugget (Jan 2020 da'vo)[75] | 2017 yil dekabr[76] | 2019 yil o'rtalaridan boshlab qurilish (Jan 2020 da'vo)[62] | 2020 yil dekabr[65] | |

| Cheksiz ovqatlar | 2016[77] | Baliq | $ 7,000 / lb (Fevral 2018 da'vo)[78] | 2017 yil sentyabr[78] | [53] | ||

| Foieture loyihasi (6 ta kompaniya / notijorat tashkilot) | 2019 | Fuagra | € 15.000 / kg (may 2020 da'vo)[60] | 2020 (Dekabr 2019 da'vo)[59] | 2022 (Dekabr 2019 da'vo)[59] | 2023 (Dekabr 2019 da'vo)[59] | |

| Fork & Goode[iqtibos kerak ] | 2018 | Go'sht | |||||

| Kelajakdagi maydonlar[iqtibos kerak ] | 2017 | Madaniyat vositalari | |||||

| Future Meat Technologies | 2018 | Go'sht | $ 10 / funt (2022 yilga qadar 2020 yil fevraldagi gol)[79] | 2019 | 2019 yil oktyabr oyidan beri bunyod etilmoqda[62][80] | 2022 (Oktyabr 2019 da'vo)[81] | |

| Gaia Foods[iqtibos kerak ] | 2019 | Qizil go'sht | |||||

| Gurmey[iqtibos kerak ] | 2019 | Fois gras | |||||

| Heuros[iqtibos kerak ] | 2017 | Uy hayvonlari uchun oziq-ovqat | |||||

| Yuqori steyklar | 2017 | Cho'chqa go'shti | £ 'Ming' / kg (2020 yil iyul) da'vo[82] | Iyul 2020[83] | |||

| IntegriCulture, Inc. | 2015 | Fuagra | ¥ 20,000 / kg (2019 yil iyul oyidagi da'vo)[84] | 2021[85] | 2021 (Iyul 2020 da'vo) | ||

| Matritsa go'shtlari[iqtibos kerak ] | 2019 | Iskala | 2020[86] | ||||

| Go'shtli | 2018 | Cho'chqa go'shti | 2020 (Jan 2020 da'vo)[87] | 2022 yil boshlarida rejalashtirilgan (Fevral 2020 da'vo)[88] | 2022 (Jan 2020 da'vo)[87] | ||

| Memfis go'shtlari | 2015 | Parrandachilik | $ 1,700 / lb (Fevral 2018 da'vo)[89] | 2016 yil fevral[90] | 2020 yil yanvar oyidan beri qurilmoqda[62][80] | Taxminan 2020 yil (Fevral 2017 da'vo)[91] | |

| Mirai Foods | 2020 | Mol go'shti | 'Kichik mashina' / kg (iyun 2020 da'vo)[92] | Iyun 2020[92] | |||

| Mosa go'shti / Maastrixt universiteti | 2015 | Mol go'shti | € 60 / kg (2020 yilga qadar 2017 yil fevraldagi maqsad)[91] '88x arzonroq "(iyul 2020 da'vo)[93] | 2013 yil avgust (UM )[40] | 2020 yil may oyidan beri o'rnatilmoqda[93] | 2022 (Fevral 2020 da'vo)[94] | |

| Motif FoodWorks | 2019[95] | Mol go'shti | 2020 yil tugaydi (Avgust 2020 da'vo)[96] | 2021-chorak (mol go‘shti ta’mi) (Oktyabr 2020 da'vo)[97] | |||

| Multus Media[iqtibos kerak ] | 2019 | Madaniyat vositalari | Oktyabr 2019[98] | ||||

| Yangi asr go'shtlari | 2018[99] | Cho'chqa go'shti | 2018 yil sentyabr[100] | 2020 yil iyulidan keyin qurilish[99] | |||

| Go'shtni qayta aniqlang | 2018[66] | Mol go'shti | $ 35 / kg (sentyabr 2019 da'vo)[66] | 2019 yil sentyabr[66] | |||

| SavorEat | 2016[66] | Mol go'shti | 2021 yil o'rtalarida (restoranlar) (May 2020 da'vo)[66] | ||||

| Shiok go'shtlari | 2018[101] | Mayda qisqichbaqa | $ 3500 / kg (oktyabr 2020 da'vo)[102] | 2019[102] | 2021 (2020 yil mart oyidagi da'vo)[103][101][104] | ||

| SuperMeat | 2015[66] | Parrandachilik | 2018[105] | 2022 yilgacha (May 2020 da'vo)[66] | |||

| VOW oziq-ovqat mahsulotlari | 2019[106] | Kenguru | 1350 AQSh dollari / kg (avgust 2019 da'vo)[107] | 2019 yil avgust[107] | 2021 (restoranlar) (Oktyabr 2019 da'vo)[108] | ||

| Yovvoyi Yer[iqtibos kerak ] | 2017 | Uy hayvonlari uchun oziq-ovqat | |||||

| Yovvoyi tip | 2016 | Qo'shma Shtatlar | Dengiz mahsulotlari |

Bu kabi kompaniyalardan tashqari, notijorat tashkilotlari Yangi hosil, Yaxshi oziq-ovqat instituti va Uyali qishloq xo'jaligi jamiyati madaniy go'shtni himoya qilish, moliyalashtirish va tadqiq qilish.[109]

U qanday ishlaydi

Hujayra chiziqlari

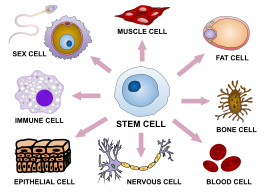

Uyali qishloq xo'jaligining birinchi komponenti hujayra liniyalarini, umuman, ildiz hujayralarini olishdir. Ildiz hujayralari - bu turli xil ixtisoslashgan hujayralar turlarining ko'pchiligiga yoki barchasiga aylanish qobiliyatiga ega bo'lgan farqlanmagan hujayralar. Totipotent ildiz hujayralari tanada mavjud bo'lgan barcha hujayralarni ajratish qobiliyatiga ega. Pluripotent ildiz hujayralari har xil hujayra turlariga kirib borishi mumkin, platsentadagi hujayralarni saqlab qolishi mumkin va ko'p potentsial ildiz hujayralari cheklangan nasab doirasida bir nechta turli xil ixtisoslashgan hujayralarga ajralib turishi mumkin. Yagona potentsial ildiz hujayralari faqat bitta aniq hujayra taqdiriga qarab ajralib turishi mumkin.[110]

Pluripotent ildiz hujayralari go'sht tarkibidagi har xil turdagi to'qimalarni tiklash uchun ideal bo'lsa-da, ushbu pastki toifaning eng ko'zga ko'ringan namunasi embrional ildiz hujayralari bo'lib, ular axloqiy masalalar tufayli tadqiqotlarda foydalanilganda ziddiyatli hisoblanadi. Natijada, olimlar induratsiyalangan pluripotent ildiz hujayralarini (iPSC) ishlab chiqdilar - asosan ko'p kuchliroq qon va teri hujayralari, ular yana pluripotent holatiga qayta dasturlashtirilgan, shuning uchun ularni juda ko'p ixtisoslashgan hujayralarga ajratish imkonini beradi.[111] Shu bilan bir qatorda mushak hujayralari avlodlarini keltirib chiqaradigan yoki potentsial bo'lmagan avlodlar paydo bo'lishiga yo'naltirilgan, ko'p miqdordagi katta hujayralar yordamida to'g'ridan-to'g'ri mushak hujayralariga ajralib chiqadi.[110]

Ildiz hujayralarining qulay xususiyatlariga o'lmaslik, yuqori proliferativ qobiliyat, yopishqoqlikka ishonmaslik, sarum mustaqilligi va to'qima ichiga osonlikcha ajratish kiradi. Biroq, bunday xususiyatlarning tabiiy mavjudligi hujayralar turlari va kelib chiqishi o'rtasida farq qilishi mumkin. Shunday qilib, quyidagi bosqichlar in vitro etishtirish ma'lum bir hujayra chizig'ining aniq ehtiyojlarini qondirish uchun sozlanishi kerak. O'lmaslikka kelsak, hujayralar, tabiiy ravishda, bo'linish chegarasini belgilaydilar, bu ularning telomer qopqog'i bilan belgilanadi - ularning xromosomalari oxiriga qo'shilgan qo'shimcha nukleotid asoslari. Har bir bo'linish bilan telomer qopqog'i mavjud bo'lmaguncha tobora qisqarib boradi, bu holda hujayra bo'linishni to'xtatadi. Pluripotensiyani keltirib chiqarish orqali telomer qopqog'ini cho'zish mumkin, shunday qilib hujayra abadiy bo'linadi.[111] Entomokulturada ishlatiladigan hasharotlar hujayralari, tabiiy ravishda, sarumga asoslangan madaniy muhitga va yopishqoqlikka bog'liq emas, shuning uchun sutemizuvchilar hujayralariga nisbatan suspenziya madaniyatida zichroq o'stirilishi mumkin.[112]

Hujayra chiziqlari asosiy manbadan to'planishi mumkin: ya'ni lokal behushlik ostida hayvonga biopsiya orqali. Ular, shuningdek, ikkilamchi manbalardan, masalan, kriyopreservlangan madaniyatlardan (avvalgi tadqiqotlar natijasida muzlab qolgan madaniyatlar) o'rnatilishi mumkin.[iqtibos kerak ]

O'sish muhiti

Hujayra chiziqlari o'rnatilgandan so'ng, ular ko'payish uchun madaniy muhitga botiriladi. Madaniy muhit odatda hujayralarni o'sishi uchun zarur bo'lgan barcha kerakli uglevodlar, yog'lar, oqsillar va tuzlar bilan ta'minlaydigan bazal muhitdan hosil bo'ladi. Bir marta hujayra etarli miqdorda iste'mol qilsa, u bo'linadi va populyatsiya haddan tashqari ko'payadi. Madaniyat vositalarini o'sishning qo'shimcha omillarini ta'minlovchi boshqa qo'shimchalar bilan to'ldirish mumkin, masalan, sarumlar. O'sish omillari ba'zi hujayralardagi jarayonlarni boshqarishda muhim ahamiyatga ega bo'lgan oqsil yoki steroidlarni ajratishi mumkin.[1] Odatda o'sish omillari madaniy muhitga xomilalik sigir zardobini (FBS) yoki boshqa hayvonlarga asoslangan sarumni yoki rekombinant oqsillarni ishlab chiqarish orqali qo'shiladi.[iqtibos kerak ]

Differentsiatsiya boshlangandan so'ng, mushak tolalari siqila boshlaydi va sut kislotasini hosil qiladi. Hujayralarning ozuqa moddalarini qabul qilishi va qisman ko'payishi ularning atrof-muhit pH qiymatiga bog'liq. Buning uchun sut kislotasi muhitda to'planib borishi bilan atrof-muhit tobora kislotali bo'lib, optimal pH darajasidan pastga tushadi. Natijada, madaniyat vositalari tez-tez tizimdan tozalanishi va almashtirilishi kerak. Bu, shuningdek, bazal muhitdan ozuqa moddalarining kontsentratsiyasini yangilash uchun ham foydalidir, chunki ular kengayib boruvchi hujayralar populyatsiyasi tomonidan doimiy ravishda kamayadi.[7]

Iskala

Ushbu bo'lim uchun qo'shimcha iqtiboslar kerak tekshirish. (Oktyabr 2020) (Ushbu shablon xabarini qanday va qachon olib tashlashni bilib oling) |

Tarkibiy go'sht mahsulotlariga nisbatan - nafaqat mavjud bo'lgan hujayralar turi, balki ularning umumiy konfiguratsiyasi bilan ajralib turadigan mahsulotlar - hujayralar iskala ichiga ekilgan bo'lishi kerak. Iskala - bu asosan hujayralarni aks ettirish va ularni kattaroq tuzilishga undashga qaratilgan qoliplar. Hujayralar rivojlanganda jonli ravishda, ularga hujayradan tashqari matritsa (ECM) bilan o'zaro ta'sirlar ta'sir qiladi. ECM - bu glikoproteinlar, kollagen va fermentlarning hujayralarga mexanik va biokimyoviy ko'rsatmalarini uzatishga mas'ul bo'lgan 3 o'lchovli mash. O'rmonlar ECM xususiyatlarini simulyatsiya qilishlari kerak.[1]

G'ovaklik. Teshiklar - iskala yuzasida bir necha daqiqali teshiklar. Ular to'qimalarning rivojlanishiga xalaqit beradigan oldindan mavjud bo'lgan hujayra tarkibiy qismlarini chiqarish uchun biomaterial yuzasida tartibda yaratilishi mumkin. Ular, shuningdek, yopishqoq hujayralarning ichki qatlamlariga tarqaladigan gaz va ozuqaviy moddalarni "nekrotik markaz" ni rivojlanishiga to'sqinlik qilishga yordam beradi (ozuqa moddalarining etishmasligi tufayli to'g'ridan-to'g'ri madaniy muhit bilan aloqada bo'lmagan hujayralar nobud bo'lganda hosil bo'ladi).[113]

Qon tomirlari. O'simliklarda uchraydigan qon tomir to'qimalarida suyuqlikni ichki tashish uchun mas'ul organlar mavjud. Miyoblastlarning tabiiy fiziologik holatini takrorlash orqali hujayralarni tekislashiga yordam beradigan arzon narxlardagi tabiiy topografiyalarni hosil qiladi. Bundan tashqari, u gaz va ozuqa almashinuvida yordam berishi mumkin.[113]

Biokimyoviy xususiyatlar. Iskala biokimyoviy xususiyatlari ECM xususiyatlariga o'xshash bo'lishi kerak. U to'qimalarning fazilatlari yoki kimyoviy birikmalar orqali hujayralarni yopishishini osonlashtirishi kerak. Bundan tashqari, u hujayralarni differentsiatsiyasini rag'batlantiradigan kimyoviy belgilarni ishlab chiqarishi kerak. Shu bilan bir qatorda, material ushbu funktsional xususiyatlarga ega bo'lgan boshqa moddalar bilan aralashishi kerak.[113]

Kristallik. Materialning kristallik darajasi qat'iylik kabi fazilatlarni belgilaydi. Yuqori kristallik vodorod bog'lanishiga taalluqli bo'lib, u o'z navbatida termal barqarorlikni, tortishish kuchini (iskala shaklini saqlash uchun muhim), suvni ushlab turishni (hujayralarni namlantirish uchun muhim) va yosh modulni oshiradi.[113]

Degradatsiya. Ba'zi materiallar hujayralar uchun foydali bo'lgan birikmalarga aylanadi, ammo aksincha, bu degradatsiya hujayralar uchun ahamiyatsiz yoki zararli bo'lishi mumkin. Parchalanish iskala tayyor mahsulotdan osongina hayvonlar to'qimasi bo'lishi uchun uni osonlikcha olib tashlashga imkon beradi va shu bilan uning o'xshashligini oshiradi. jonli ravishda go'sht. Ushbu degradatsiyani mushak to'qimalariga ta'sir qilmaydigan ba'zi fermentlar ta'sirida keltirib chiqarish mumkin.[113]

Ovqatlanish qobiliyati. Agar iskala hayvon to'qimasidan chiqarilmasa, iste'molchilar xavfsizligini ta'minlash uchun ular qutulish kerak. Shu tarzda, ular ozuqaviy tarkibiy qismlardan tayyorlangan bo'lsa ham foydali bo'ladi.[113]

2010 yildan buyon bir qator ilmiy tadqiqot guruhlari va kompaniyalari paydo bo'lib, qanday xom ashyoning o'ziga xos iskala xususiyatiga ega ekanligini va ularni qanday qilib skeletga aylantirish kerakligini aniqladi.[113][114][115][116][117][118]

Tsellyuloza tabiatda eng ko'p tarqalgan polimer bo'lib, o'simlik barglarining ekzoskeletlarini tashkil qiladi. Uning mo'lligi tufayli uni nisbatan arzon narxlarda olish mumkin. Bundan tashqari, u ko'p qirrali va biokompatibildir. "Dekellularizatsiya" deb nomlangan jarayon orqali u SDS sirt faol moddasida qoplanadi, bu esa teshiklarni hosil qiladi. Keyin bu teshiklar o'simlikning hujayra tarkibiy qismlarini chiqaradi va u dekellularizatsiya qilingan o'simlik to'qimalariga aylanadi. Ushbu material Patting guruhi akademik tadqiqotchilari va Ottava universiteti va Vodester Politexnika institutida Gaudette guruhi tomonidan keng o'rganilgan. O'zaro bog'lanish orqali (ularni bir-biriga bog'lab turish uchun alohida polimer zanjirlari o'rtasida kovalent bog'lanishlar hosil qilish) o'simlik to'qimalarining mexanik xususiyatlarini skelet mushaklari to'qimalariga ko'proq o'xshash bo'lishi uchun o'zgartirish mumkin. Bu o'simlik to'qimasini boshqa materiallar bilan aralashtirish orqali ham amalga oshirilishi mumkin. Boshqa tomondan, dekellularizatsiya qilingan o'simlik to'qimalarida odatda sutemizuvchilarning biokimyoviy belgilari yo'q, shuning uchun uni kompensatsiya qilish uchun boshqa funktsional oqsillar bilan qoplash kerak. Shu bilan birga, C2C12 o'sishi yalang'och iskala va kollagen yoki jelatin oqsillari qoplamasi bilan bir xil iskala o'rtasida sezilarli darajada o'zgargani ko'rsatilmagan. Ammo, ekish samaradorligi (hujayralar iskala bilan birikish darajasi) yaxshilandi. Dellularizatsiyalangan o'simlik to'qimalarining afzalligi - bu barglardagi qon tomirlarining tabiiy topografiyasi. Bu miyoblastlarning tabiiy fiziologik holatini takrorlashga yordam beradi, bu hujayralarni tekislashiga yordam beradi. Buning boshqa usullari odatda biroz qimmatroq, jumladan 3d bosma, yumshoq litografiya va fotolitografiya. Vaskulyarizatsiya, shuningdek, mushak konglomeratlarida odatda nekrotik markazlarni ishlab chiqaradigan hujayralardagi madaniy muhitning 100-200 nm diffuziya chegarasini engishga yordam beradi. Buning yana bir usuli - angiogenezni (yangi qon tomirlarini rivojlanishini) qo'llab-quvvatlovchi g'ovakli iskala. Bu Apple Hypanthium uchun ishlashi isbotlangan bo'lsa-da, barcha o'simliklar deyarli gözenekli emas. O'simliklar tsellyulozasiga alternativa bakterial tsellyuloza bo'lib, u odatda o'simlik tsellyulozasiga qaraganda toza, chunki u lignin va gemitselluloza kabi ifloslantiruvchi moddalardan xoli. Bakterial tsellyuloza polimer iplari orasida ko'proq vodorod bog'lanishiga ega va shuning uchun u ko'proq kristalga ega. Bundan tashqari, u kichikroq mikrofibrillalarga ega, bu esa ko'proq namlikni saqlashga va kichik teshiklarga ega bo'lishga imkon beradi. Moddaning o'zi chiqindilarni uglevodlar yordamida ishlab chiqarilishi mumkin (bu unga arzon narxda erishish mumkinligini taxmin qilishi mumkin) va u emulsiya qilingan go'shtda sharbat va chaynashni keltirib chiqaradi (bu hatto uni oxirgi mahsulotdan chiqarib bo'lmaydigan bo'lsa ham, u tekstura profiliga hissa qo'shadi).[113][114]

Chitin tabiatda eng ko'p tarqalgan ikkinchi polimer bo'lib, qisqichbaqasimonlar va qo'ziqorinlarning ekzoskeletlarida uchraydi. Uyali qishloq xo'jaligi hayvonlarga ishonchsiz bo'lishga qiziqqanligi sababli, qo'ziqorinlardan olingan xitin ko'proq qiziqish uyg'otadi. U asosan yuqorida aytib o'tilgan Pelling Group tomonidan o'rganilgan. Xitosan gidroksidi deatsetilatsiya (ma'lum aminokislota guruhlarini almashtirish) deb ataladigan jarayonda xitindan olinadi. Ushbu jarayonning darajasi xitosanning fizikaviy va kimyoviy xususiyatlarini aniqlaydi. Xitosan antibakterial xususiyatlarga ega, xususan, planktonik bakteriyalar va biofilmlarga bakteritsid ta'sir ko'rsatadi va bakteriyalar E.coli kabi gramm salbiy bakteriyalarga statik ta'sir ko'rsatadi. Bu juda muhim, chunki ko'plab iste'molchilar undan uzoqroq turishni afzal ko'rgan antibiotiklardan foydalanmasdan odamlar uchun zararli bo'lgan birikmalarni zararsizlantirishadi. Xitozanning glikozaminoglikanlarga o'xshashligi va glikoproteidlar va proteoglikanlarning ichki o'zaro ta'siri uni yuqori darajada biologik mos keladi. Yana bioaktiv omillarni tanlash uchun uni boshqa polimerlar bilan osonlikcha aralashtirish mumkin. Xitozanning potentsial kamchiliklaridan biri shundaki, u lizozimlar (tabiiy ravishda uchraydigan fermentlar) ishtirokida parchalanadi. Ammo, deatsetilatsiya jarayoni yordamida bunga qarshi turish mumkin. Bu butunlay salbiy narsa emas, chunki degradatsiya natijasida hosil bo'lgan yon mahsulotlar yallig'lanishga qarshi va bakteriyalarga qarshi xususiyatlarga ega. Buzilish bilan tuzilish uchun hujayralar matritsaga tayanadigan darajaga mos kelish juda muhimdir.[113]

Kollagen biriktiruvchi to'qimalarning asosiy tuzilishini tashkil etadigan oqsillar oilasi. Odatda sigir, cho'chqa go'shti va murin manbalaridan olinadi. Bularning barchasi hayvonot manbalari bo'lgani uchun, uyali qishloq xo'jaligi buni kollagenni tashkil etuvchi aminokislota takrorlanishini ishlab chiqarishga qodir transgen organizmlar yordamida engib chiqadi. Kollagen tabiiy ravishda Kollagen I tipida mavjud bo'lib, topografik belgilar va biokimyoviy xususiyatlarga ega bo'lgan gözenekli gidrojeller, kompozitler va substratlar sifatida ishlab chiqarilgan. Sintetik kollagen turlari, shuningdek, rekombinant oqsillarni ishlab chiqarish natijasida hosil bo'lgan - II va III kollagen turi, tropoelastin va fibronektin. Ushbu oqsillarning asosiy muammolaridan biri shundaki, ularni post tarjimasini o'zgartirish mumkin emas. Shu bilan birga, kollagenning biokimyoviy ko'rsatmalariga ega bo'lmagan, ammo genning o'ziga xos xususiyatiga ega bo'lgan mikroblarda muqobil fibrillyar oqsil ajratilgan. Rekombinatlangan kollagen ishlab chiqarishning asosiy yo'nalishi hosilni optimallashtirishdir - uni qanday qilib eng samarali ishlab chiqarish mumkin. O'simliklar, xususan, tamaki eng istiqbolli variantga o'xshaydi, ammo bakteriyalar va xamirturushlar ham alternativa hisoblanadi.[113]

To'qimalangan soya oqsili - bu tez-tez o'simlik tarkibidagi go'shtda ishlatiladigan soya un mahsulotidir, bu Isroil Texnologiya Institutidagi Levenberg guruhi tomonidan sigir hujayralarining o'sishini qo'llab-quvvatlagan. Uning shimgichli tuzilishi hujayraning samarali urug'lanishini ta'minlaydi va g'ovakliligi kislorod uzatilishini rag'batlantiradi. Bundan tashqari, u hujayralarni differentsiatsiyasi jarayonida ba'zi hujayralar uchun foydali birikmalarga aylanadi.[115]

Miselyum qo'ziqorinlarning ildizlari. Altast Foods Co. miselyum iskala qismida qo'ziqorin to'qimasini etishtirish uchun qattiq fermentatsiyadan foydalanadi. Keyin ular ushbu to'qimalarni yig'ib, undan pastırma analoglarini yaratish uchun foydalanadilar.[116]

Nanomateriallar nanobashkada noyob xususiyatlarni namoyish etadigan materiallardir. Biomimetic Solutions - hozirda SoSV inkubatori bilan shug'ullanadigan London asosidagi iskala - iskala yaratish uchun nanomateriallardan foydalanmoqda.[115]

Avstraliyaning Pert shahridagi Cass Materials kompaniyasi o'zlarining BNC iskala uchun nanosellyuloza gubkalarini yaratish uchun Nata de Coco (kokos yong'og'idan olingan) deb nomlangan xun tolasidan foydalanmoqda. Nata de Coco bio-mos keladi, g'ovakliligi yuqori, hujayralarning yopishishini osonlashtiradi va biologik parchalanadi.[117]

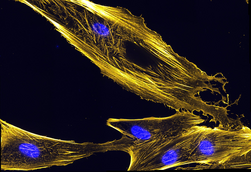

Immersion Jet Spinning - dastlab Garvard Universitetidagi Parker Group tomonidan ishlab chiqilgan polimerlarni tolalarga aylantirish orqali iskala yaratish usuli. iRJS platformasi aylanadigan suv omboridagi teshik orqali polimer eritmasini chiqarib olish uchun markazdan qochiruvchi kuch ishlatadi. Ekstruziya paytida eritma reaktivni hosil qiladi, u havo oralig'idan otilganda uzayadi va tekislanadi. Reaktiv girdob bilan boshqariladigan yog'ingarchilik vannasiga yo'naltiriladi, u kimyoviy yo'l bilan bog'lanadi yoki polimer nano tolalarini cho'ktiradi. Havo bo'shlig'i, aylanish va eritma kabi parametrlarni sozlash orqali hosil bo'lgan tolalarning diametrini o'zgartirishimiz mumkin. Ushbu usul PPTA, neylon, DNK va nanofiber plitalardan skafoldlarni aylantirishi mumkin. Nanofibröz iskala alginat va jelatindan shunday yo'l tutganki, C2C12 hujayralarining o'sishini qo'llab-quvvatlagan. Quyon va sigir aortasining silliq mushaklari mioblastlari ham jelatin tolalariga yopishib olishga qodir edi. Qisqa tolalarda agregatlar, uzunroqlarida esa to'qima hosil bo'ldi.[118]

Matrix Meats deb nomlangan kompaniya elektrospinning usulidan foydalanadi - zaryadlangan polimerlarni iskala uchun tolalarga aylantirish uchun elektr kuchidan foydalanadigan jarayon. Ularning iskala go'shtlari ebruga yo'l qo'yishi, bir nechta hujayralar qatoriga mos kelishi va o'lchovli ekanligi isbotlangan.[119]

Qo'shimchalar ishlab chiqarish

Mushak to'qimasini tuzishning yana bir taklif qilingan usuli qo'shimchalar ishlab chiqarish. Such a technique has already been perfected for industrial applications in manufacturing objects made out of plastic, nylon, metal, glass and other synthetic materials. The most common variation of the process involves incrementally depositing a filament in layers onto a bed until the whole object is created. This method will most likely lend itself best to the application of cultured meat as opposed to other types such as binder jetting, material jetting or stereolithography which require a specific kind of resin or powder.[iqtibos kerak ]

In this instance, a filament of muscle cells can be printed into a structure meant to resemble a finished meat product which can then be further processed for cell maturation. This technique has been demonstrated in a collaboration between 3D bioprinting solutions and Aleph Farms which successfully used additive manufacturing to structure turkey cells on the International Space Station.[120]

Bioreaktorlar

Scaffolds are placed inside bioreactors so that cell growth and specialization can occur. Bioreactors are large machines similar to brewery tanks which expose the cells to a large variety of environmental factors that are necessary to promote either proliferation or differentiation. The temperature of the bioreactor must replicate jonli ravishda shartlar. In the case of mammalian cells, this requires heating to 37 degrees Celsius. Alternatively, insect cells can be grown at room temperature. Most bioreactors are maintained at 5% carbon dioxide.[1][112]

Cells can either be cultivated in continuous or fed-batch systems. The former entails inoculating and harvesting cells in a constant process so that there are always cells in the bioreactor. Fed-batch systems mean inoculating the cells, culturing them and harvesting them in one distinct period.[1]

Stirred tank bioreactors are the most widely used configuration in which an impeller increases the flow, thereby homogenizing the culture media and a diffuser facilitates the exchange of oxygen into the media. This system is generally used for suspended cultures but can also be used for cells that require attachment to another surface if microcarriers are also included. Fixed bed bioreactors are commonly used for adherent cultures. They feature strips of fibres that are packed together to form a bed to which cells can attach. Aerated culture media is circulated through the bed. In airlift bioreactors, the culture media is aerated into a gaseous form using air bubbles which are then scattered and dispersed amongst the cells. Perfusion bioreactors are common configurations for continuous cultivation. They continuously drain media saturated with lactic acid that is void of nutrients and fill it with replenished media.[121]

Fermentatsiya

The elements outlined above apply to the cultivation of animal muscle tissue. However, cellular agriculture also extends to “acellular agriculture” which involves the production of animal products synthesized of non-living material. Such products include milk, honey, eggs, cheese, gelatin which are made of various proteins rather than cells. In such cases, these proteins must be fermented much like in recombinant protein production, alcohol brewing and the generation of many plant-based products like tofu, tempeh and sauerkraut.[122]

Firstly, as proteins are coded for by specific genes, the genes encoding for the protein of interest are synthesized into a plasmid - a closed loop of double helical genetic information. This plasmid, called the recombinant DNA, is then inserted into a bacterial specimen using genetic transformation. For this to happen, the bacteria needs to be competent (i.e. able to intake foreign, extracellular DNA) and able to horizontally transfer genes (i.e. integrate the foreign genes into its own DNA). Horizontal gene transfer is significantly more challenging in eukaryotic organisms than prokaryotic organisms because eukaryotic organisms have both a cell membrane and a nuclear membrane which the plasmid needs to penetrate whereas prokaryotic organisms only have a cell membrane. For this reason, prokaryotic bacteria are often favoured. In order to make such a bacteria temporarily competent, it can be exposed to a salt such as calcium chloride which neutralizes the negative charges on the cell membrane’s phosphate heads as well as the negative charges on the plasmid to prevent the two from repelling. Then, the bacteria can incubate in warm water, opening up large pores on the surface of the cell through which the plasmid can enter.[123]

Next, the bacteria is fermented on sugar which will encourage it to grow and duplicate and in the process it will express its DNA as well as the transferred plasmid resulting in protein.[124]

Finally, the solution is purified in order to separate out the residual protein. This can be done by introducing an antibody raised against the protein of interest which will kill bacteria cells not containing the protein. Through centrifugation, the solution can be spun around an axis with a sufficient amount of force to separate solids from liquids or it could be soaked in a well buffered ionic solution that employs osmosis to leach the water from bacteria and kill them.[125]

Qiyinchiliklar

O'sish omillari

The culture media is an essential component of in vitro etishtirish. It is responsible for providing the macromolecules, nutrients and growth factors necessary for cell proliferation. Sourcing growth factors is one of the most challenging aspects of cellular agriculture. Traditionally, it involves the use of fetal bovine serum (FBS) which is a blood product extracted from fetal dairy cows. Besides the argument that its production is unethical, it is also contradictory to the initial goal of cellular agriculture to be independent of the use of animals. It is also the most costly constituent of cultured meat, priced at around $1000 per litre. Furthermore, its chemical composition varies greatly depending on the animal, so it cannot be uniformly quantified chemically.[126] The reason fetal bovine serum is employed is because it conveniently mimics the process of muscle development jonli ravishda. The growth factors needed for tissue development are predominantly provided through an animal’s bloodstream, and there is no other known fluid which can single-handedly deliver all these components.[1]

The current alternative is to generate each of these growth factors individually using recombinant protein production. In this process, the genes coding for the specific factor are integrated into bacteria which is then fermented to express an abundance of the molecule. However, due to the added complexity of this process, it is particularly expensive.[1]

The ideal culture medium would be chemically quantifiable and accessible to ensure simplicity in production, cheap and not dependent on animals.[27] Such culture media will most likely be derived from plants and while this may reduce the possibility of transmitting infectious agents, there is also the possibility that they may induce allergic reactions in some consumers.[127] Such culture sera may also require modifications specific to the cell line to which it is applied. There are a variety of companies currently invested in developing effective plant based culture, including Future Fields, Multus Media and Biftek.[128][129][130]

Yuzaki maydon

A common challenge to bioreactors and scaffolds is developing system configurations that enable all cells to gain exposure to culture media while simultaneously optimizing spatial requirements. In the cell proliferation phase, prior to the introduction of the scaffold, many cell types need to be attached to a surface in order to support growth. As such, cells must be grown in confluent monolayers only one cell thick which necessitates a lot of surface area. This poses practicality challenges on large scales. As such, systems may incorporate microcarriers - small spherical beads of glass or other compatible material which are suspended in the culture medium. Cells adhere to these microcarriers as they would the sides of the bioreactor which increases the amount of available surface area.[131]

In the cell differentiation phase, the cells may be seeded to a scaffold and so do not require the use of microcarriers. However, in these instances, the density of the cells on the scaffold means that not all cells have an interface with culture media, leading to cell death and necrotic centers within the meat. When muscle is cultivated jonli ravishda, this issue is circumvented as the ECM delivers nutrients into the muscle through blood vessels. As such, many emerging scaffolds are aiming to replicate such networks.[131]

Similarly, scaffolds must simulate many of the other characteristics of the ECM, most notably porosity, crystallinity, degradation, biocompatibility and functionality. Few materials which emulate all these characteristics have been identified leading to the possibility of blending different materials with complementary properties.[113]

Tadqiqotni qo'llab-quvvatlash

As cellular agriculture is not widely considered a developed field, research does not have a significant basis of academic interest or funding streams.[8] Consequently, the majority of research in the space has been undertaken and funded by independent institutions. However, this is incrementally changing as non for profits drive support and interest in the field. Notably, New Harvest has a fellowship program to support the research of specific graduate students and groups at various academic institutions.[132]

Iste'molchilarni qabul qilish

Cultured meat will likely be exposed to the public on a global scale in the coming years, making consumer acceptance of the product an important concern.[133] Research is being done to identify how consumers will accept cultured meat into the market. A study looking at acceptance of cultured meat in China, India, and the USA "found high levels of acceptance of clean meat in the three most populous countries worldwide."[134]

Several potential factors of consumer acceptance of cultured meat have been identified. Healthiness, safety, nutritional characteristics, sustainability, taste, and lower price, are all potential factors.[135] One study found that the use of highly technical language to explain cultured meat led to significantly more negative public attitude towards the concept.[136] Similarly, it is suggested that describing cultured meat in a way that emphasizes the final product rather than the production method was an effective way to improve acceptance.[137] Low percentages of older adult populations have been reported to show acceptance for cultured meat. Green eating behavior, educational status, and food business, were cited as most important factors for this population.[138]

The use of standardized descriptions would improve future research about consumer acceptance of cultured meat. Current studies have often reported drastically different rates of acceptance of the product, despite surveying similar populations. More comparable research is considered a future goal for consumer acceptance studies of cultured meat.[139]

It is currently unknown how cultured meat will be received in worldwide markets. Large amounts of studies are attempting to determine the current levels of consumer acceptance and identify methods to improve this value. Currently there is a lack of clear answers surrounding this unknown, although a recent study has shown that consumers are to'lashga tayyor a premium for cultured meat.[140][141][136][138][135][137][142]

Qoidalar

Once cultured meat becomes more cost-efficient, it is necessary to decide who will regulate the safety and standardization of these products. Prior to being available for sale, the Yevropa Ittifoqi va Kanada will require approved novel food applications. Additionally, the European Union requires that cultured animal products and production must prove safety, by an approved company application, which became effective as of 1 January 2018.[143]

Ichida Qo'shma Shtatlar, FDA (Food and Drug Administration) and the USDA (United States Department of Agriculture) have agreed to jointly regulate cultured meat. Under the agreement, the FDA oversees cell collection, cell banks, and cell growth and differentiation, while the USDA oversees the production and labeling of human food products derived from the cells.[144]

Differences from conventional meat

Sog'liqni saqlash

Large-scale production of cultured meat may or may not require artificial o'sish gormonlari to be added to the culture for meat production.[145][146]

Researchers have suggested that omega-3 yog 'kislotalari could be added to cultured meat as a health bonus.[33] Xuddi shunday, omega-3 fatty acid content of conventional meat can also be increased by altering what the animals are fed.[147] Soni Vaqt magazine has suggested that the cell-cultured process may also decrease exposure of the meat to bacteria and disease.[34]

Due to the strictly controlled and predictable environment, cultured meat production has been compared to vertikal dehqonchilik, and some of its proponents have predicted that it will have similar benefits in terms of reducing exposure to dangerous chemicals like pesticides and fungicides, severe injuries, and wildlife.[148]

Concern in regards to developing antibiotic resistance due to the use of antibiotics in livestock, and livestock-derived meat serving as a major source of disease outbreaks (including bird flu, anthrax, swine flu, and listeriosis), and long-term processed meat consumption being associated with increased heart disease, digestive tract cancer, and type 2 diabetes currently plague livestock-based meat. In regards to cultured meat, strict environmental controls and tissue monitoring can prevent infection of meat cultures from the outset, and any potential infection can be detected before shipment to consumers.[149]

In addition to the prevention and lack of diseases and lack of the use of antibiotics, cultured meat can also leverage numerous biotechnology advancements, including increased nutrient fortification, individually-customized cellular and molecular compositions, and optimal nutritional profiles, all making it much healthier than livestock-sourced meat.[149]

Sun'iylik

Although cultured meat is real meat consisting of genuine animal muscle cells, fat and support cells, as well as blood vessels,[150] that are the same in traditional meat, some consumers may find the high-tech production process repugnant. Cultured meat has been described as fake or "Frankenmeat". Clean meat can be produced without the artificial hormones, antibiotics, steroids, medicine, and GMOs commonly used in factory farmed meat and seafood.[151]

If a cultured meat product is different in tashqi ko'rinish, ta'mi, hid, to'qima, or other factors, it may not be commercially competitive with conventionally produced meat. The lack of bone and cardiovascular system may be a disadvantage for dishes where these parts make appreciable culinary contributions. However, the lack of bones and/or blood may make many traditional meat preparations, such as buffalo qanotlari, more palatable to small children. Furthermore, cultured blood and bones could potentially be produced in the future as well.[152][153][154]

Atrof-muhit

There have historically been concerns from the United Nations about the unrelenting production of traditional meat production for the growing world population. Animal production for food has been one of the major causes of air/water pollution and global warming.[155] There is significant doubt that the traditional industry will be able to keep up with the rapidly increasing demands for meat, pushing many entrepreneurs and researchers towards development of cultured meat as an alternative.[156] Cultured meat looks to provide an environmentally conscious alternative to traditional meat production.[157]

Research has suggested that environmental impacts of cultured meat would be significantly lower than normally slaughtered beef.[158] For every hectare that is used for vertical farming and/or cultured meat manufacturing, anywhere between 10 and 20 hectares of land may be converted from conventional agriculture usage back into its natural state.[159] Vertical farms (in addition to cultured meat facilities) could exploit methane digesters to generate a small portion of its own electrical needs. Methane digesters could be built on site to transform the organic waste generated at the facility into biogaz which is generally composed of 65% methane along with other gasses. This biogas could then be burned to generate electricity for the greenhouse or a series of bioreactors.[160]

A study by researchers at Oxford and the University of Amsterdam found that cultured meat was "potentially ... much more efficient and environmentally-friendly", generating only 4% greenhouse gas emissions, reducing the energy needs of meat generation by up to 45%, and requiring only 2% of the land that the global meat/livestock industry does.[161][162] The patent holder Willem van Eelen,[163] jurnalist Brendan I. Koerner,[164] and Hanna Tuomisto, a PhD student from Oxford University all believe it has less environmental impact.[165] In Tuomisto's life cycle analysis done at the University of Helsinki, producing 1000 kg of meat conventionally is expected to require “26–33 GJ energy, 367–521 m³ water, 190–230 m² land, and emits 1900–2240 kg CO2-eq GHG emissions”. On the other hand, producing the same quantity of meat in vitro has “7–45% lower energy use… 78–96% lower GHG emissions, 99% lower land use, and 82–96% lower water use”.[166]

One skeptic is Margaret Mellon of the Xavotirga tushgan olimlar ittifoqi, who speculates that the energy and fossil fuel requirements of large-scale cultured meat production may be more environmentally destructive than producing food off the land.[31] However, S.L. Davis has speculated that both vertical farming in urban areas and the activity of cultured meat facilities may cause relatively little harm to the species of wildlife that live around the facilities.[167] Dikson Despommier speculated that natural resources may be spared from depletion due to vertical farming and cultured meat, making them ideal technologies for an aholi ko'p dunyo.[168] One study has shown that conventional farming kills ten wildlife animals per hectare each year.[167]

Role of genetic modification

Texnikalari gen muhandisligi, such as insertion, deletion, silencing, activation, or mutation of a gene, are not required to produce cultured meat. Cultured meat production allows the biological processes that normally occur within an animal to occur without the animal. Since cultured meat is grown in a controlled, artificial environment, some have commented that cultured meat more closely resembles hydroponic vegetables, rather than GMO vegetables.[169]

More research is being done on cultured meat, and although the production of cultured meat does not require techniques of genetic engineering, there is discussion among researchers about utilizing such techniques to improve the quality and sustainability of cultured meat. Fortifying cultured meat with nutrients such as beneficial fatty acids is one improvement that can be facilitated through genetic modification. The same improvement can be made without genetic modification, by manipulating the conditions of the culture medium.[170] Genetic modification may also play a role in the proliferation of muscle cells. The introduction of myogenic regulatory factors, growth factors, or other gene products into muscle cells may increase production past the capacity of conventional meat.[170]

To avoid the use of any animal products, the use of photosynthetic algae and cyanobacteria has been proposed to produce the main ingredients for the culture media, as opposed to the very commonly used fetal bovine or horse serum.[171] Some researchers suggest that the ability of algae and cyanobacteria to produce ingredients for culture media can be improved with certain technologies, most likely not excluding genetic engineering.[172]

Axloqiy

The Australian bioethicist Julian Savulescu said "Artificial meat stops cruelty to animals, is better for the environment, could be safer and more efficient, and even healthier. We have a moral obligation to support this kind of research. It gets the ethical two thumbs up."[173]Hayvonlarning farovonligi groups are generally in favor of the production of cultured meat because it does not have a nervous system and therefore cannot feel pain.[31][174][175] Reactions of vegetarians to cultured meat vary:[176] some feel the cultured meat presented to the public in August 2013 was not vegetarian as fetal calf serum was used in the growth medium.[177] However, since then lab grown meat has been grown under a medium that doesn't involve bovine serum.[178] American philosopher Carlo Alvaro argues that the question of the morality of eating in vitro meat has been discussed only in terms of convenience. Alvaro proposes a virtue-oriented approach that may reveal aspects of the issue not yet explored, such as the suggestion that the obstinacy of wanting to produce lab-grown meat stems from unvirtuous motives, i.e., "lack of temperance and misunderstanding of the role of food in human flourishing."[179]

Independent inquiries may be set up by certain governments to create a degree of standards for cultured meat.[180] Laws and regulations on the proper creation of cultured meat products would have to be modernized to adapt to this newer food product.[180] Some societies may decide to block the creation of cultured meat for the "good of the people" – making its legality in certain countries a questionable matter.[180]

Cultured meat needs technically sophisticated production methods making it harder for communities to produce food self-sufficiently and potentially increasing dependence on global food corporations.[181]

Diniy fikrlar

Yahudiy rabbinical authorities disagree whether cultured meat is kosher (food that may be consumed, according to Jewish dietary laws). However, many rabbis agree that if the original cells were taken from a slaughtered kosher animal then the cultured meat will be kosher.[iqtibos kerak ] Some even think that it would be kosher even if coming from non-kosher animals like pigs, as well as from live animals, however, some disagree.[11]

With the development of cultured meat as a potentially large-scale product in the coming years, concerns from the Islomiy faith regarding its viability are becoming increasingly important.[182] The Islamic Institute of Orange County in California has responded to the Islamic consumption of embryonic stem cell cultured meat saying, "There does not appear to be any objection to eating this type of cultured meat."[183] In addition, Abdul Qahir Qamar of the International Islamic Fiqh Academy is quoted saying that cultured meat "will not be considered meat from live animals, but will be cultured meat." He continues to define that excluding cells derived from pigs, dogs, and other halal banned animals, the meat would be considered vegetative and "similar to yogurt and fermented pickles."[183]

Debate in India over the Hindu consumption of cultured meat mainly excludes steak and burgers. Chandra Kaushik, president of the Hindu Mahasabha reports that he would "not accept it being traded in a marketplace in any form or being used for a commercial purpose."[183]

Iqtisodiy

At the moment, cultured meat is estimated to be significantly more costly than conventional meat - for instance, the first cultured burger in 2013 cost upwards of $330,000 USD. In a March 2015 interview with Australia's ABC, Mark Post said that the marginal cost of his team's original €250,000 burger was now €8.00. He estimates that technological advancements would allow the product to be cost-competitive to traditionally sourced beef in approximately ten years.[184] In 2016, the cost of production of cultured beef for food technology company Memfis go'shtlari was $18,000 per pound ($40,000/kg).[185] 2017 yil iyun holatiga ko'ra[yangilash], Memphis Meats reduced the cost of production to below $2,400 per pound ($5,280/kg),[186] in February 2018 to $1,700 per pound and even further after that.[89]

Still, the main cost driver in cultured meat is the culture media due to the incorporation of the aforementioned FBS and other animal sera or reliance on alternative protein production. This issue is compounded due to the quantity of culture media that is necessitated. There are a number of organizations working on decreasing the cost of culture media either by scaling recombinant protein production to make it more efficient or finding more cost-effective alternatives and configurations to current ingredients.

Uzluksiz rivojlanish

Ta'lim

Since Dr. Post successfully produced the first cultured meat burger in 2013, a variety of startups and organizations dedicated to developing or advancing cultured meat have been founded. In 2015, Maastricht University hosted the first International Conference on Cultured Meat.[187] Yangi hosil[188] - a 501(c)(3) research institute - as well as Yaxshi ovqat instituti[189] host annual conferences to convene industry leaders, scientists, investors, and potential collaborators from parallel industries. The two organizations also fund public research and produce educational content. Organizations such as the Cellular Agriculture Society, Cellular Agriculture Canada, Cellular Agriculture France, Cellular Agriculture Australia and Cellular agriculture New Zealand were founded to advocate for cultured meat in their respective countries. Publications such as Cell Agri and the Protein Report have also emerged in order to provide updates concerning the technology and business within the field.[iqtibos kerak ]

Tadqiqot

At Tufts University, PhD candidate Natalie Rubio is conducting research into the field of entomoculture – cellular agriculture specifically applied to culturing insect tissue. Insect cultures may have comparative benefits over mammalian cells in terms of their environmental tolerance, ability to proliferate in serum free media, ability to grow in suspension and increased nutritional profile. The aim of my research is to develop a three-dimensional culture system for insect tissue biofabrication with consideration for food applications and to do this, Natalie is focusing on (1) cell line development and serum-free media formulation, (2) scaffold fabrication and (3) nutrient and texture analysis. Also at Tufts University, PhD candidate and New Harvest Dissertation Awardee Mike McLelland has developed an interactome map of cardiac tissue in order to identify the active trophic factors provided to cells when they are grown in animal sera. The idea is to clone these trophic factors in other cells called “Trophic Support Cells” and coculture them alongside other cells. [190]

At the Newcastle University, Dr. Ricardo M Gouveia is investigating the effect of curved substrates on controlling the behaviour of stromal cells during growth in vitro. He has thus far found that curvature is a cost-effective way to promote migration, proliferation, and self-organization. Such characteristics will ultimately help to improve the palatability of culture meat.[190]

Fat is an integral component of inducing meat texture, taste and appeal however, a cultured meat product that features marbling - the interspersion of fat and muscle - has yet to be developed. Muscle and fat cells require different cues in order to grow effectively. At the University of California, Los Angeles, Stephanie Kaweki is working on tuning scaffold properties so that they can support the growth of both muscle and fat cells.[190]

At the University of Ottawa, the Pelling Lab is working on creating an open-source, plant-based scaffolding platform to support the 3D culture of mammalian cells promote cell invasion and proliferation, and retain shape and mechanical properties for several months in culture. They are specifically investigating plant cellulose as it is the most abundant polymer on earth. Thus far, they have achieved results demonstrating that such a material is effective at stimulating certain characteristics such as topography and vascularization.[190]

At Rice University, Andrew Stout is conducting research into the nutritional profile of cultured meat. Specifically, he is examining the possibility of using genetic engineering and bioprocessing techniques to enhance the nutritional quality of the resulting muscle tissue.[190]

To date, many of the bioreactors used in cultured meat research have been at lab scale. The bioreactors used at the industrial level must be larger and in order to design them, we have to better understand the parameters muscle tissue relies on. At the University of Bath, Scott Allan is aiming to understand reaction kinetics, transport phenomena, mass transfer limitations and metabolic stoichiometric requirements, to name a few.[190]

At Reutlinger University, PhD candidate Jannis Wollschlager is working on creating a meat bioprinting process that will process both muscle and fat. The technique will leverage computer assisted design models, co-culture media which support muscle and fat cells as well as animal free bio-inks suitable to the cell types.[190]

Accelerators and incubators

There are a variety of venture capital firms and accelerator/incubator programs which focus on assisting cultured technology startups, or plant-based protein companies in general. The Big Idea Ventures (BIV) Venture Capital firm has launched their New Protein Fund which invests in emerging cell and plant-based food companies in New York and Singapore. With plans to start their third round of accelerator companies in January 2021, they have previously invested in MeliBio, Actual Veggies, Biftek.co, Orbillion Bio, Yoconut, Evo, WildFor and Novel Farms, to name a few.[191] Indie Bio is a biology oriented accelerator program that has invested in Memphis Meats, Geltor, New Age Meats and Finless Foods. They are based in San Francisco and are currently running their 10th cohort of companies.[192]

Ommaviy madaniyatda

Badiiy adabiyotda

Ushbu bo'lim uchun qo'shimcha iqtiboslar kerak tekshirish. (May 2020) (Ushbu shablon xabarini qanday va qachon olib tashlashni bilib oling) |

Cultured meat has often featured in ilmiy fantastika. The earliest mention may be in Ikki sayyora (1897) tomonidan Kurd Lassvits, where "synthetic meat" is one of the varieties of synthetic food introduced on Earth by Martians. Other notable books mentioning artificial meat include Kul, kul (1943) tomonidan Rene Barjavel; Kosmik savdogarlar (1952) tomonidan Frederik Pol va SM. Kornblyut; Koinot oxiridagi restoran (1980) tomonidan Duglas Adams; Le Transperceneige (Snowpiercer) (1982) tomonidan Jak Lob va Jan-Mark Rochette; Neyromanser (1984) tomonidan Uilyam Gibson; Oryx va Crake (2003) tomonidan Margaret Atvud; Deadstock (2007) tomonidan Jeffri Tomas; Accelerando (2005) tomonidan Charlz Stross; Tetralogiya buyumlari tomonidan Rudi Raker; Turli xil (2011) tomonidan Veronika Rot; va Vorkosigan Saga (1986-2018) by Lois McMaster Bujold.[iqtibos kerak ]

In film, artificial meat has featured prominently in Giulio Questi 's 1968 drama La morte ha fatto l'uovo (O'lim tuxum qo'ydi) va Klod Zidi 's 1976 comedy L'aile ou la cuisse (Qanot yoki son). "Man-made" chickens also appear in Devid Linch 's 1977 surrealist horror, Eraserhead. Most recently, it was also featured prominently as the central theme of the movie Virusga qarshi (2012).[iqtibos kerak ]

The Starship Korxona from the TV and movie franchise Yulduzli trek apparently provides a synthetic meat or madaniy go'sht as a food source for the crew,[193] although crews from Keyingi avlod and later use replikatorlar.[iqtibos kerak ]

In ABC sitcom Teddan yaxshiroq (2009–2010), the episode "Qahramonlar " features Phil (Jonathan Slavin ) and Lem (Malkolm Barret ) trying to grow cowless beef.[iqtibos kerak ]

Video o'yinda Adan loyihasi, the player characters investigate a cultured meat company called Real Meat.[iqtibos kerak ]

In the movie "GalaxyQuest", during the dinner scene, Tim Allen's character refers to his steak tasting like "real Iowa beef".[iqtibos kerak ]

Yilda Kenglik “vat-grown” meat is produced to feed the people who live on spaceships/space stations away from Earth, due to the exorbitant cost of importing real meat.[iqtibos kerak ]

Cultured meat was a subject on an episode of the Kolbert hisoboti 2009 yil 17 martda.[194]

In February 2014, a biotech startup called BiteLabs ran a campaign to generate popular support for hunarmandchilik salom made with meat cultured from celebrity tissue samples.[195] The campaign became popular on Twitter, where users tweeted at celebrities asking them to donate muscle cells to the project.[196] Media reactions to BiteLabs variously identified the startup as a satire on startup culture,[197] celebrity culture,[198] or as a discussion prompt on bioethical concerns.[199] While BiteLabs claimed to be inspired by the success of Sergey Brin's burger, the company is seen as an example of muhim dizayn rather than an actual business venture.[iqtibos kerak ]

In late 2016, cultured meat was involved in a case in the episode "How The Sausage Is Made" of CBS ko'rsatish Boshlang'ich.[iqtibos kerak ]

Shuningdek qarang

- BioArt

- Cellular agriculture society

- Factory farming divestment

- Oziq-ovqat va ozuqa

- Cultured leather

- Go'sht o'rnini bosadigan moddalar ro'yxati

- Kvorn (oziq-ovqat mahsuloti)

- Resurslarni ajratish

- Uyali qishloq xo'jaligining xronologiyasi

- To'qimalar madaniyati

- Tayson ovqatlari

Adabiyotlar

- ^ a b v d e f g Datar, I (January 2010). "Possibilities for an in vitro meat production system". Innovative Food Science & Emerging Technologies. 11 (1): 13–22. doi:10.1016/j.ifset.2009.10.007.

- ^ Post, Mark (4 December 2013). "Medical technology to Produce Food". Oziq-ovqat va qishloq xo'jaligi fanlari jurnali. 94 (6): 1039–1041. doi:10.1002/jsfa.6474. PMID 24214798.

- ^ Edelman, PD (3 May 2005). "Commentary: In Vitro-Cultured Meat Productionsystem". To'qimachilik muhandisligi. 11 (5–6): 659–662. CiteSeerX 10.1.1.179.588. doi:10.1089/ten.2005.11.659. PMID 15998207. Olingan 8 aprel 2018.

- ^ Schonwald, Josh (May 2009). "Future Fillet". Chikago universiteti jurnali.

- ^ Chalmers University of Technology (7 September 2011). "Growing meat in the lab: Scientists initiate action plan to advance cultured meat". Science Daily.

- ^ Bekker, Gerben A.; Tobi, Hilde; Fischer, Arnout R.H. (July 2017). "Meet meat: An explorative study on meat and cultured meat as seen by Chinese, Ethiopians and Dutch". Tuyadi. 114: 82–92. doi:10.1016/j.appet.2017.03.009. PMID 28323057. S2CID 3936024.

- ^ a b "Future Food - In Vitro Meat". futurefood.org. Noyabr 2018. Olingan 26 noyabr 2018.

- ^ a b Rohrheim, A (June 2016). "Cultured Meat". Sentience siyosati. Arxivlandi asl nusxasi 2018 yil 1-dekabr kuni. Olingan 26 noyabr 2018.

- ^ Zaraska, Marta (19 August 2013). "Is Lab-Grown Meat Good for Us?". Atlantika.

- ^ Anthis, Jacy Reese (19 October 2018). "Slaughter-Free Meat Is An Answer To Our Cruel And Broken Food System". Huffington Post. Olingan 10 aprel 2019.

- ^ a b JTA. "Rabbi: Lab-grown pork could be kosher for Jews to eat – with milk". Times of Israel. Olingan 22 mart 2018.

- ^ Fountain, Henry (6 August 2013). "Laboratoriya sharoitida yetishtirilgan burger ta'mni sinab ko'radi". The New York Times. Olingan 2 fevral 2016.

- ^ "USDA and FDA to Host Joint Meeting On Cell-Based Meat Regulation". VegNews.com. Olingan 26 noyabr 2018.

- ^ Banis, Davide (14 December 2018). "7 Predictions On The Future Of Clean Meat in 2019". Forbes. Olingan 10 aprel 2019.

- ^ a b Watson, Elaine (12 September 2019). "'Cultivated' meat could be the most-consumer-friendly term for cell-cultured meat, suggests Mattson/GFI research". FoodNavigator-AQSh.

- ^ Jha, Alok (5 August 2013). "Synthetic meat: how the world's costliest burger made it on to the plate". Guardian. Olingan 2 fevral 2016.

- ^ ""Clean Meat": The "Clean Energy" of Food". 6 sentyabr 2016 yil.

- ^ ""Clean Meat," "Cell-Based Meat," "Slaughter-Free Meat": How We Talk About Meat Grown without Animals". Yaxshi ovqat instituti. 27 sentyabr 2018 yil. Olingan 14 oktyabr 2019.

- ^ "Lab-made meat rebranded 'clean meat' to address 'yuck' factor". GlobalMeatNews.

- ^ ""Clean meat" is catching on: a reflection on nomenclature". The Good Food Institute. 24 May 2018. Arxivlangan asl nusxasi 2018 yil 16 sentyabrda. Olingan 5 iyun 2018.

- ^ foodnavigator-usa.com. "Cultured meat cos agree to replace term 'clean meat' with 'cell-based meat' and form trade association". foodnavigator-usa.com. Olingan 14 oktyabr 2019.

- ^ foodnavigator-usa.com. "'Cell-based meat' not the most consumer-friendly term, reveals GFI consumer research". foodnavigator-usa.com. Olingan 14 oktyabr 2019.

- ^ Friedrich, Bruce (13 September 2019). "Cultivated Meat: Why GFI Is Embracing New Language". Yaxshi ovqat instituti. Olingan 14 oktyabr 2019.

- ^ Fifty Years Hence, The Strand Magazine (December 1931)

- ^ a b Frey, Thomas (30 May 2019). "The Future of the Cultured Meats Industry in 2040". Futurist Speaker. Olingan 20 noyabr 2019.

- ^ WO9931222 A1 Application WO9931222, van Eelen, Willem Frederik; Willem Jan van Kooten & Wiete Westerhof, "Industrial scale production of meat from in vitro cell cultures"[o'lik havola ]

- ^ a b Kadim, Isam T; Mahgoub, Osman; Baqir, Senan; Faye, Bernard; Purchas, Roger (February 2015). "Cultured meat from muscle stem cells: A review of challenges and prospects". Integral qishloq xo'jaligi jurnali. 14 (2): 222–233. doi:10.1016/S2095-3119(14)60881-9.

- ^ Shapiro, Paul (19 December 2017). "Laboratoriyada etishtirilgan go'sht yo'lda". Scientific American: Observations. Olingan 20 noyabr 2019.

- ^ Catts, Oron; Zurr, Ionat (Winter 2004–2005). "Ingestion / Disembodied Cuisine". Shkaf jurnali.

- ^ "Paper Says Edible Meat Can be Grown in a Lab on Industrial Scale" (Matbuot xabari). Merilend universiteti. 6 July 2005. Archived from asl nusxasi 2005 yil 25-iyulda. Olingan 12 oktyabr 2008.

- ^ a b v Levine, Ketzel (20 May 2008), Lab-Grown Meat a Reality, But Who Will Eat It?, Milliy jamoat radiosi, olingan 10 yanvar 2010

- ^ "PETA's 'In Vitro' Chicken Contest". PETA. 6 oktyabr 2008 yil. Olingan 5 dekabr 2019.

- ^ a b Makintayre, Ben (20 January 2007). "Test-tube meat science's next leap". Avstraliyalik. Arxivlandi asl nusxasi 2011 yil 2-noyabrda. Olingan 26 noyabr 2011.

- ^ a b Siegelbaum, D.J. (2008 yil 23 aprel). "Probirkadagi gamburgerni qidirishda". Vaqt. Olingan 30 aprel 2009.

- ^ "2009 yilning eng yaxshi 50 ta ixtirosi". Vaqt. 2009 yil 12-noyabr.

- ^ Rojers, Lois (2009 yil 29-noyabr). "Olimlar cho'chqa go'shtini laboratoriyada etishtirishadi". Sunday Times. London. Arxivlandi asl nusxasi 2010 yil 6-yanvarda. Olingan 8 dekabr 2009.

- ^ "Dunyoda laboratoriyada etishtirilgan birinchi burger Londonda iste'mol qilinadi". BBC yangiliklari. 2013 yil 5-avgust. Olingan 2 fevral 2016.

- ^ Favvora, Genri. "325 ming dollarlik In Vitro Burger-ga muhandislik qilish". Olingan 12 iyun 2018.

- ^ "Laboratoriya sharoitida yetishtirilgan go'shtning narxi pasayib, 2021 yilgacha har bir pattaga 280 000 dan 10 dollargacha tushadi".. VegNews.com. Olingan 29 noyabr 2019.

- ^ a b Hogenboom, Melissa (2013 yil 5-avgust). "Ildiz hujayra burgerining ta'mi nimada?". BBC yangiliklari. Olingan 2 fevral 2016.

- ^ a b "Kweekvlees en vleesvervangers - Rondetafelgesprek 26-9-2018". Arnews (golland tilida). Gollandiya Vakillar palatasi. 26 sentyabr 2018 yil. Olingan 23 oktyabr 2018.

- ^ Bunge, Jeykob (2016 yil 1-fevral). "Yaltiroq bifteklar yaqinda laboratoriyada o'sishi mumkin". The Wall Street Journal. Olingan 4 fevral 2016.

- ^ "'Dunyodagi birinchi "laboratoriyada etishtirilgan köfte aniqlandi". Fox News. Olingan 4 fevral 2016.

- ^ Addady, Mixal (2016 yil 2-fevral). "Siz faqat besh yilda laboratoriyada etishtirilgan go'shtni iste'mol qilishingiz mumkin". Baxt. Olingan 4 fevral 2016.